Catalyst for preparing arene from synthesis gas and use method of catalyst

A synthesis gas and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low yield of aromatics, increase the yield of aromatics, reduce production costs, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] After weighing 539 grams of ferric nitrate, 182.5 grams of manganese nitrate (50%), 11.7 grams of lanthanum nitrate and 500 grams of water, mix them uniformly, precipitate with 500 grams of concentrated ammonia water (25%), and after aging for 12 hours at room temperature, wash , centrifuged, dried at 120°C for 8 hours, and calcined at 550°C for 6 hours to obtain Fe-Mn oxide solid. Weigh 72.1 g Fe-Mn oxide solid, impregnate 42 g containing 0.53 g K 2 CO 3 Aqueous solution, dried at 120°C for 6 hours, calcined at 500°C for 4 hours to obtain Fe composite component F-1.

[0036] Weigh 60 grams of ZSM-5 molecular sieves (the molar ratio of silicon oxide to aluminum oxide is 400), impregnate with 116 grams of aqueous solution containing 36.7 grams of zinc nitrate and 16.2 grams of phosphoric acid (85%), and after aging for 4 hours at room temperature MZ1 was obtained by drying at 120°C for 8 hours and calcining at 600°C for 6 hours.

[0037] Weigh 40 grams of F-1, 40 gram...

Embodiment 2-7

[0040] F2-F9 were prepared by the same method as in Example 1, and their compositions are listed in Table 1.

[0041] Catalysts b to i were prepared by the same method as in Embodiment 1, and the evaluation method was the same as in Embodiment 1.

[0042] Catalyst components and evaluation results are listed in Table 2 and Table 3, respectively.

Embodiment 8-11

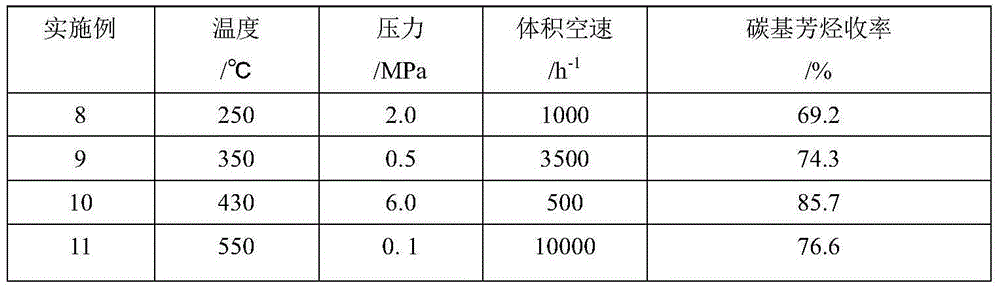

[0050] Using catalyst e, the evaluation conditions and evaluation results are shown in Table 4.

[0051] Table 1

[0052] Fe composite oxide Weight composition (wt%) F-1 74.7Fe: 20Mn: 0.3K: 5.0La F-2 50Fe: 25Mn: 5Na: 10La F-3 39.9Fe: 50Mn: 10Mg: 0.1La F-4 58.5Fe: 35Mn: 4.0K: 2.5.0Ce

[0053] F-5 55.3Fe: 35.2Mn: 5.2Ca: 4.3Zn F-6 50.4Fe: 38.7Mn: 6.0K: 2.0Ce: 2.9Si F-7 65Fe: 25Mn: 4.8K: 2.0La: 2.2Ce: 1.0Ga F11 50.4Fe: 38.7Mn: 6.0K: 2.9Si (weight ratio) F12 65Fe: 25Mn: 4.8K: 1.0Ga (weight ratio)

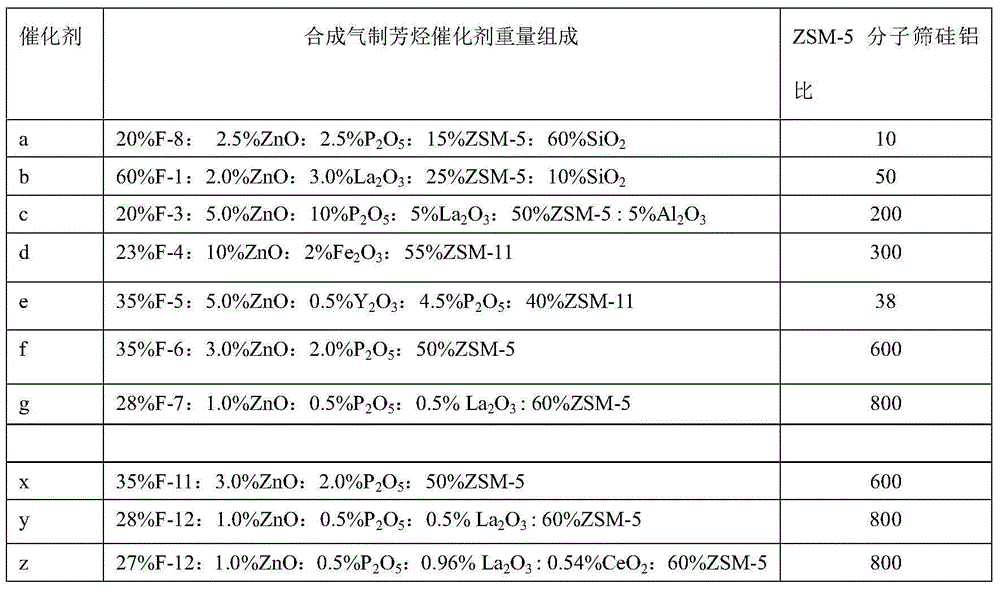

[0054] Table 2

[0055]

[0056] table 3

[0057] Example catalyst Aromatics yield / % 1 a 69.7 2 b 72.3 3 c 71.0 4 d 70.2 5 e 79.2 6 f 59.7 7 g 56.8 8 h 63.2 9 i 57.6 comparative example 1 x 54.2 2 y 50.3 3 z 49.5

[0058] Table 4

[0059]

[0060] Table 4 (Continued from previous table)

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com