Koldfoil technology and device for flexographic printing of tissue

A technology for printing devices and paper towels, which is applied in printing process, printing devices, laminating devices, etc. It can solve the problems of increased difficulty in implementation and failure to achieve eight-color printing, so as to improve the fixing effect, improve printing quality, and avoid scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

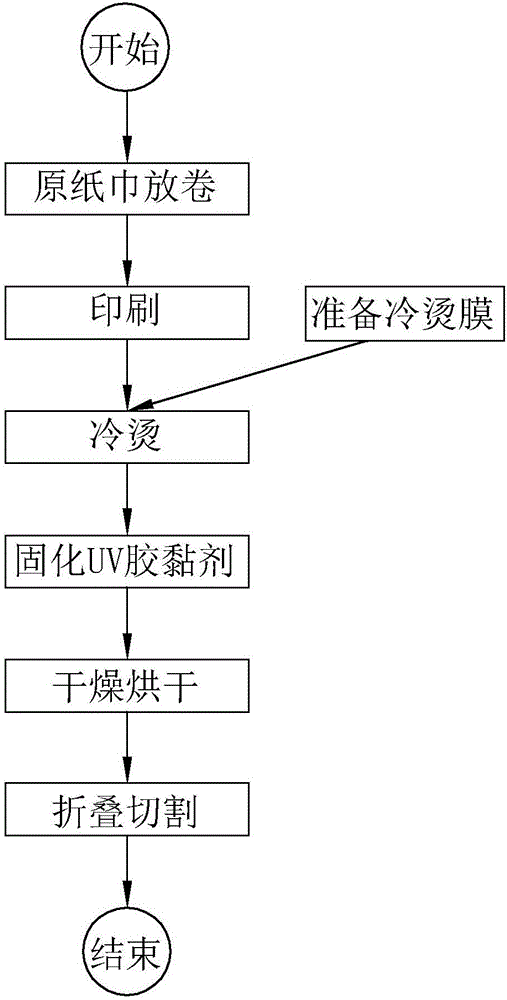

[0052] see figure 1 , a cold stamping process for tissue flexo printing, comprising the following steps:

[0053] S1. Raw paper towel unwinding:

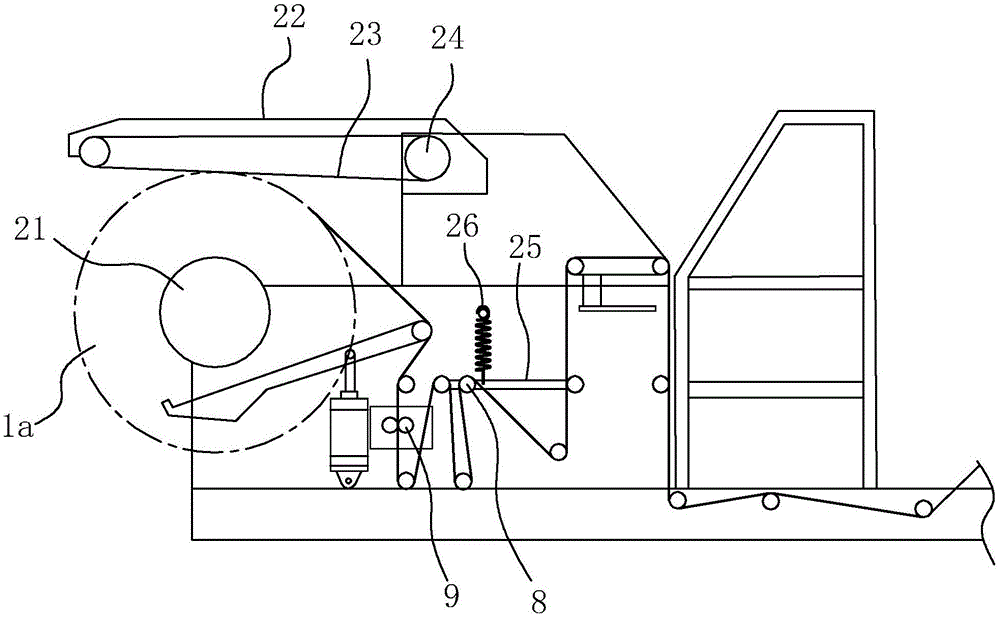

[0054] Using a flexographic printing machine, install the raw paper towel after winding on the paper towel unwinding roller of the flexographic printing machine, adjust the belt so that the outer surface of the belt is in conflict with the original paper towel, turn on the drive motor to drive the belt to convey, and pass the belt The friction between the raw paper towel and the original paper towel can realize the unwinding of the original paper towel, and control the anti-rolling speed of the original paper towel to 100m / min;

