Thermoanaerobacterium thermosaccharolyticum and application thereof to biological hydrogen production

A technology of saccharoanaerobic bacteria and biological hydrogen production, which is applied in the field of thermophilic saccharolytic anaerobic bacteria and its application in biological hydrogen production, can solve the problems of acid pretreatment liquid environmental pollution and high hydrogen production efficiency, and achieve the goal of producing Excellent hydrogen efficiency, broad application and promotion prospects, and the effect of efficient hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

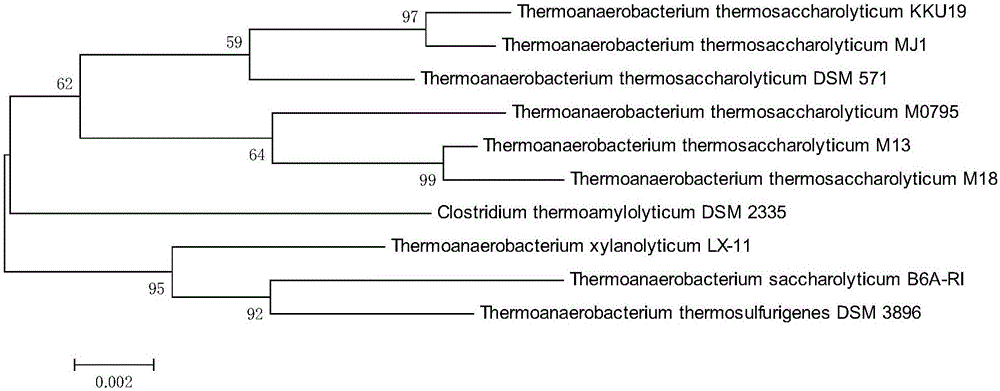

[0056] Example 1: Isolation and identification of thermophilic saccharolytic anaerobic bacteria:

[0057] (1) Acquisition of unknown bacterium stable culture medium: the papermaking sludge (from a paper mill in Guangdong Province) that will be taken is made into 10% (w / v) with sterile 50mM phosphate buffer in the ultra-clean workbench The suspension was inoculated in the xylose liquid medium whose carbon source was 5g / L xylose at a ratio of 10% (v / v), placed in a shaker at 55°C for 120h, and then cultured with 10% (v / v) The proportion of v) was inoculated in the xylose liquid medium whose carbon source was 5g / L xylose in fresh carbon source, continued to cultivate for 72h, and repeated transfer culture 10 times, in order to obtain stable flora distribution, wherein, the xylose liquid medium The main ingredients are: xylose 5g / L (carbon source), ammonium chloride 1g / L, sodium chloride 1g / L, dipotassium hydrogen phosphate 1g / L, potassium dihydrogen phosphate 1g / L, cysteine 0.5...

Embodiment 2

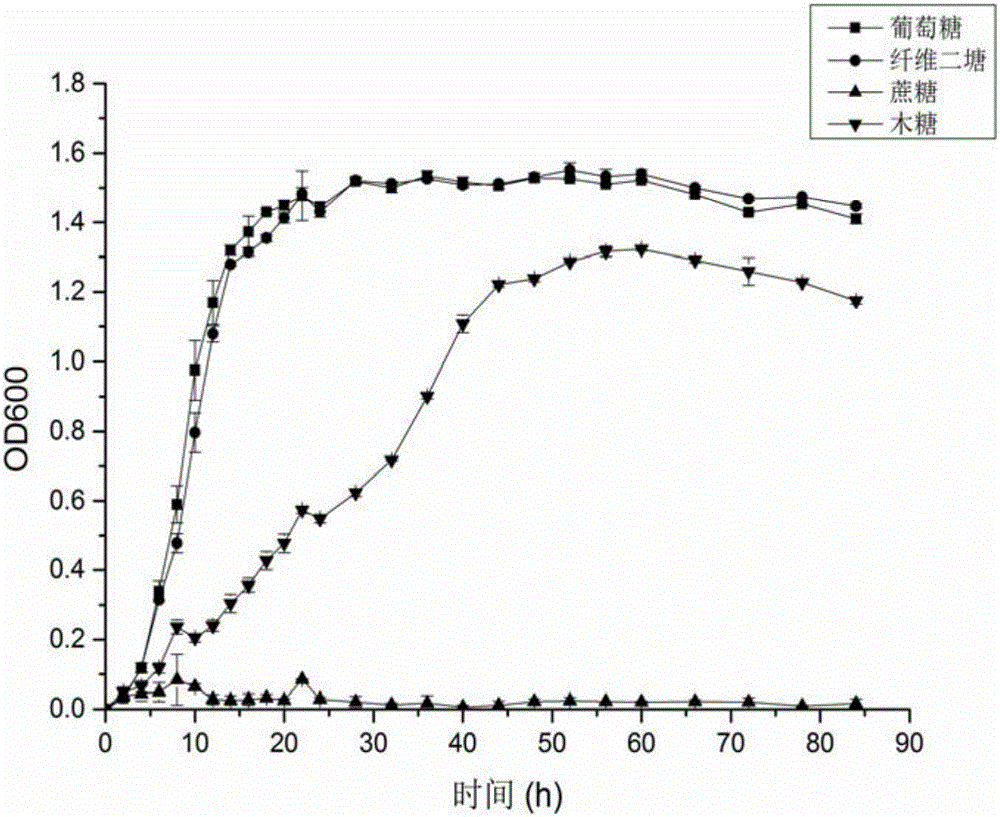

[0070]Example 2: Determination of the ability of thermophilic saccharolytica anaerobic bacteria to produce hydrogen with different carbon sources

[0071] (1) Preparation of thermophilic anaerobic saccharolyticum seed solution: the culture solution of the isolated single colony obtained in step (4) of Example 1 was first passed through a 10mL cillin bottle (4.5mL seed medium was housed) at 55 ℃, 150rpm shaking culture for 18h to activate, and then in a 100ml serum bottle (with 45mL seed medium) at 55°C, 150rpm shaking culture for 18h for amplification to obtain seed liquid, wherein the seed medium is 5g / L xylose Culture medium (with the xylose medium in embodiment 1).

[0072] (2) Preparation and sterilization of fermentation media with different carbon sources: the fermentation media uses three carbon sources, namely 5g / L glucose, 5g / L cellobiose and 5g / L xylose, and other components except carbon sources The same as the above seed medium, put 27ml of fermentation medium int...

Embodiment 3

[0074] Example 3: Determination of Hydrogen Production Ability of Thermosaccharolyticum Anaerobic Bacteria with Different Concentrations of Xylose

[0075] (1) The preparation of the seed solution is the same as in Example 2.

[0076] (2) The preparation and sterilization of the fermentation medium were the same as in Example 2, except that the carbon sources of the fermentation medium were 2.5 g / L, 5 g / L, 7.5 g / L and 10 g / L of xylose respectively.

[0077] (3) The fermentative hydrogen production by thermophilic saccharolytic anaerobic bacteria is the same as in Example 2, and the results are as follows Figure 5 As shown, the yields of hydrogen after the fermentation are: 39.64mM, 71.57mM, 71.25mM, 60.38mM respectively, and the molar hydrogen yields converted into substrates are: 2.38mol, 2.15mol, 1.43mol and 0.91mol respectively, indicating that the separation The hydrogen production efficiency of the thermophilic saccharolytica anaerobic bacteria decreased with the increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com