Foundation high-pressure jet grouting device

A high-pressure jetting and foundation technology, which is used in infrastructure engineering, soil protection, construction, etc., can solve the problems of jet grouting use, unsuitable for foundations of different depths, etc., and achieve the effect of expanding the length of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

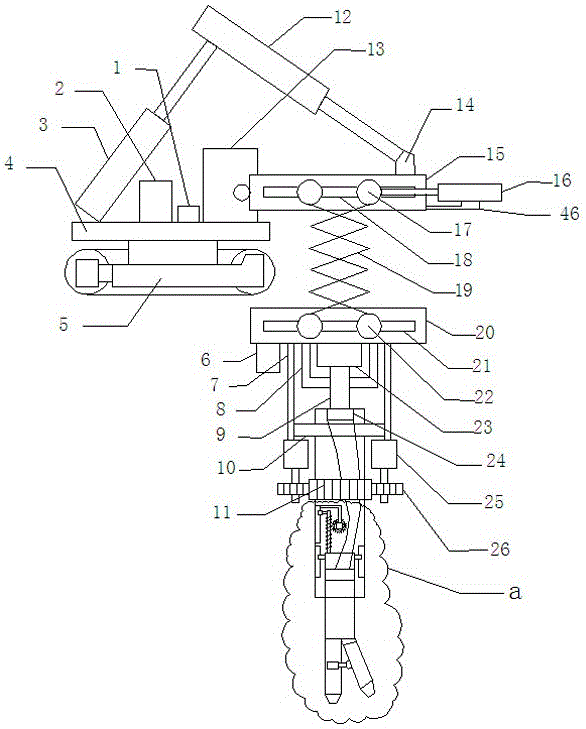

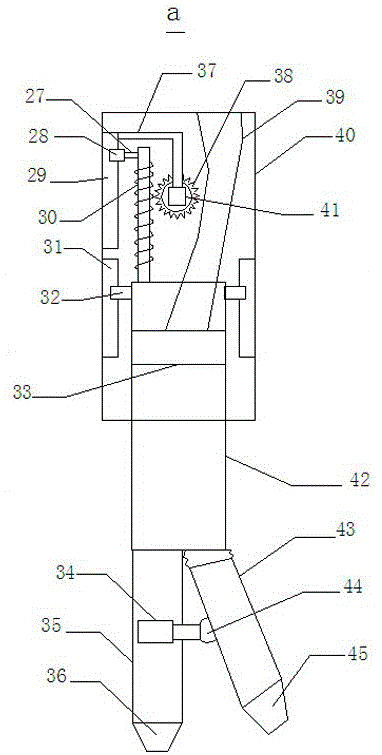

[0016]A high-pressure jet grouting device for a foundation of the present invention includes a controller 1, a slurry storage tank 2, a first cylinder 3, a platform 4, a crawler transport vehicle 5, a mud pump 6, a bracket 7, a bracket 8, a first pipeline 9, Flange bearing 10, first gear 11, second cylinder 12, first motor 13, first fisheye bearing 14, first support plate 15, third cylinder 16, first pin shaft 17, first hollow 18, shear Fork arm 19, second platen 20, second hollow 21, second pin shaft 22, high pressure pump 23, first pipe connector 24, second motor 25, second gear 26, connecting rod 27, first slider 28. The first slide rail 29, the worm 30, the second slide rail 31, the second slider 32, the second pipe connector 33, the fourth cylinder 34, the first through pipe 35, the first nozzle 6, the frame 37, Worm wheel 38, rubber tube 39, seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com