Horizontal servo electric control cabinet element layout system

A servo electric and component technology, applied in the field of component layout system, can solve the problem of large size in height direction, achieve good electrical contact performance, improve electromagnetic compatibility, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

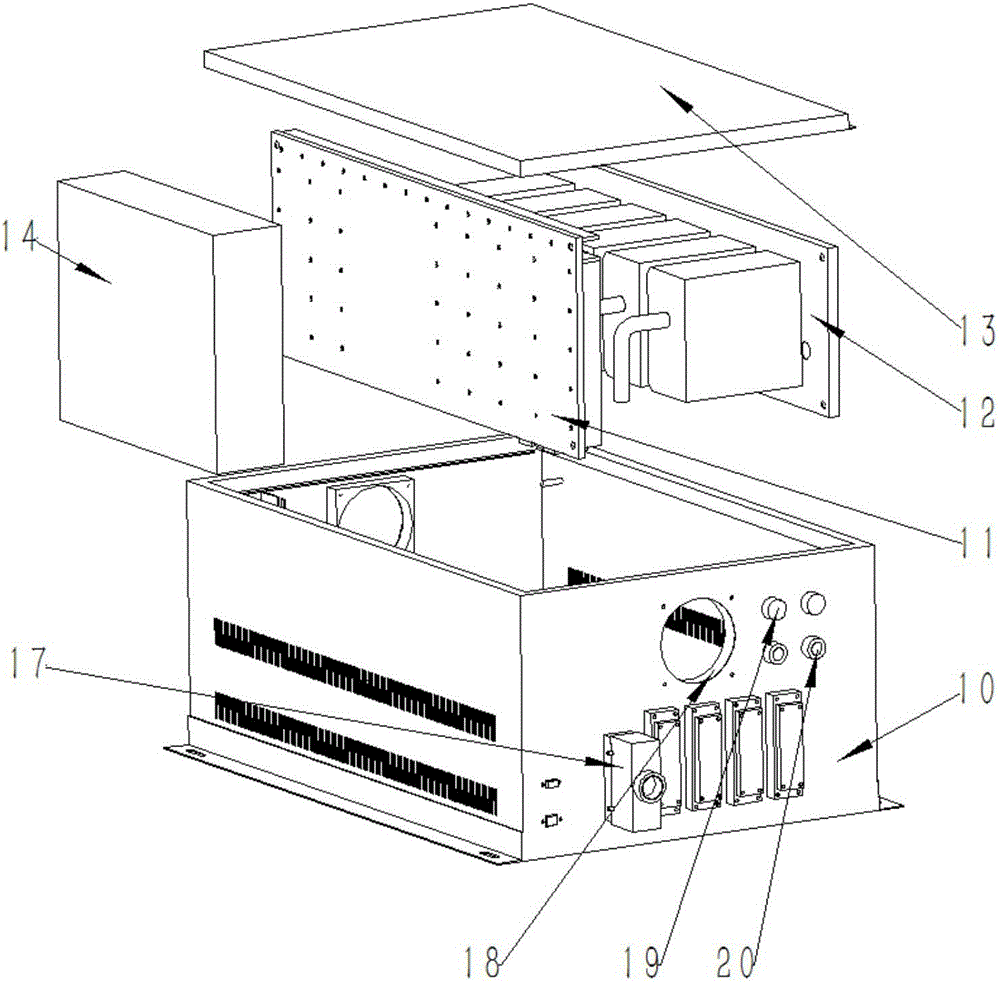

[0032] Such as figure 1 , the component layout system of the horizontal servo electric control cabinet in this preferred embodiment, the electric control cabinet 10 includes a cabinet body 100, a component mounting plate 11, a driver mounting plate 12, and a cabinet door 14, and various components are installed on the electric control cabinet according to rules. Cabinet 10 interior.

