An automatic production line for hot-dip galvanizing of steel pipes

An automatic production line, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as high requirements, equipment failure, workshop environmental pollution, etc. The effect of reducing environmental protection energy consumption and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

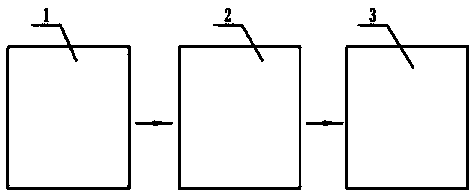

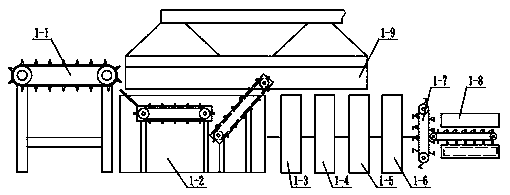

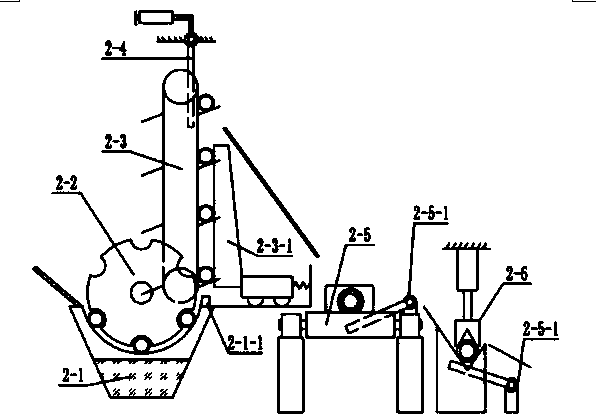

[0019] Depend on figure 1 , figure 2 Known, the present invention a kind of steel pipe hot-dip galvanizing automatic production line, is made up of steel pipe pretreatment mechanism 1, steel pipe automatic hot-dip galvanizing mechanism 2, galvanized post-processing mechanism 3, steel pipe pretreatment mechanism 1, steel pipe automatic hot-dip galvanizing mechanism 2 and galvanized post-processing mechanism 3 are installed on the ground from left to right. The steel pipe pre-processing mechanism 1 consists of a horizontal feed conveying mechanism 1-1, an oil removal and cleaning mechanism 1-2, and a neutralization and cleaning mechanism 1-3. , pickling rust removal mechanism 1-4, twice cleaning mechanism 1-5, soaking solvent mechanism 1-6, vertical lifting mechanism 1-7 into the oven, pretreatment oven 1-8, and mist suction cover 1-9, horizontal Feeding and conveying mechanism 1-1, degreasing and cleaning mechanism 1-2, neutralization and cleaning mechanism 1-3, pickling and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com