Automobile hub clamping fixture with automatic centering function

An automobile hub and automatic centering technology, applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of rising product failure rate, sluggish work efficiency, poor positioning accuracy, etc., to improve positioning and clamping accuracy, Improve work efficiency and improve the effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

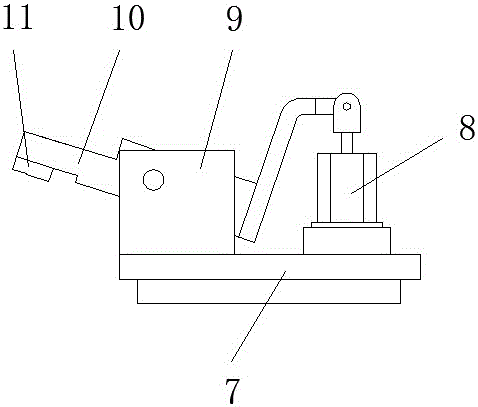

[0020] A kind of automobile hub clamping tool with automatic centering function described in the present invention, such as figure 1 , figure 2 As shown, it includes: a body 1 and a rotary table 2 arranged above the body 1; the body 1 is provided with a PLC control unit and an electric control unit that drives the rotary table 2 to rotate; the center of the rotary table 2 A pneumatic expansion shaft 3 is fixed; the pneumatic expansion shaft 3 is provided with pneumatic pressure blocks 4 uniformly distributed in the circumferential direction; the upper surface of the rotary table 2 is provided with positioning grooves 5 uniformly distributed in the radial direction; the positioning grooves 5 is provided with pressing module 6, such as image 3 As shown, the compression module 6 includes: a bottom plate 7 and a compression cylinder 8 and a bracket 9 arranged on the bottom plate 7; the compression cylinder 8 and the bracket 9 are aligned and arranged side by side; the bracket 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com