Rod taking device for broken rod of thread connecting rod piece and construction method thereof

A technology of threaded connecting rods and construction methods, which is applied in the fields of drill pipes, earthwork drilling, sustainable buildings, etc., and can solve the problem that broken rods of threaded connecting rods cannot be taken out, so as to ensure convenience and effectiveness, and save maintenance costs , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

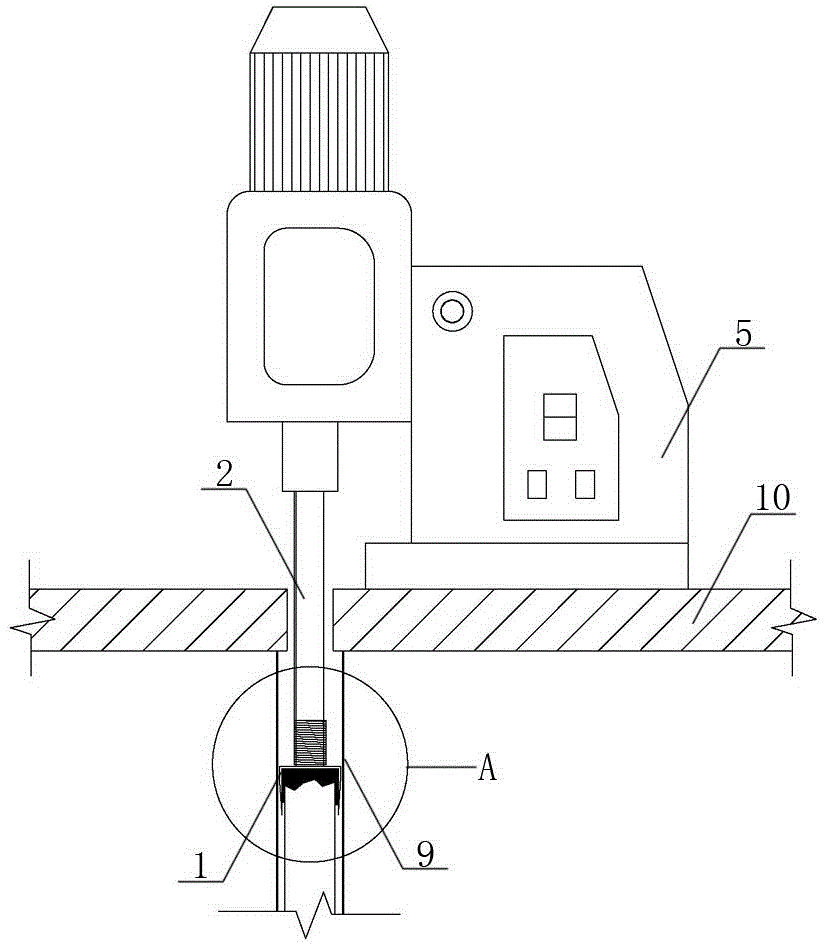

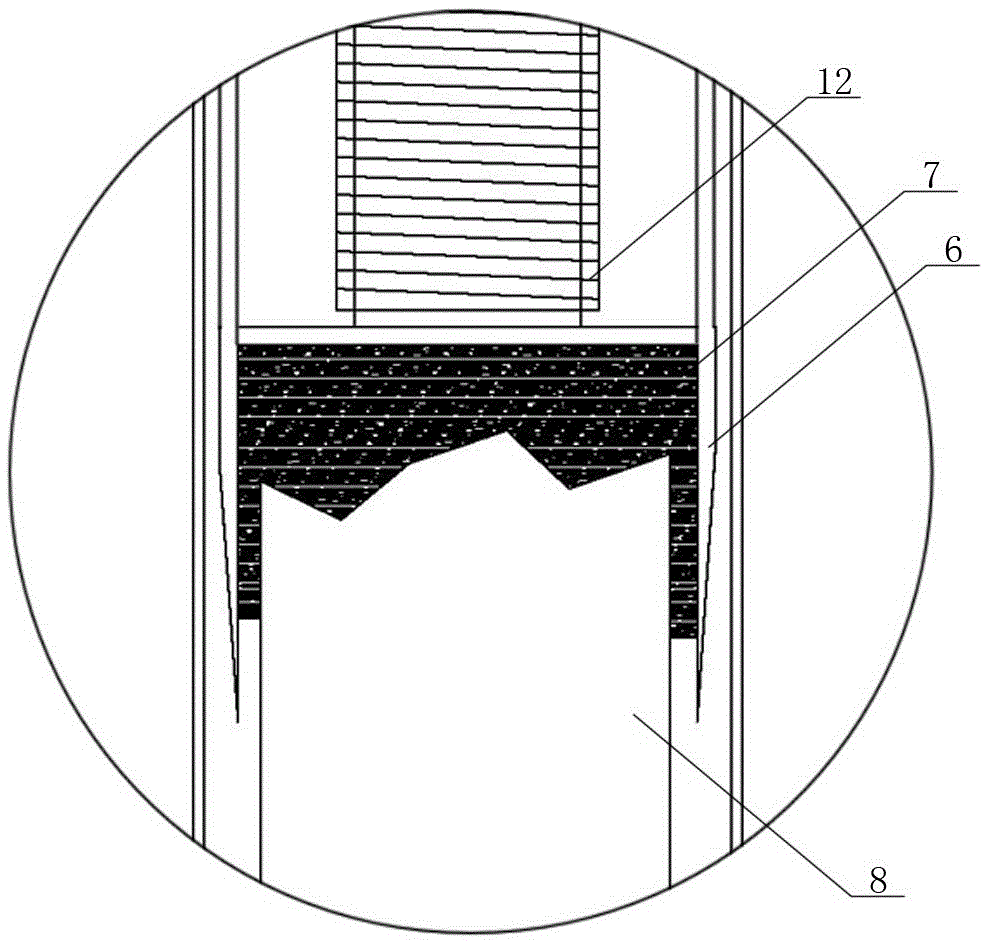

[0047] Embodiment one sees figure 1 As shown, this device for taking broken rods with threaded rods includes a drill base 5 and a drill rod 2 connected to the drill base 5, the end of the drill rod 2 is detachably connected with a connecting joint 1; the drill The rod 2 is formed by detachably connecting a group of rod joints 3 in sequence.

[0048] The drill rod 2 is a straight shank drill rod, and its end is connected with the drill base 5 through a straight shank clamp.

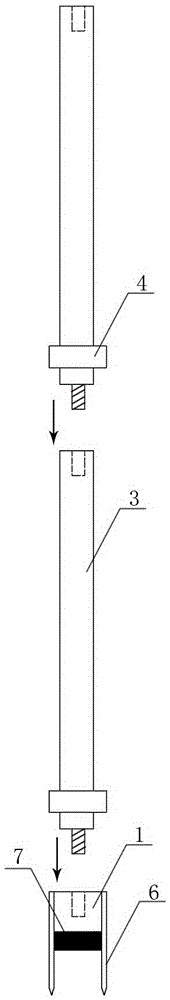

[0049] see image 3 As shown, the center of one end of the rod section 3 is provided with a threaded blind hole, and the center of the other end is correspondingly provided with a threaded joint, and the adjacent rod sections 3 are threaded; the length of the rod section 3 is 200mm, 300mm, 500mm And three or four specifications of 1000mm; the rod joint 3 is sleeved with an annular limiter 4; the limiter 4 is a bearing or a bushing, which is sleeved on the shaft of the rod joint 3 and passes through the r...

Embodiment 2

[0067] Embodiment two see Figure 4 As shown, the difference from the first embodiment is that one end of the rod joint 3 is welded or interference-fitted with a limit sleeve 11, and the other end is provided with an external thread, and the adjacent rod joints 3 are passed through a limit sleeve. The connection joint 1 includes a connection base and a sheath 6 vertically connected to the connection base; the upper end surface of the base is provided with a connection hole for use with the external thread of the end of the rod joint; the rod joint passes through a limit The outer diameter of the limiting sleeve is adapted to the diameter of the construction hole. One end of the limiting sleeve is welded to the rod joint 3 or the other end is threaded with the rod joint through interference fit to realize the adjacent rod joints. detachable connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com