Method for analysis of oil product monocyclic aromatic hydrocarbon

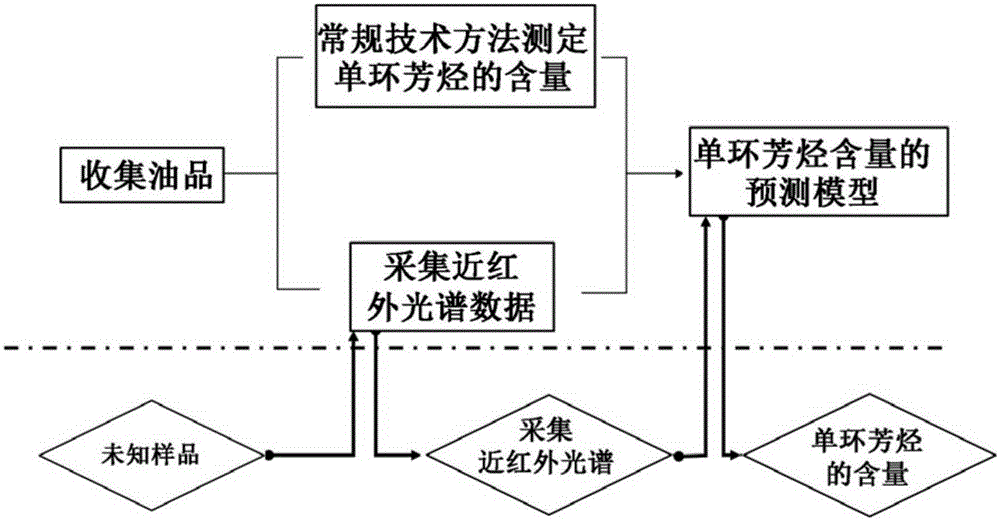

A technology for single-ring aromatics and oil products, which is applied in the field of near-infrared analysis of single-ring aromatics in oil products, can solve the problems of long analysis period, etc., and achieve the effect of simple method, easy implementation, and low investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

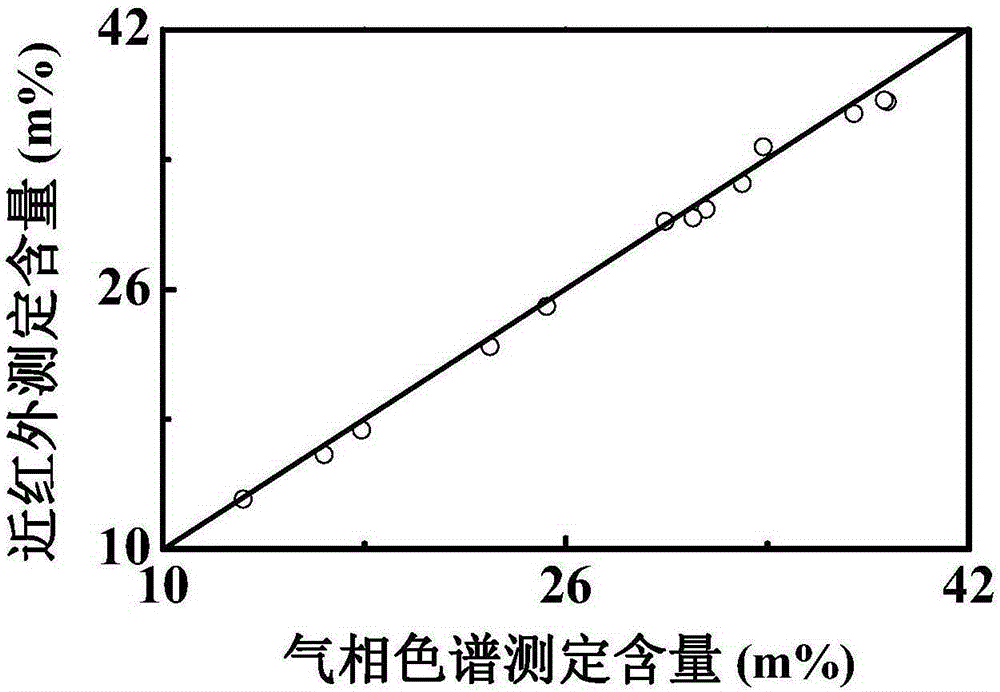

[0033] Near-infrared analysis method for single-ring aromatics in light oil products:

[0034] 1) Collect samples: collect naphtha, top oil, raffinate, and aviation kerosene; measure the content of single-ring aromatics by gas chromatography, and obtain the mass percentage data of C6 aromatics (m%) and C7 aromatics mass percentage data (m%), mass percentage data of C8 aromatics (m%), mass percentage data of C9 aromatics (m%), mass percentage data of C10 aromatics (m%).

