A system and method for recovering heavy hydrocarbons with carbon three or more in natural gas

A natural gas and heavy hydrocarbon technology, which is applied in the field of natural gas condensate recovery, can solve the problems of large system pressure drop, complicated technical process of mixed hydrocarbon technology, and large number of equipment, and achieve the effect of low refrigeration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

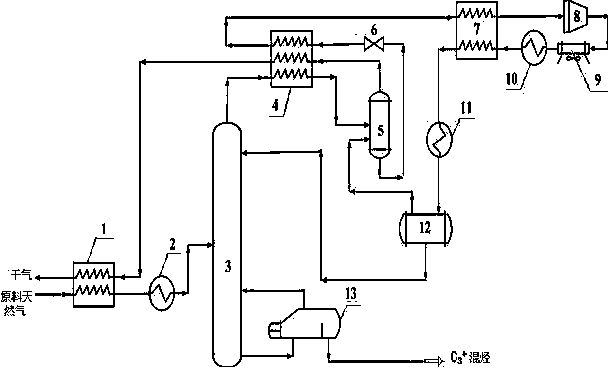

[0027] This embodiment provides a system for recovering heavy hydrocarbons above C3 in natural gas, including cold box I1, propane evaporator I2, deethanizer 3, cold box II4, low temperature separator 5, reboiler 13 and compressor 8. Air cooler 9, water cooler 10, cold box III 7, propane evaporator 11, liquid separator 12;

[0028] The outlet of cold box I1 is connected to the inlet of propane evaporator I2 through pipelines, the outlet of propane evaporator I2 is connected to the middle of deethanizer 3 through pipelines, the inlet end of cold box II4 is connected to the top of deethanizer 3, and the outlet end is connected to low temperature separator 5 are connected by pipelines, the top outlet of the low-temperature separator 5 is connected to the cold box I1 through the pipeline, the bottom outlet is connected to the inlet of the compressor 8 through the pipeline, and the outlet of the compressor 8 is connected to the air cooler 9, the air cooler 9, the water cooler 10, th...

Embodiment 2

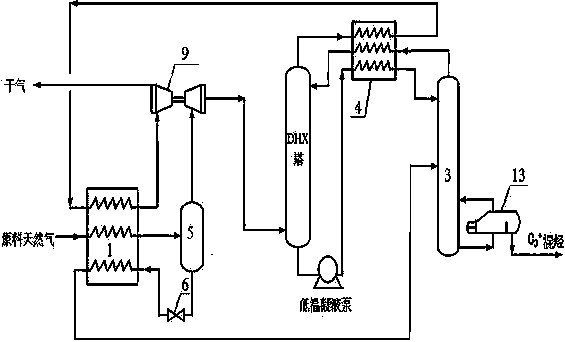

[0031] On the basis of Example 1, this example provides a system for recovering heavy hydrocarbons of C3 or more in natural gas, the top outlet of the low-temperature separator 5 is connected to the cold box I1 through a pipeline and the cold box II4.

[0032] The gas phase discharged from the top of the low-temperature separator 5 provides cooling capacity for the cold box II4, and then the gas phase enters the cold box I1 to exchange heat with the raw natural gas.

[0033] A throttle valve 6 is also provided between the bottom outlet of the low-temperature separator 5 and the inlet of the compressor 8, the outlet of the throttle valve 6, the cold box II4, and the cold box III7 are sequentially connected in series, and the outlet of the cold box III7 is connected to the compressor 8 The inlet port is connected.

[0034] The liquid phase discharged from the bottom outlet of the low-temperature separator 5 is depressurized by the throttle valve 6, the temperature drops, and ret...

Embodiment 3

[0037] On the basis of Embodiment 2, this embodiment provides a method for recovering heavy hydrocarbons with carbon three or more in natural gas, comprising the following steps:

[0038] Step 1) The raw natural gas is pre-cooled through the cold box I1 and the propane evaporator I2 in sequence, and then enters the middle part of the deethanizer 3;

[0039] Step 2) The gas phase at the top of the deethanizer 3 enters the cold box II 4 to be cooled to -50°C ~ -70°C, and then enters the low-temperature separator 5 to be divided into two phases of gas and liquid; wherein, the gas phase returns to the cold box II 4 for heat exchange, and the liquid After being depressurized by the throttle valve 6, the phase returns to the cold box II 4 for heat exchange;

[0040] Step 3) The gas phase after the heat exchange in step 2) enters the cold box I1 and then exchanges heat with the raw natural gas;

[0041] Step 4) The liquid phase after the heat exchange in step 2) enters the cold box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com