Large vacuum container door operating mechanism

A technology of vacuum container and operating mechanism, applied in the direction of power control mechanism, control mechanism of wing fan, door/window accessories, etc. sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. These embodiments are only exemplary and are not intended to limit the protection scope of the present invention.

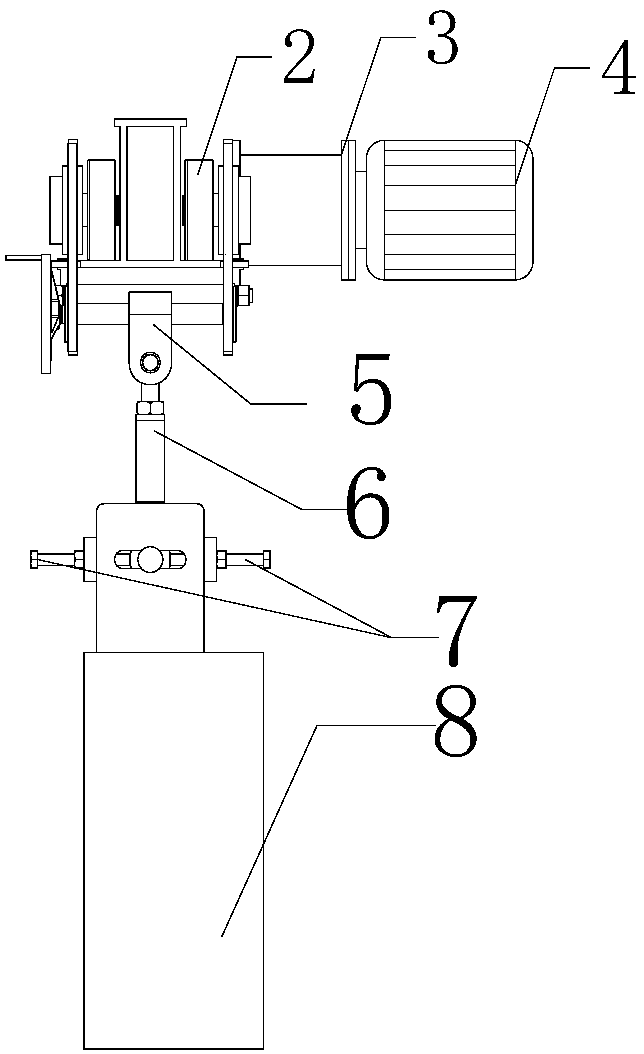

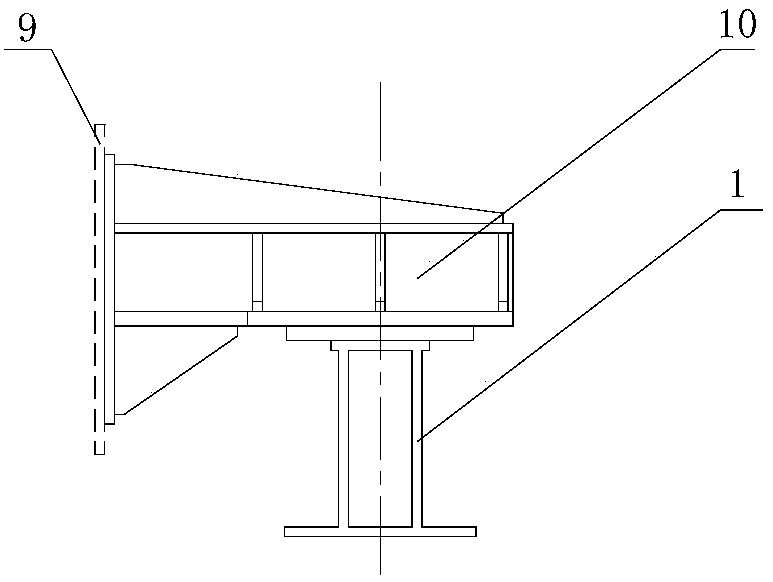

[0022] Referring to Fig. 1, Fig. 1 is a schematic diagram of a large-scale vacuum container door operating mechanism according to an embodiment of the present invention. The large-scale vacuum container door operating mechanism of the present invention is mainly used for the translational opening and closing of the large-scale vacuum container door, and includes a walking track 1, two sets of drive travel suspension devices and a gate clamping mechanism, wherein the two drive travel suspension devices include respectively The driving wheel 2, the clutch 3, the motor 4, the height adjustment mechanism and the center of gravity adjustment mechanism that roll and walk in the walking track 1, the walking track 1 is connected and fixed to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com