Steel reinforcement cage machining platform in civil construction water conservancy and soil conservation pile foundation project

A technology of civil construction and processing platform, applied in the direction of wire rod processing, wire manufacturing of ring nets, and other household appliances, etc., can solve the problems of inconsistent processing equipment for steel cages, high labor consumption, and low quality of finished products, and save materials. and production cost, ease of loading and unloading construction, and the effect of a saving society

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

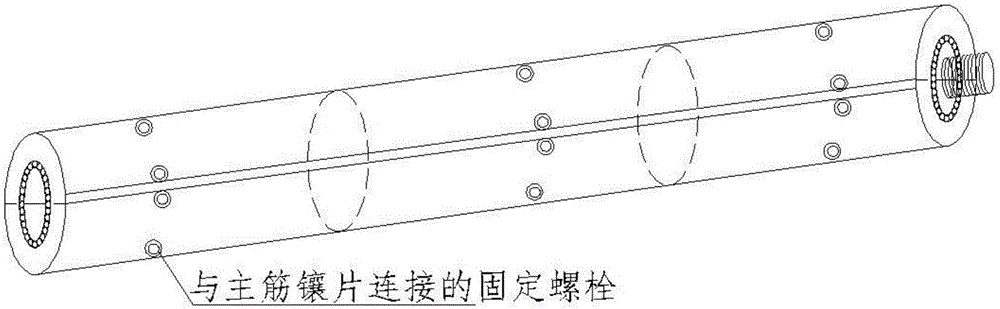

[0037] see figure 1 , figure 2 and Figure 7 , the present embodiment provides a steel cage processing platform in civil construction water conservancy and water conservation pile foundation engineering. The steel cage processing platform adopts a modular design, including a fixed bracket module and a fixed shaft module, wherein:

[0038] The fixed frame module is composed of a pair of fixed brackets, one of which has a positioning caliper, and the other fixed bracket has a finished steel cage outlet;

[0039] The fixed shaft module is composed of high cage module, middle cage module and low cage module; and the high cage module, middle cage module and low cage module are all composed of inner fixed shaft module and outer fixed shaft module; the inner fixed shaft module is connected by inner rolling bearing The external fixed shaft module, the surface of the external fixed shaft module is installed with several main reinforcement inserts along the outer circumference, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com