Combined type cake mold with anti-bubble function

A cake mold and combined technology, which is applied in household utensils, kitchen utensils, food science, etc., can solve the problems of air bubbles in mold slurry, cake quality, and adverse effects caused by air bubbles, and achieve cost saving, simple operation, and waste of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

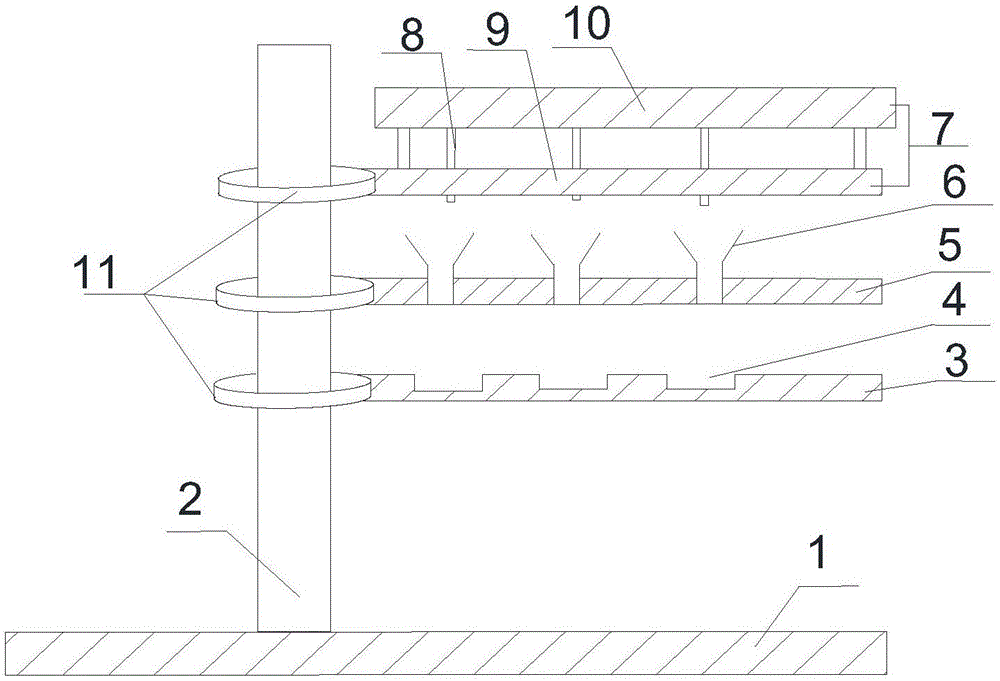

[0022] Such as figure 1 As shown, a combined cake mold with anti-bubble function of the present invention includes a base 1, a support rod 2 is vertically connected above the base 1, and an injection molder is connected to the support rod 2, and the injection mold The device includes a template 3 connected to the support rod 2, a plurality of mold bases 4 are arranged on the template 3, and an injection plate 5 is arranged on the top of the template 3, and the injection plate 5 is connected with the support rod 2, and the injection plate 5 is provided with The injection funnel 6 connected to the mold base 4 in one-to-one correspondence, the injection funnel 6 is located directly above the mold base 4, a stirring plate 7 is arranged above the injection plate 5, and the stirring plate 7 is movably connected with the support rod 2, Stirring rods 8 corresponding to the mold bases 4 are arranged on the stirring plate 7 . The injection funnel 6 is movably connected with the injecti...

Embodiment 2

[0025] Based on Embodiment 1, the stirring plate 7 includes a protective plate 9 connected and fixed to the support rod 2, a needle plate 10 is connected above the protective plate 9, and stirring rods corresponding to the mold base 4 are arranged on the needle plate 10. 8. The protective plate 9 is provided with a small hole for the stirring rod 8 to pass through, and the protective plate 9 and the needle plate 10 are connected by telescopic columns. When the stirring rod is not needed, move the needle plate on which the stirring rod is installed, and the telescopic column is used to adjust the height of the needle plate. After the needle plate moves upward, the stirring rod on the needle plate will be hidden in the small hole of the protection plate. Avoid contamination of the stirring rod or injury to the operator by the tip of the stirring rod.

Embodiment 3

[0027] Based on the above embodiment, the protective plate 9 , the template 3 , the injection plate 5 and the support rod 2 are respectively movably connected through the turntable 11 . The protective plate, template and injection plate can be rotated around the support rod through the turntable, which is convenient for adjusting the relative positions of the protection plate, template and injection plate at any time during the cake injection molding operation. After the grouting is completed, the injection plate can be rotated away , so that the stirring rod passing through the protective plate can quickly reach the corresponding stirring position, and the movement of the stirring rod is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com