A spring-charged air duct valve for sealing

A power-storage, air duct technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of uncontrollable sealing and pressing force, large workload of air duct valves, etc., and achieve low workload , The effect of controllable sealing compression force and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

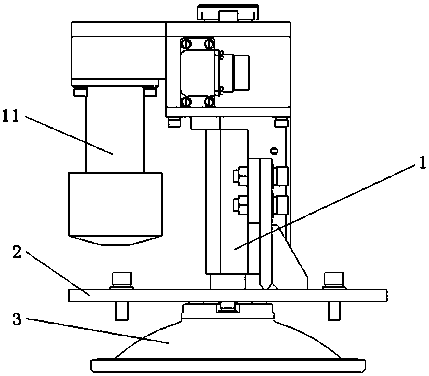

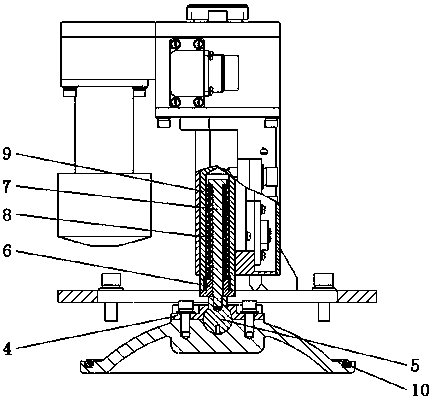

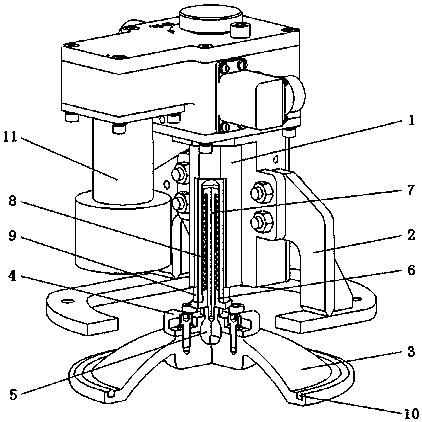

[0012] A spring-loaded air duct valve for sealing, including: a plugging cover 3, a screw 9, a sealing ring 10, and a motor 11, and also includes: a body 1, a fixing frame 2, a bearing bush 4, a ball head 5, and a retaining ring 6, pull bar 7 and stage clip 8.

[0013] The fixed frame 2 is a support for the spring-loaded air duct valve used for sealing. The fixed frame 2 is an oblong left and right symmetrical support structure. The two vertical plates of the fixed frame 2 have oblong holes along the up and down direction; the body There are four light holes on 1, and the screws pass through the light holes on the body 1 and the oblong holes on the fixing frame 2 to fix the body 1 and the fixing frame 2. The lead screw 9 and the body 1 cooperate through a screw pair; the lower half of the lead screw 9 is hollow, the inner cavity is threaded, and the retaining ring 6 and the lead screw 9 are threadedly connected. Pull bar 7 lower ends are threaded, and retaining ring 6 center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com