Method for refining polyoxymethylene dimethyl ether

A technology of dimethyl ether and polyoxymethylene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

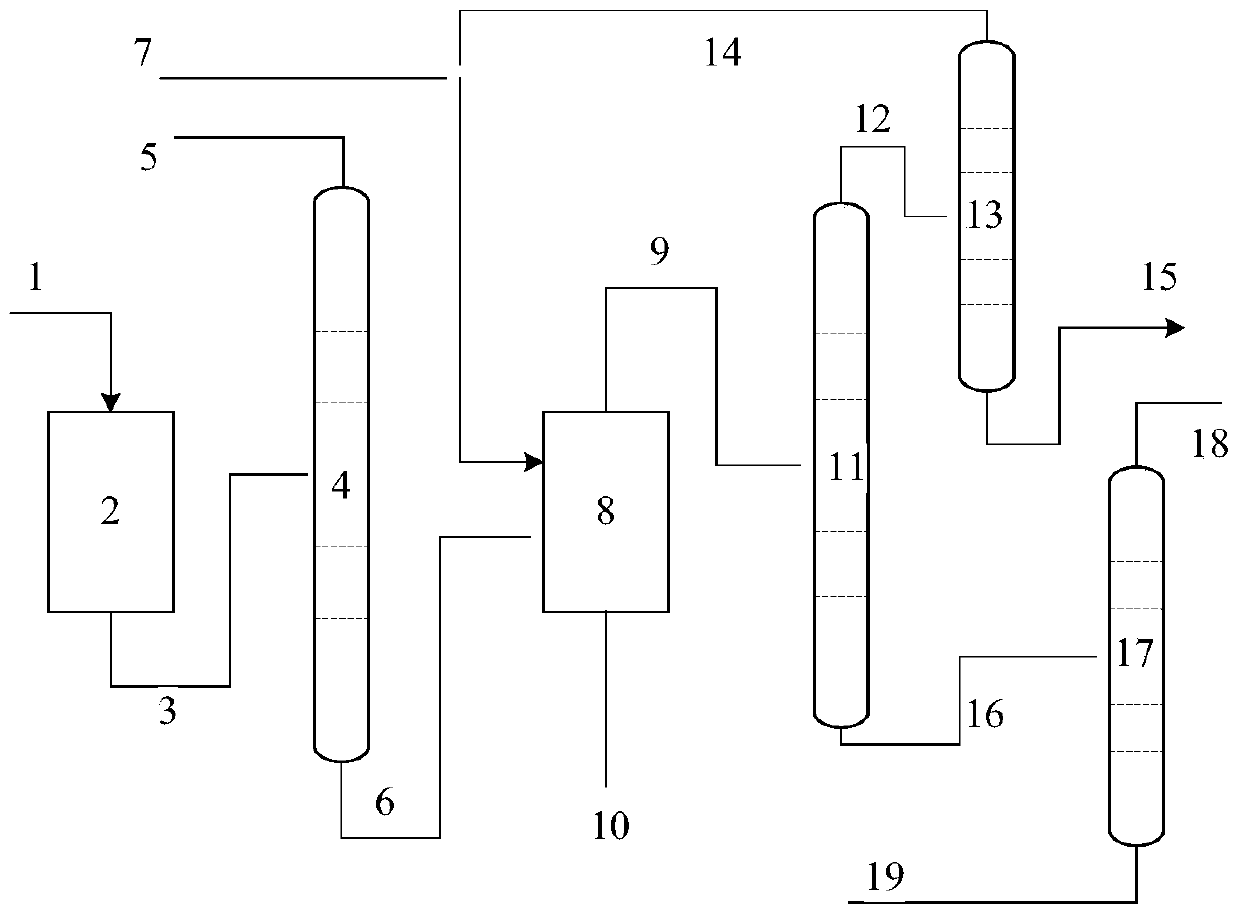

Method used

Image

Examples

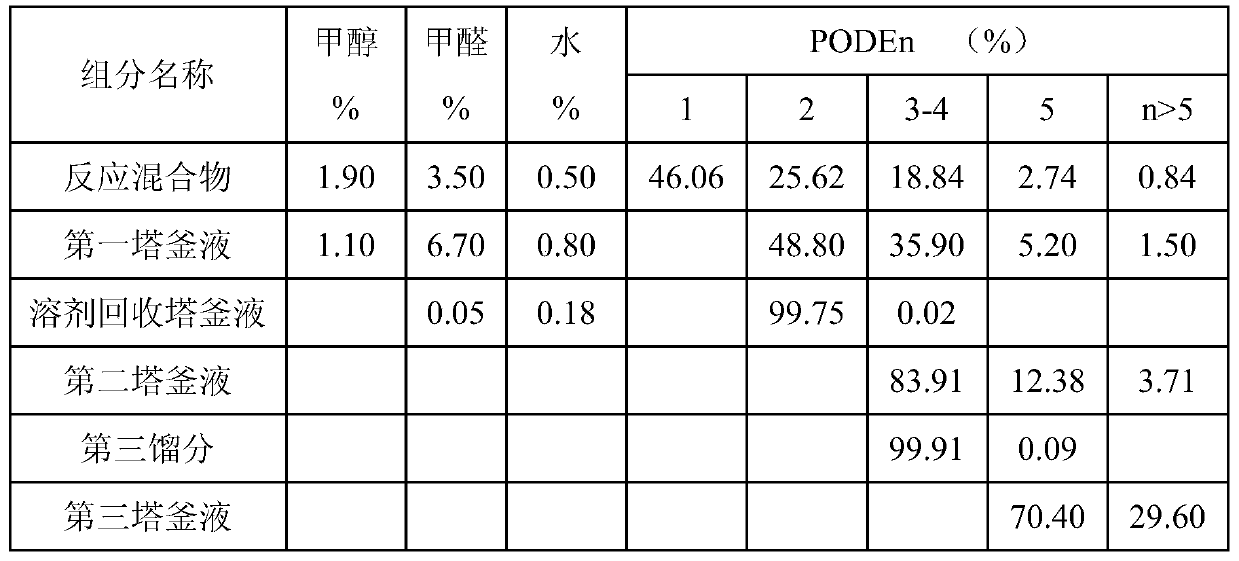

Embodiment 1

[0033]The neutral reaction mixture obtained by the reaction unit is firstly passed through the first rectification tower to remove the first fraction DMM by rectification at 0.1 MPa, a reflux ratio of 1, and a tower bottom temperature of 105°C. The two-phase extractant composed of water and cyclohexane in a ratio of 1:1, enters the extraction tower with the ratio of 2:1 with the liquid in the first tower, and the extracted phase enters the second rectification tower. The operating conditions are 0.08MPa, The reflux ratio is 8, the temperature of the tower bottom is 150°C, the second fraction containing cyclohexane solvent and n=2 polyoxymethylene dimethyl ether is obtained from the top of the tower, and the polyoxymethylene dimethyl ether containing n=3-8 is obtained from the tower bottom The second tower still liquid. The second fraction enters the solvent recovery tower, and is rectified under the conditions of normal pressure, reflux ratio of 2, and tower bottom temperature...

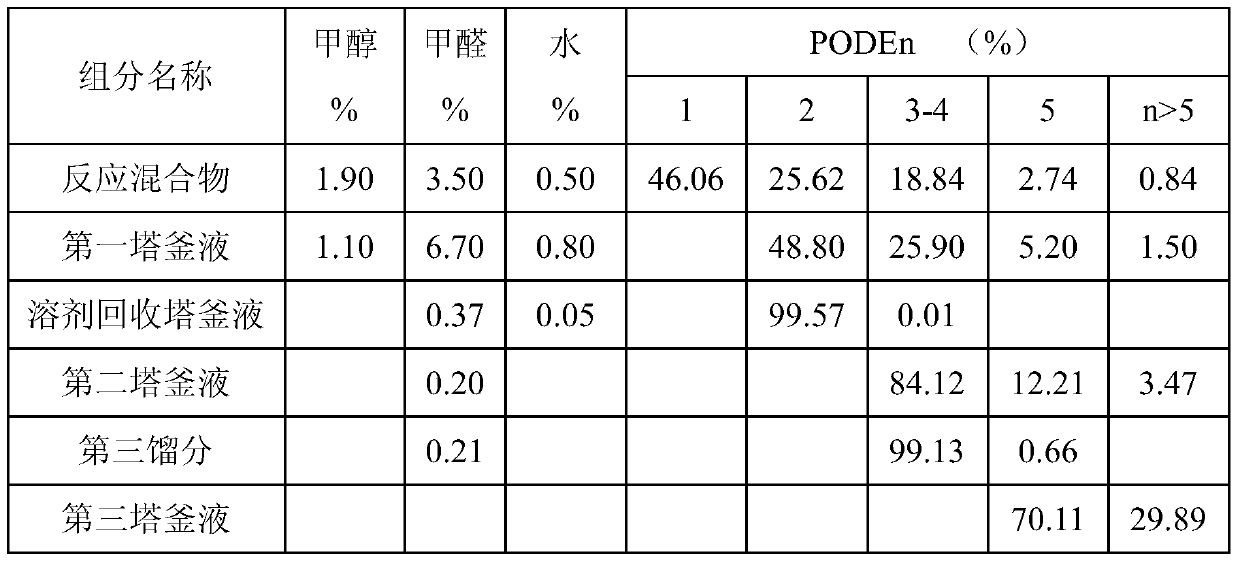

Embodiment 2

[0037] The neutral reaction mixture obtained by the reaction unit is firstly passed through the first rectification tower to remove the first fraction DMM by rectification under the conditions of 0.05MPa, reflux ratio of 3, and tower bottom temperature of 88°C. A two-phase extractant composed of NaOH-containing aqueous solution and n-hexane at a ratio of 