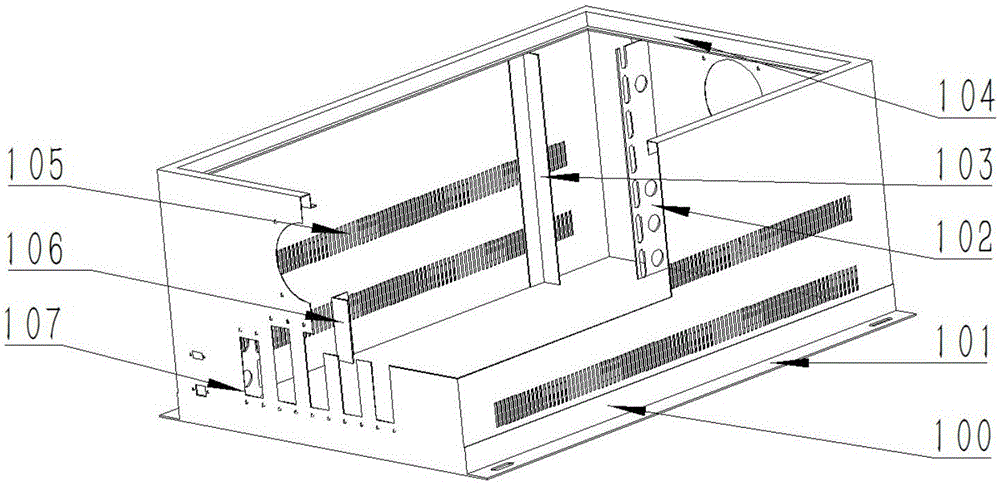

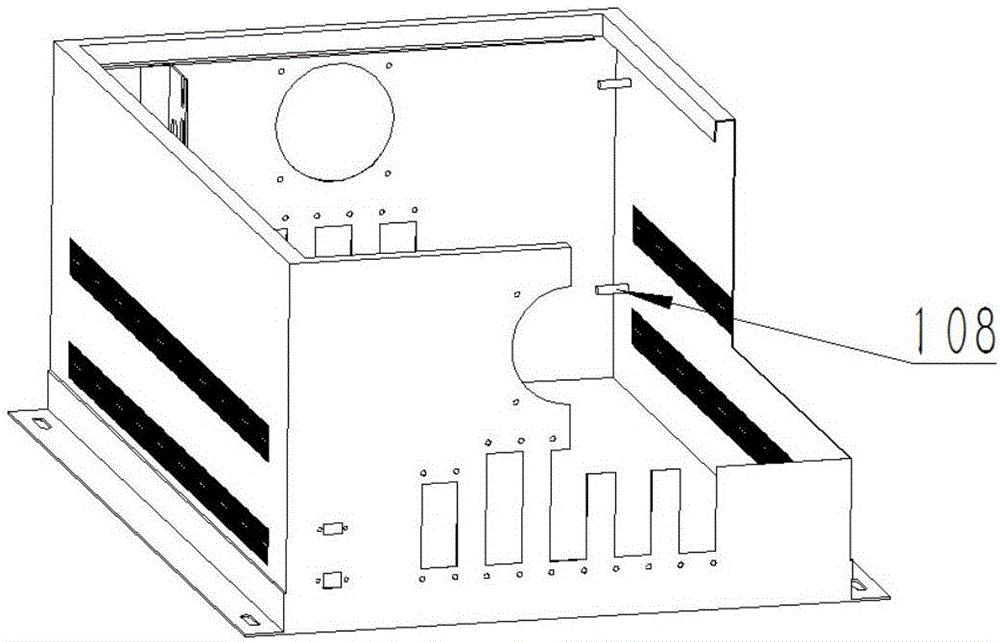

[0033] A cabinet door 13 is installed above the cabinet body 100, and the cabinet door 13 is hinged on the cabinet body 100 through a detachable door shaft; a driver mounting plate 12 and a component mounting plate 11 are installed inside the cabinet body 100, wherein the driver mounting plate 12 and the component mounting plate The boards 11 are all arranged along the length direction of the cabinet body 100, and both are parallel to each other. Side edges 101 for fixing the cabinet body 100 extend out from the two long sides of the cabinet body 100 along the length direction, and the side edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com