Riser self-tensioning type underwater production support buoy and mounting and recycling method thereof

A technology of buoys and risers, applied in the field of underwater production support buoys and their installation and recovery, can solve the stress change of the main body of the rigid riser, the increase of the tension force at the top of the rigid riser, the unfavorable rigid riser strength and fatigue resistance Performance and other issues to achieve the effect of improving strength and fatigue performance, reducing force and range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

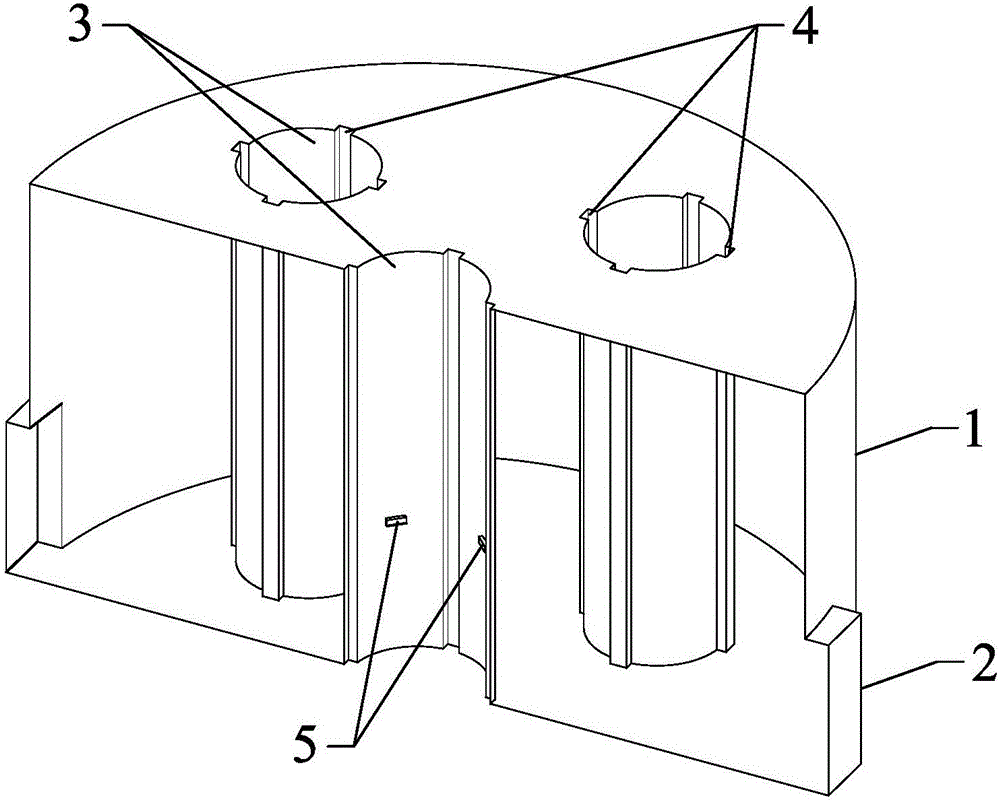

[0063] The self-tensioning underwater production support buoy in the present invention will be further described below with reference to the accompanying drawings. The illustration of the present invention takes the self-tensioning underwater production support buoy in an ultra-deep water offshore oil and gas engineering development system with five rigid risers as an example.

[0064] Such as Figure 1-7 As shown, a standpipe self-tensioning type underwater production support buoy includes an outer layer buoy 1 and an inner layer buoy 6, wherein the outer layer buoy 1 is nested with a plurality of inner layer buoys 6;

[0065] The main body of the outer pontoon 1 is a cylindrical structure, and the lower edge of the outer wall of the outer pontoon 1 is connected to four cantilever pontoons 2, which are evenly distributed in the circumferential direction and in a radial shape. The end of the cantilever pontoon 2 adopts a truss structure 15. The outer end of the structure 15 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com