Three-drum washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of small single washing volume, inconvenient cleaning, waste of water and electricity, etc., and achieve the effect of saving water and electricity and meticulously sorting and cleaning clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

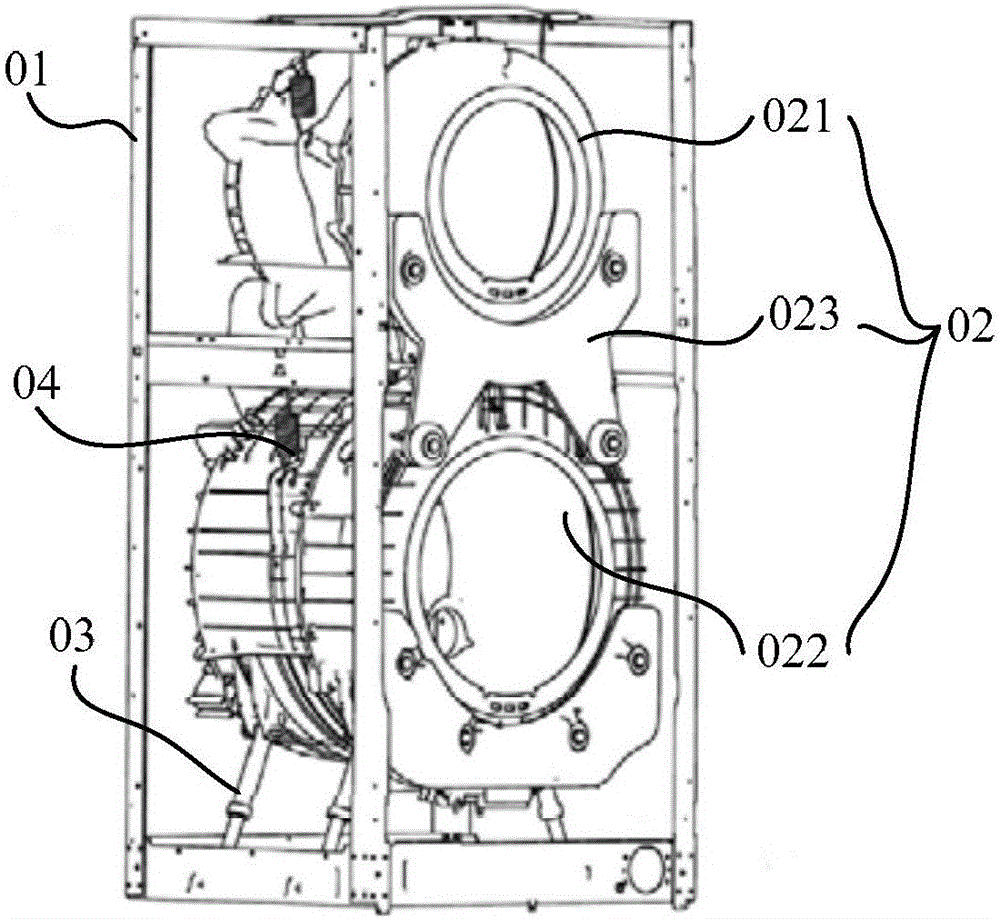

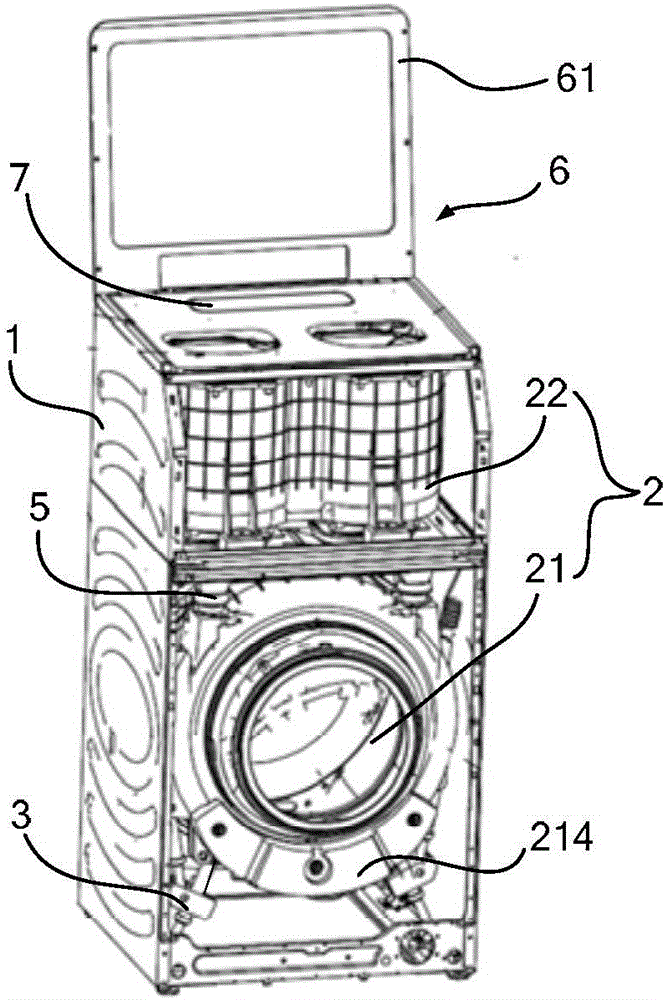

[0046] Such as image 3 , Figure 4 and Figure 5 As shown, in this embodiment, the two upper washing tubs 22 are all set as pulsator-type washing tubs, so that the three-tube washing machine can take into account the advantages of the pulsator-type washing machine, saving electricity and time, and being able to add clothes at any time. The drum type washing machine has the advantages of saving water, less wear and tear, and high cleanliness. It is more convenient for users to choose which washing drum to use according to the type of clothes, washing requirements and other conditions.

[0047]Since two upper washing tubs 22 are arranged above the lower washing tub 21, this structure causes the overall center of gravity of the washing tub assembly 2 to be higher. Therefore, during the working process, the local vibration above the two upper washing drums 22 is relatively large, and it is easy to collide with the casing 1 . Therefore, the washing tub assembly 2 is preferably ...

