Full-automatic lid and tray type opening, packing and sealing integrated machine

A world cover and all-in-one machine technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve problems such as poor stability, troublesome switching of different models and specifications, manual adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

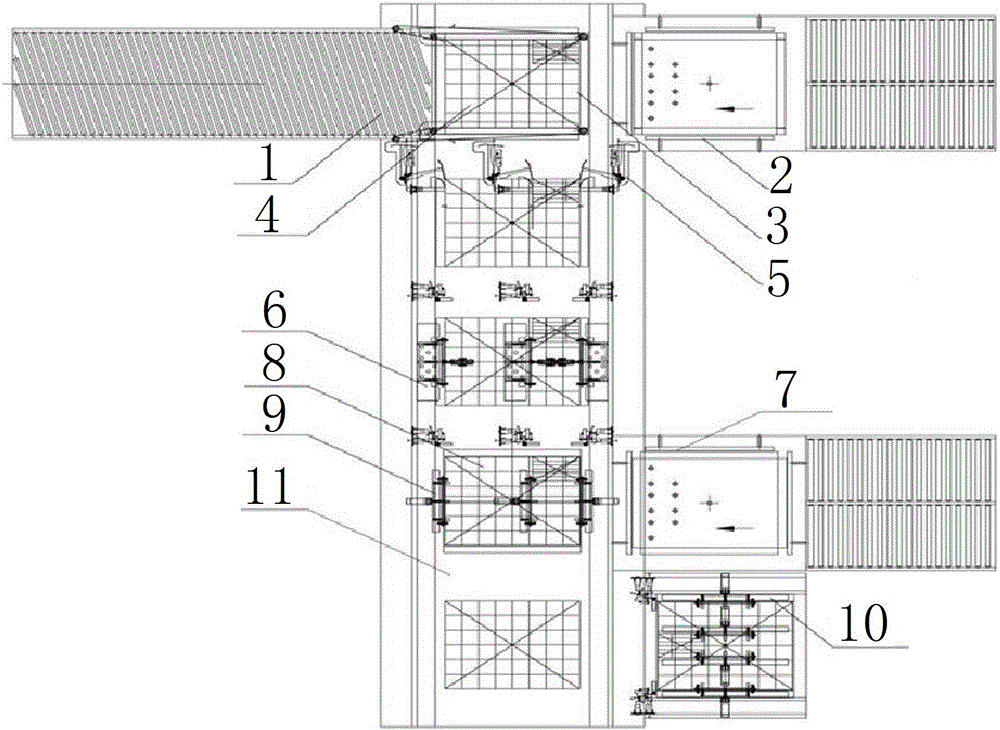

[0011] Such as figure 1 As shown in the figure, the full-automatic all-in-one machine for unpacking, opening, packing and sealing includes product automatic positioning mechanism 1, ground cover silo 2, ground cover automatic positioning mechanism 3, press box long side forming mechanism 4, and end small cover automatic folding mechanism 5. Short-side folding mechanism 6, canopy hopper 7, canopy automatic positioning mechanism 8, canopy short-side folding mechanism 9, canopy long-side folding mechanism 10, complete machine conveying mechanism 11, product automatic positioning mechanism 1. The long side forming mechanism 4 of the pressure box, the automatic positioning mechanism 3 of the ground cover and the silo 2 of the ground cover are successively arranged on the horizontal station, and the automatic folding mechanism 5 of the end small cover is set at the lower part of the hopper 7 of the ground cover. Box long side forming mechanism 4, short side turning mechanism 6 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com