[0035] 2) Collection of spectra: The near-infrared spectrum of the sample was collected by the Antaris II Fourier near-infrared spectrometer of American Thermo-Fisher Company with a transmission sampling module; the collection range was 12000-4000cm -1 , scan 32 times to get the average spectrum, and scan the background before each sample experiment; the spectrum is collected using a 6mm sample tube.

[0036] Preparation of the near-infrared spectrometer: when starting up, turn on the power of the near-infrar...

Embodiment 2

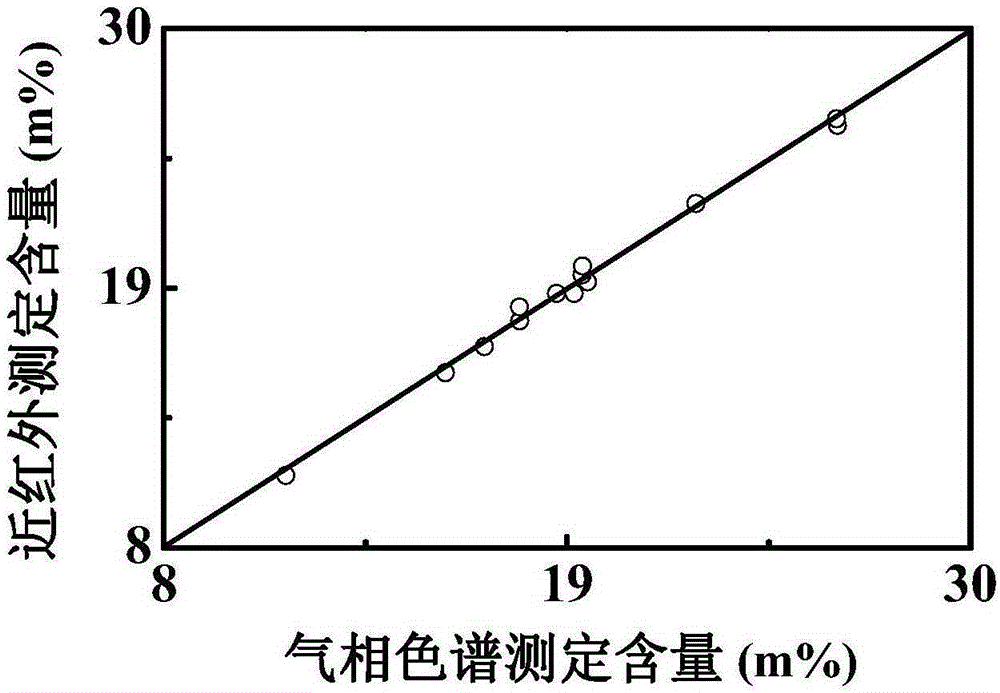

[0042] Near-infrared analysis method for single-ring aromatics in light oil cracking liquid phase oil:

[0043]1) Collect samples: collect naphtha and tops oil cracking liquid phase oil products; measure the content of single-ring aromatics by gas chromatography, and obtain the mass percentage data of C6 aromatics (m%) and C7 aromatics mass percentage data (m%) %), mass percent data of C8 aromatics (m%), mass percent data of C9 aromatics (m%), mass percent data of C10 aromatics (m%).

[0044] 2) Collection of spectra: The near-infrared spectrum of the sample was collected by the Antaris II Fourier near-infrared spectrometer of American Thermo-Fisher Company with a transmission sampling module; the collection range was 12000-4000cm -1 , scan 32 times to get the average spectrum, and scan the background before each sample experiment; the spectrum is collected using a 1mm cuvette.

[0045] Preparation of the near-infrared spectrometer: when starting up, turn on the power of the ...

Embodiment 3

[0052] Near-infrared analysis method for single-ring aromatics in heavy oil pyrolysis liquid phase oil:

[0053] 1) Collect samples: collect hydrogenated tail oil cracking liquid phase oil; measure its single-ring aromatics content by gas chromatography, and obtain C6 aromatics mass percentage data (m%), C7 aromatics mass percentage data (m%), The mass percentage data of C8 aromatics (m%), the mass percentage data of C9 aromatics (m%), and the mass percentage data of C10 aromatics (m%).

[0054] 2) Collection of spectra: The near-infrared spectrum of the sample was collected by the Antaris II Fourier near-infrared spectrometer of American Thermo-Fisher Company with a transmission sampling module; the collection range was 12000-4000cm -1 , scan 32 times to get the average spectrum, and scan the background before each sample experiment; the spectrum is collected using a 6mm sample tube.

[0055] Preparation of the near-infrared spectrometer: when starting up, turn on the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com