Embodiment 2

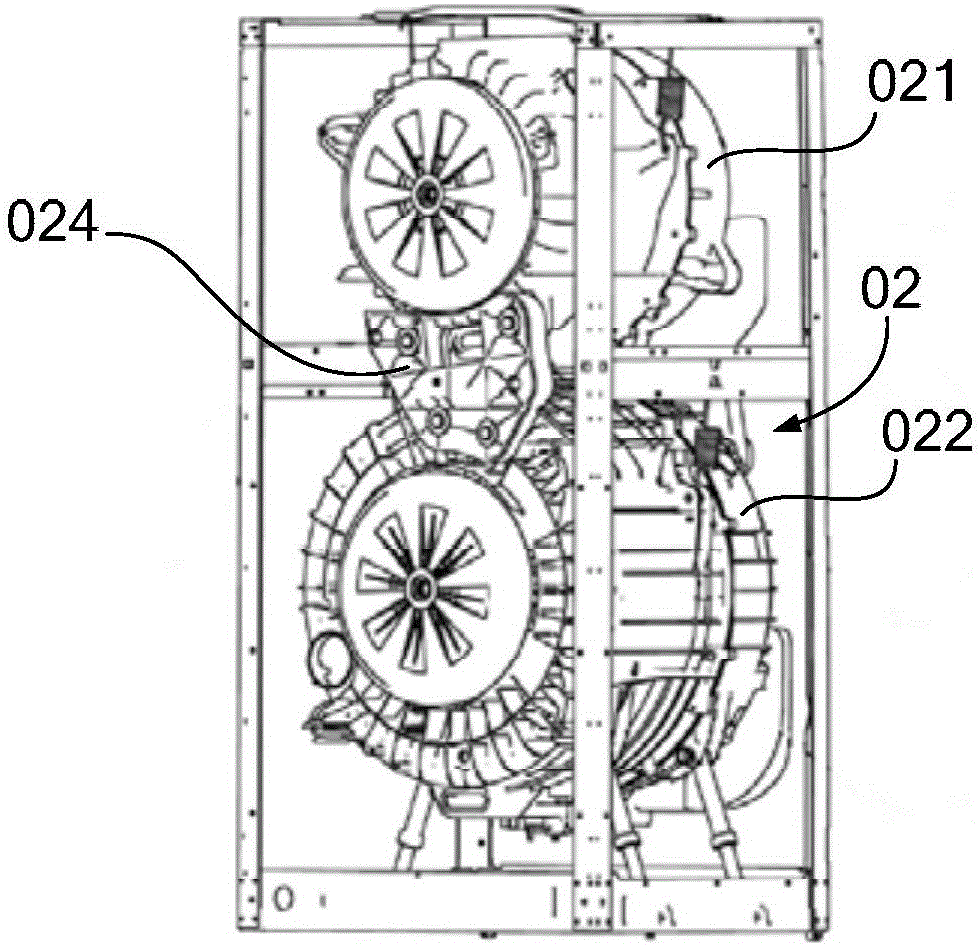

[0116] see Figure 25 , Figure 26 and Figure 27 , the difference between the three-barrel washing machine provided in this embodiment and Embodiment 1 is that: the two upper washing drums 22 are all configured as drum-type washing drums, and the two upper drums are arranged side by side, respectively located on the left and right sides, so that better utilization The horizontal space of the cabinet of the three-tub washing machine. In addition, compared with the scheme in which the upper washing tub 22 is a pulsator-type washing tub, since the openings of the two drum-type washing tubs face forward, the body height of the three-tub washing machine is relatively lower, which is suitable for shorter users. It will be more convenient when using two upper washing tubs 22.

[0117] see Figure 27 In this embodiment, since the motors driving the two upper washing drums 22 to rotate are installed behind the upper washing drum 22 and the rear motors 221 of the two upper washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com