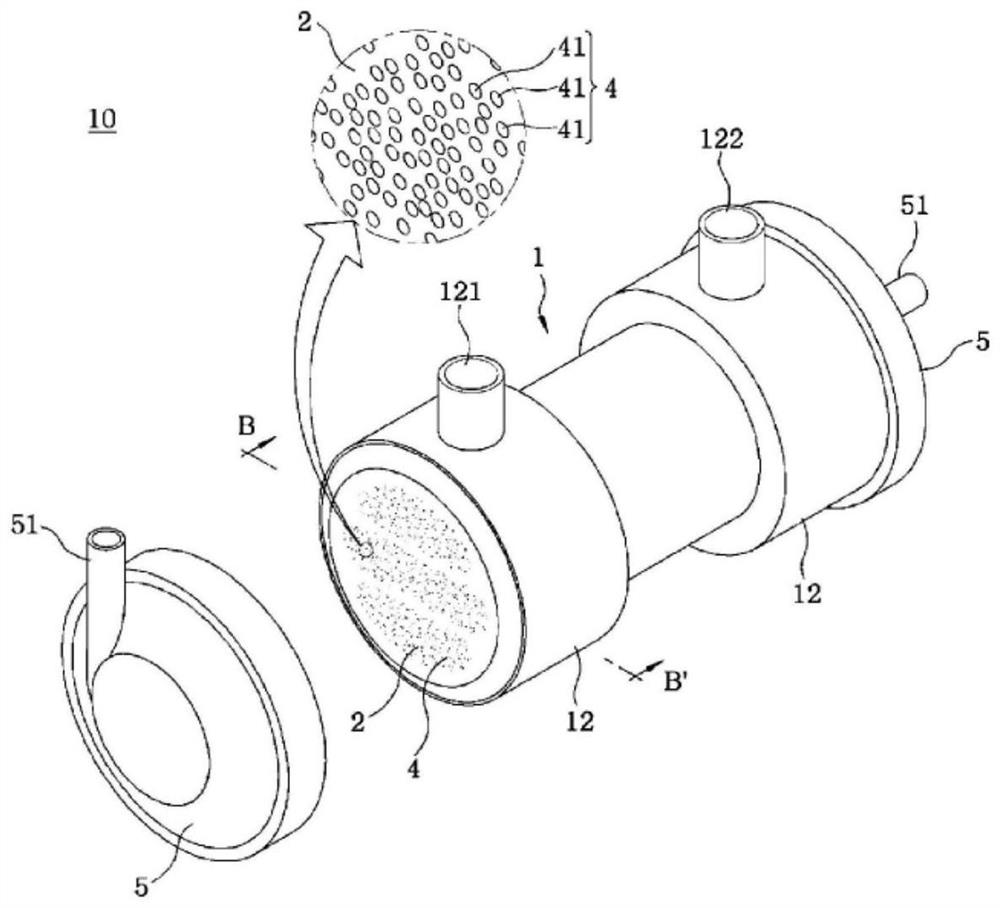

A detachable hollow fiber membrane module and its assembly method

A fiber membrane and hollow technology, which is applied in the field of detachable hollow fiber membrane module structure, can solve the problems of waste of material, lack of rigidity, labor-hours, etc., and achieves the effect of simple assembly and easy replacement of membrane filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

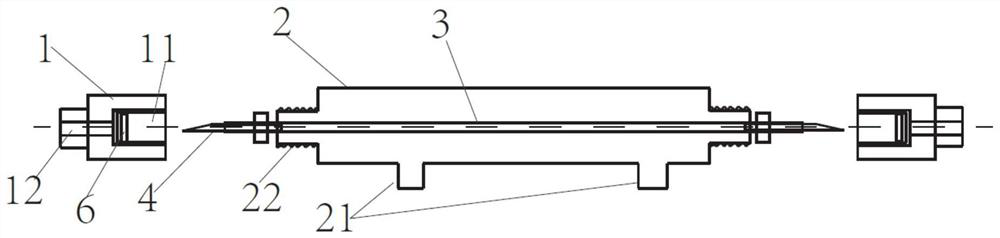

Embodiment 1

[0041] Such as figure 2 Shown is a schematic diagram of the detachable hollow fiber membrane module structure of Example 1 of the present invention, which is a monofilament membrane module structure, which is usually used in laboratories to test the filtration performance of a certain hollow fiber membrane , and various working parameters such as osmotic pressure and backwash time. Membrane shell 2 comprises two water production ports, is located at a hollow fiber membrane membrane silk 3 inside membrane shell 2, has through hole in the middle of this hollow fiber membrane membrane silk 3, and its length is greater than the length of described membrane shell 2, makes hollow The fiber membrane filaments 3 can protrude to the outside of the membrane shell 2; the two ends of the membrane shell 2 are also provided with end caps 1 . The hollow fiber membrane filament 3 is provided with a needle 4, about 1 / 2 of the length of the needle 4 is inserted into the through hole of the me...

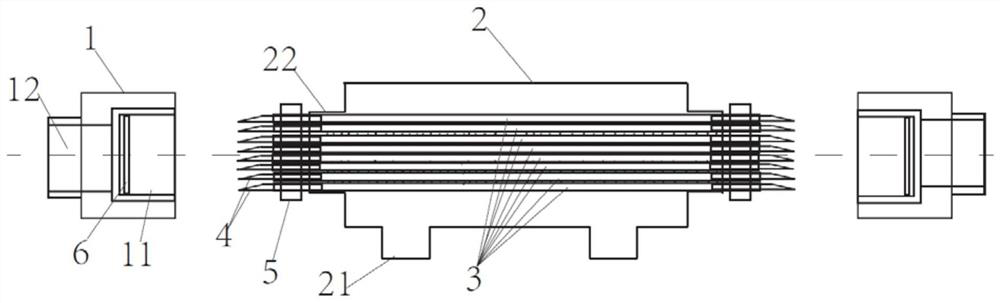

Embodiment 2

[0047] image 3 It is a schematic structural diagram of a detachable hollow fiber membrane module in Example 2 of the present invention. The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the hollow fiber membrane filaments 3 contained in the membrane case 2 are not single, but multiple. For the membrane module that needs to assemble a plurality of membrane filaments 3, the membrane assembly structure is basically the same as that of Example 1, except that before inserting the hollow fiber membrane filaments 3 into the module 2, there is another step of aligning the membrane filaments: A plurality of hollow fiber membrane filaments 3 are arranged side by side to form a membrane bundle. The cross-section of the membrane bundle is preferably the same as the shape of the port of the membrane shell 2, and then the membrane bundle is inserted into the membrane shell 2, and the two ends of the membrane bundle exposed outside the membrane shell 2. Then, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com