Melting and purifying method for acquiring high purity NaCl crystal grains

A purification method and high-purity technology, which is applied in the field of high-purity NaCl material production, can solve problems such as failure to meet purity requirements and environmental protection pressure, and achieve considerable economic and social benefits, low production energy consumption, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

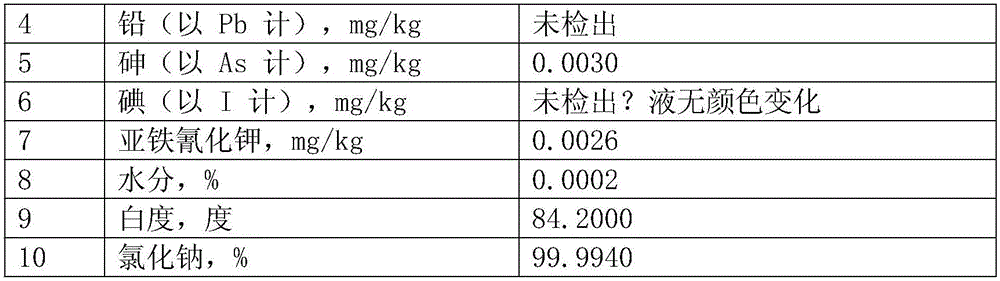

Examples

specific Embodiment approach

[0017] 1) Take 10kg of coarse-grained salt, put it into 99 porcelain alumina and move it into a high-temperature furnace;

[0018] 2) The temperature of the furnace rises to 780°C within 30 minutes, and after constant temperature for 2 hours, the temperature is naturally lowered to 500°C and kept constant for 0.5 hours, then within 20 minutes, the temperature is raised from 500°C to 780°C, and kept constant for 0.5 hours;

[0019] 3) After continuing to heat up to 1000°C, immediately stop heating and naturally cool down to 780°C, and then raise the temperature to 1000°C within 20 minutes. This process was repeated 2 times.

[0020] 4) Rapidly raise the temperature from 1000°C to 1450°C, keep the temperature constant for 5 minutes, then cool down naturally to 900°C, and then raise the temperature to 1450°C for 5 minutes. Repeat the process 2 times;

[0021] 5) Rapidly increase the temperature from 1450°C to 1700°C, immediately cool down to 900°C naturally, and then rapidly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com