Scraper conveying sieving machine

A technology for conveying screens and scrapers, which is applied in conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of high input manpower, low utilization rate, and large screening volume, so as to increase screening volume and reduce production costs. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

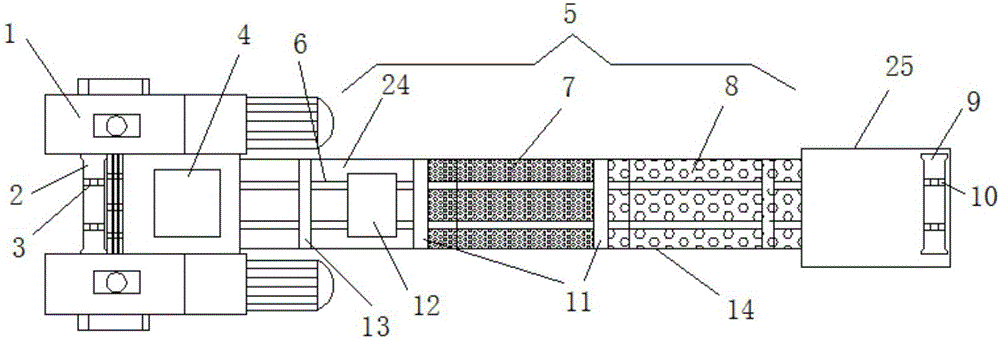

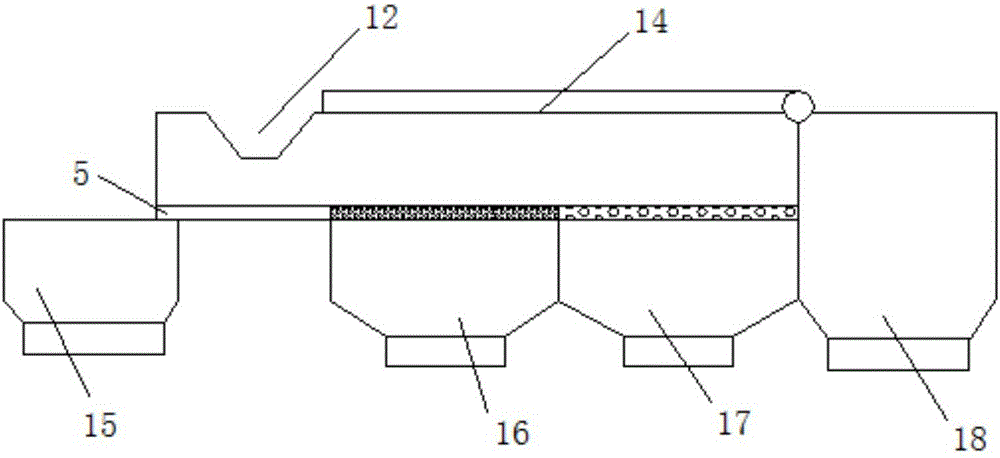

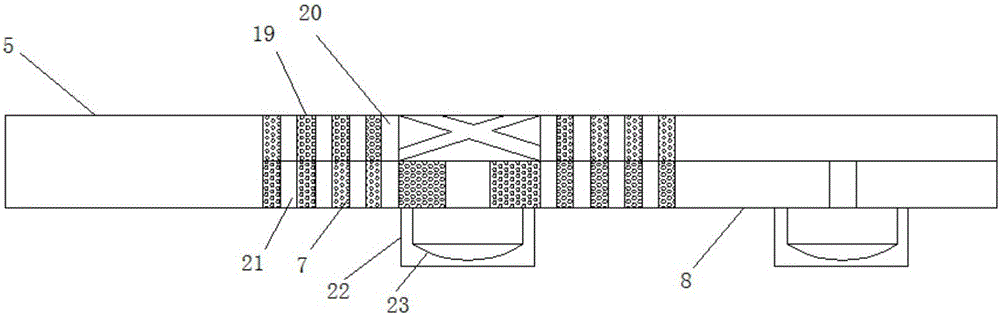

[0020] refer to Figure 1-4 , the present invention provides a scraper conveying screening machine, comprising a housing 14, the left and right ends of the housing 14 are respectively equipped with a machine head 1 and a machine tail 25, and the middle of the inner cavity of the machine head 1 and the machine tail 25 is respectively provided with a front outlet Material port 15 and rear discharge port 18, the middle part of machine head 1 is provided with head wheel fixed mount 2, and the middle part of head wheel fixed mount 2 is connected with head wheel 3 by rotating shaft, and the middle part of machine tail 25 is provided with tail wheel fixed mount 9, The middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com