Anode stabilizing device of IGZO film formation equipment

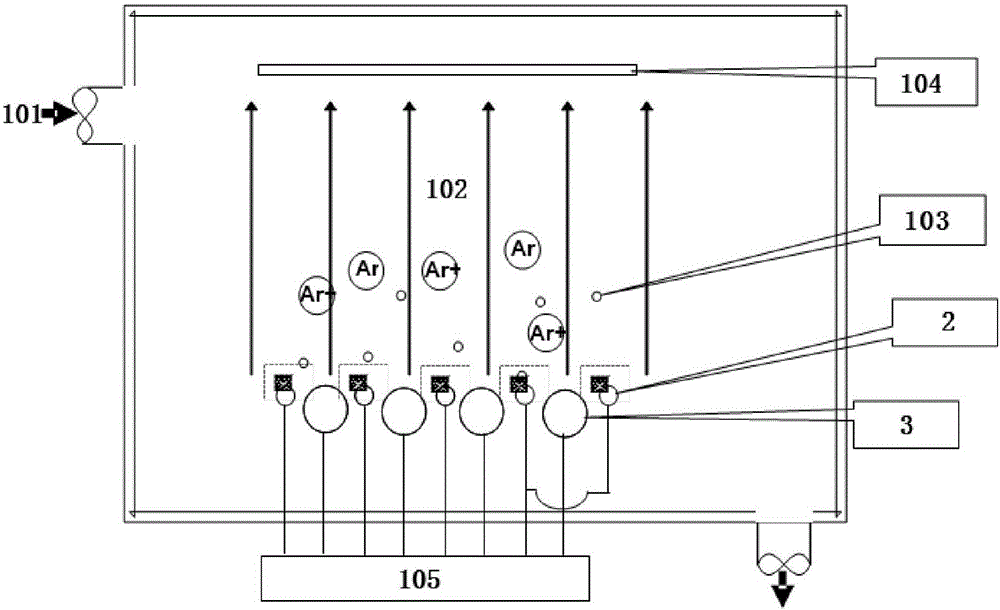

A technology for anode stabilization and film-forming equipment, which is applied in metal material coating process, vacuum evaporation coating, coating, etc., and can solve the problems of burning of the aluminum spray layer on the anode surface, ineffective export of electrons, and increase of current at the bottom of the anode and other problems, to avoid the deposition of IGZO insulating film, improve the utilization rate of equipment, and achieve the effect of uniform electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

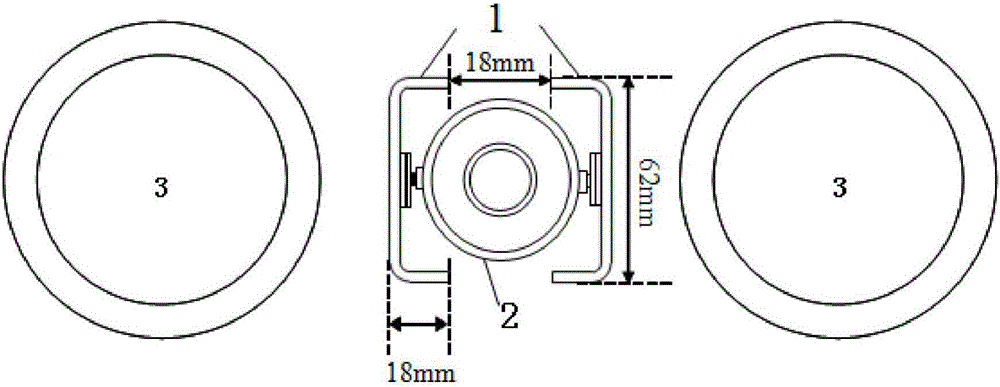

[0024] Embodiment 1: as Figure 2~3 The anode stabilizing device of the IGZO film forming equipment shown includes two isolation assemblies 1. The cross sections of the isolation assemblies 1 are both C-shaped, and the length of the C-shape is 62 mm and the width is 18 mm. The two isolation assemblies 1 are facing each other, and are fixed and surrounded by an insulating block around the anode 2 to protect the anode 2 in the inner space formed by the isolation assembly 1, and the two targets 3 are respectively located on both sides of the isolation assembly 1, so that The C-shaped structure is isolated and arranged between the anode 2 and the target 3 . The isolation assembly 1 is arranged in five sections along the axial direction of the anode 2, and the length of each section is 575 mm. The bottom end of the isolation assembly 1 completely covers the bottom end 4 of the anode 2, and the top is 32 mm lower than the top of the anode 2 and higher than the target. 3 230mm. The...

Embodiment 2

[0026] Embodiment 2: The structure of the isolation assembly 1 is roughly the same as that of the embodiment 1, the difference is that on the isolation assembly 1, an aperture for supplying electrons to lead out the anode 2 is evenly opened, and the aperture of the aperture is 12mm, and the isolation assembly 1 port The distance between is reduced to 9mm, such as Figure 4~5 shown. In this embodiment, the electron exporting channel of the anode 2 is wide and uniform, so that the distribution of the plasma is more uniform, the electrons are exported in time, and the film forming rate can be further stabilized.

Embodiment 3

[0027] Embodiment 3: The anode stabilization device in this embodiment is an isolation assembly 1 with an arc-shaped section, such as Figure 6~7 As shown, the spacer assembly 1 is arranged directly in front of the anode 2, with a distance of 9.5 mm from the anode, while two targets 3 are located on both sides of the anode 2, and the distance between the two ends of the spacer assembly 1 and the target 3 is 12 mm. In this embodiment, the isolation component 1 is arranged in an arc shape, in addition to effectively widening the channel for electrons to be exported to the anode 2, so that the plasma distribution is more uniform; the electrons are exported in time to stabilize the film formation rate. In addition, when the thickness of the insulating film increases, it is not easy to cause the film layer to fall off, which will affect the environment of the chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com