Camera self-calibration method based on two-dimensional mark code

A marking code and self-calibration technology, applied in the field of three-dimensional modeling, can solve the problems of high precision requirements, difficult to make three-dimensional targets, and poor accuracy of self-calibration method results, so as to improve robustness, facilitate identification, and avoid false matching. The effect of feature points of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

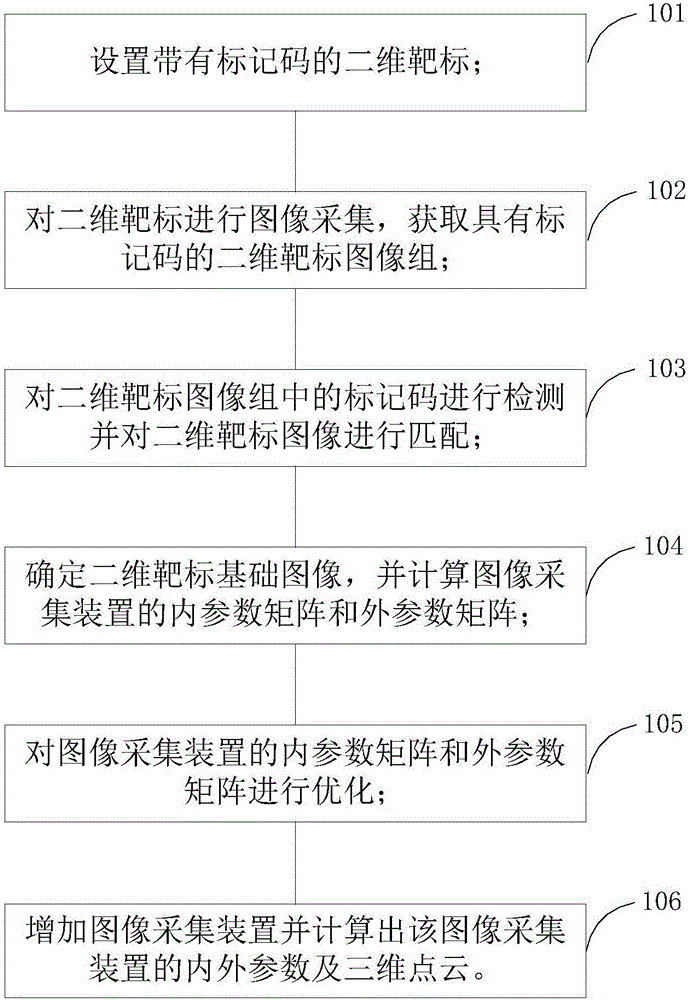

[0023] see figure 1 , is a flow chart of a camera self-calibration method based on a two-dimensional marker code proposed by the present invention.

[0024] Such as figure 1 Shown, a kind of camera self-calibration method based on two-dimensional marking code is characterized in that, comprises the following steps:

[0025] Step 101, setting a two-dimensional target with a marking code;

[0026] Step 102, image acquisition is performed on the two-dimensional target, and a two-dimensional target image group with a marking code is obtained;

[0027] Step 103, detecting the marking codes in the two-dimensional target image group and matching the two-dimensional target images;

[0028] Step 104, determine the basic image of the two-dimensional target, and calculate the internal parameter matrix and external parameter matrix of the image acquisition device;

[0029] Step 105, optimizing the internal parameter matrix and external parameter matrix of the image acquisition device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com