[0055] S2. Printing:

[0056] The raw paper towels after unwinding are flexo-printed sequentially through multiple printing devices on the flexographic printing machine, and a pre-printing is performed after the flexo printing is completed, and a layer of pre-printed ink is coated on the surface of the ra...

Embodiment 2

[0068] A cold ironing process for tissue flexo printing, the difference from Example 1 is that the power of the UV lamp in S5 is 210W, and the heating temperature of the oven in S6 is 355°C.

Embodiment 3

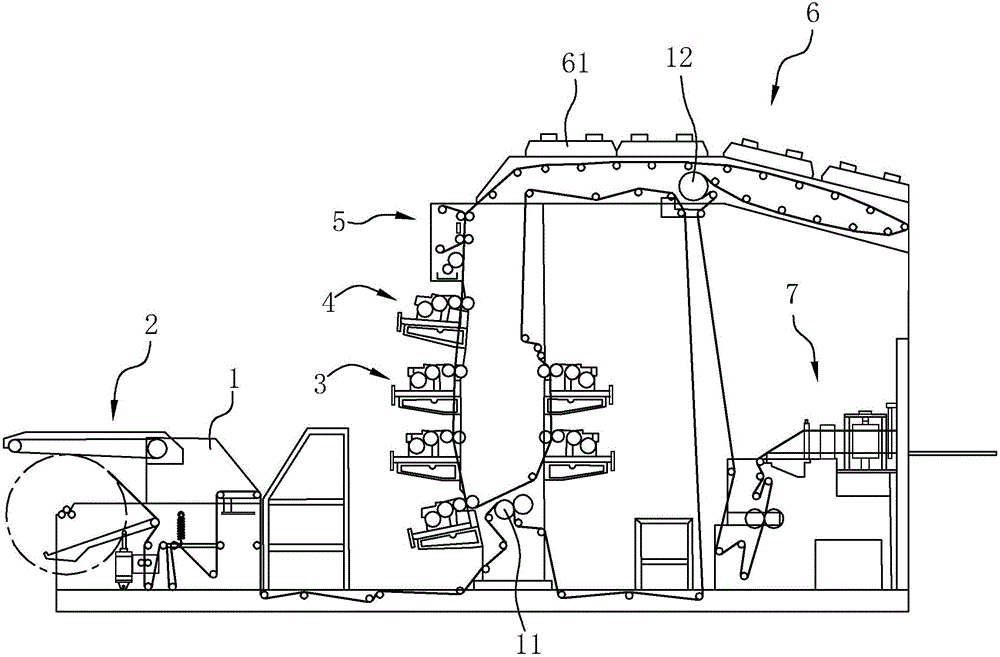

[0070] see figure 2 , a cold ironing device for tissue flexo printing, including a frame 1, an unwinding device 2 is arranged on the frame 1, five printing devices 3 are connected to the outlet end of the unwinding device 2, and each printing device 3 is responsible for printing a A pre-printing device 4 is connected to the outlet of the last printing device 3. The difference between the pre-printing device 4 and other printing devices 3 is that the pre-printing ink is used as printing oil. The outlet end of the pre-printing device 4 is connected with a cold ironing mechanism 5, and the outlet end of the cold ironing mechanism 5 is connected with a drying device 6. The drying device 6 includes a plurality of ovens 61 connected in series. In the oven 61, an infrared heating device and a drying device are installed. The outlet end of 6 is connected with paper towel folding device 7. Also be provided with the first driving roller 11 and the second driving roller 12 on the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com