Nickel-based alloy electrolytic polishing liquid and polishing method thereof

A nickel-based alloy, electrolytic polishing technology, applied in the field of electrolytic polishing, can solve the problems of fixed size, inability to determine the composition, inability to obtain an ideal polished surface, etc., to achieve obvious metallic luster, improve corrosion resistance, and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The electrolytic polishing process for the nickel-based alloy sealing plate of the nuclear power core make-up water tank, the specific steps are as follows:

[0045] (1) Carry out activation pretreatment to nickel-based alloy electrolytic polishing workpiece, guarantee that there is no excess water on the surface of the workpiece; the pretreatment is to remove surface oil stains from the workpiece with lye, and then put the cleaned workpiece into a concentration of hydrogen peroxide 2 % of 5% dilute nitric acid into the activation for 10 minutes, rinse with tap water after activation, and put it into the electrolytic cell after there is no obvious water flow on the surface of the workpiece.

[0046] (2) The composition of the electrolyte in the electrolytic cell is (by weight percentage): concentration is 85wt% phosphoric acid 65%, 98wt% sulfuric acid 12%, ammonium thiocyanate 4%, 1,4-butynediol 7%, dimethylglyoxime 6%, polyethylene glycol (M=400) 3%, guar gum 3%.

[0...

Embodiment 2~4

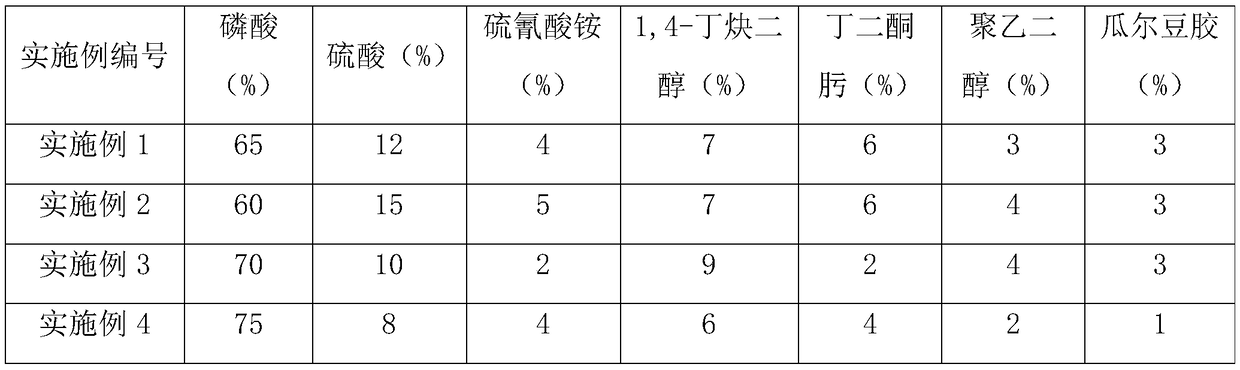

[0050] Using the raw materials and methods of Example 1, the only difference is that the composition of the electrolyte in the electrolytic cell is different. The composition of the electrolyte is shown in Table 1. Other process and processing parameter are identical with embodiment 1. Wherein, the concentration of nitric acid is 85wt%, and the concentration of sulfuric acid is 98wt%.

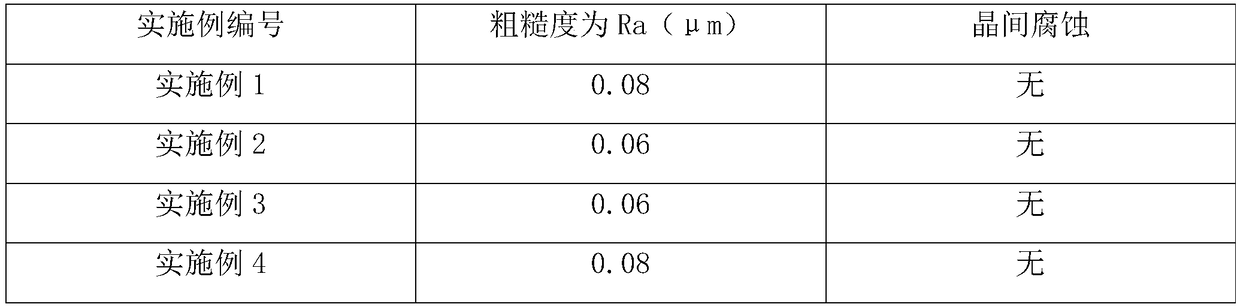

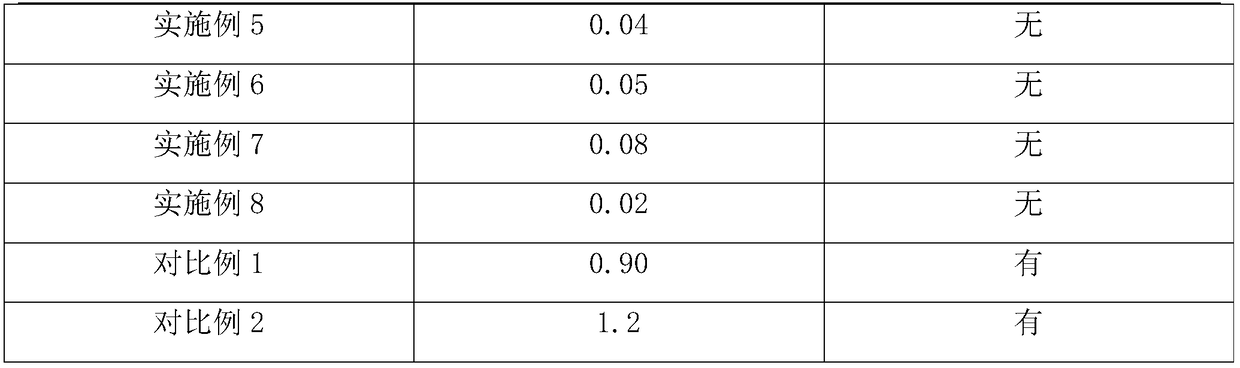

[0051] The roughness and metallographic inspection results of the polished workpiece are shown in Table 3.

[0052] The electrolyte composition that adopts in the embodiment 1~4 of table 1

[0053]

Embodiment 5~8

[0055] Using the raw materials and methods of Example 1, the only difference is that the process parameters are different during electrolysis. The detailed process parameters are shown in Table 2. The roughness and metallographic inspection results of the polished workpiece are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com