0.2:1, enters the extraction tower at a ratio of 1:5 with the bottom liquid of the first tower, and the extracted phase enters the second rectification tower at an operating condition of 0.05 MPa, the reflux ratio is 4, the temperature of the tower bottom is 130 °C, the second fraction containing n-hexane solvent and n=2 polyoxymethylene dimethyl ether is obtained from the top of the tower, and the polyoxymethylene dimethyl ether containing n=3-8 is obtained from the tower bottom The second tower bottom liquid of ether. The second fraction enters the solvent recovery tower and is rectified under the conditions of 0.1MPa, reflu...

Embodiment 3

[0039] Using paraformaldehyde and methylal as raw materials, the reaction mixture obtained after acid catalysis is firstly passed through the first rectification tower to remove the first distillate DMM by rectification at 0.15MPa, reflux ratio of 0.5, and tower bottom temperature of 125°C The two-phase extractant that water and normal heptane form with the ratio of 3:1 enters the extraction and separation pump with the ratio of 4:1 with the first tower bottom liquid, obtains the extraction phase and enters the second rectifying tower, and the operating condition is 0.03MPa , the reflux ratio is 1, the temperature of the tower bottom is 116 ° C, the second fraction containing n-heptane solvent and n=2 polyoxymethylene dimethyl ether is obtained at the top of the tower, and the polyoxymethylene dimethyl ether containing n=3-8 is obtained from the tower bottom The second tower bottom liquid of ether. The second fraction enters the solvent recovery tower and is rectified under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com