Vertical high-speed high-accuracy direct-driving mechanism

A vertical, high-precision technology, used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of shortening the service life of the mechanism, slow movement speed, mechanical wear and backlash, etc., to overcome vibration, Long life, avoid mechanical wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

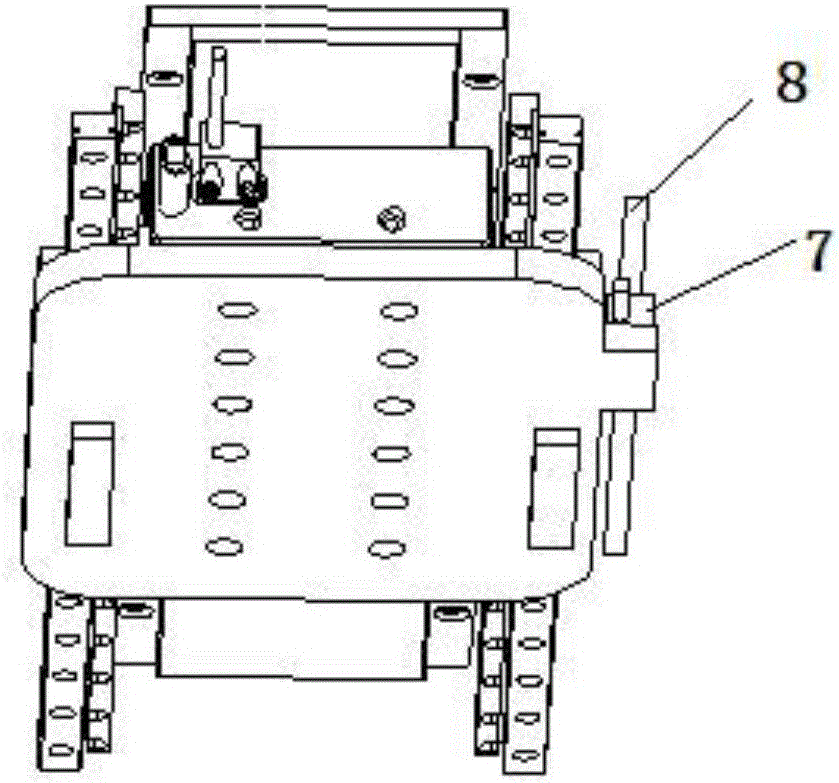

[0017] see Figure 1 to Figure 3 , a high-speed and high-precision direct drive mechanism in the vertical direction, including a vertically placed base 1, two vertically placed slide rails 4 arranged on the base 1, a linear motor primary 2 and a linear motor secondary 3, the linear motor The motor primary 2 is installed on the base 1, the linear motor secondary 3 is connected with a mobile carrier 6, and the mobile carrier 6 is provided with a slider 5, the slider 5 is engaged on the slide rail 4 and moves along the slide rail 4, The inner side of the slide rail 4 is provided with an adjustment block 41, which is used to assist in adjusting the accuracy of the slide rail. The primary 2 of the linear motor and the secondary 3 of the linear motor are arranged oppositely. The secondary 3 of the motor is energized to generate a traveling wave magnetic field; the traveling wave magnetic field interacts with the permanent magnetic field to directly generate electromagnetic thrust, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com