Cleaning brush idle shaft structure and usage method of cleaning equipment after cmp

A post-cleaning and cleaning brush technology, which is applied in the field of cleaning brush idler shaft structure, can solve the problems of poor wetting effect of cleaning brush, large concentricity deviation of idler shaft, poor bearing rigidity, etc., so as to improve rigidity, improve concentricity, The effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

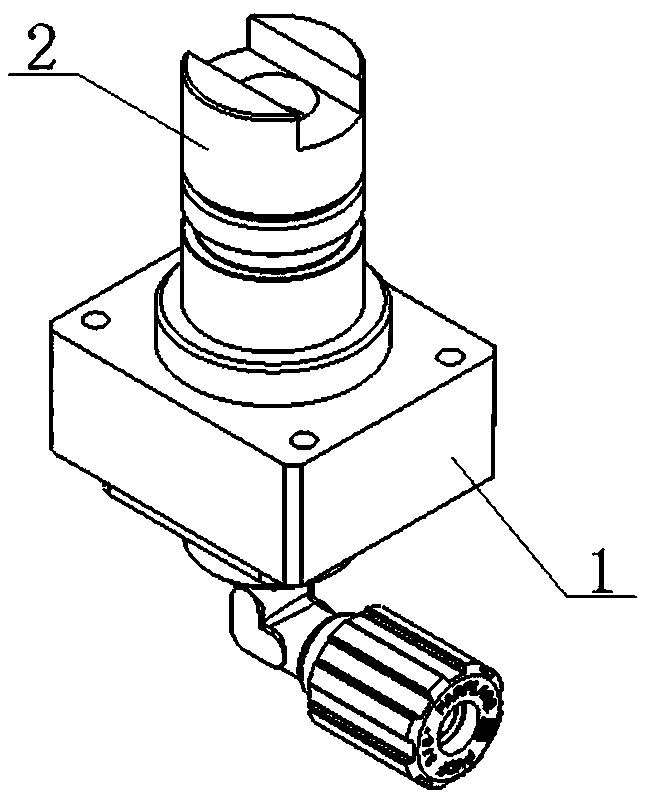

[0029] Examples see figure 1 , figure 2 As shown, the cleaning brush idle shaft structure of the post-CMP cleaning equipment includes a cavity unit 1 and an idle shaft unit 2 that is socketed with the cavity unit 1 .

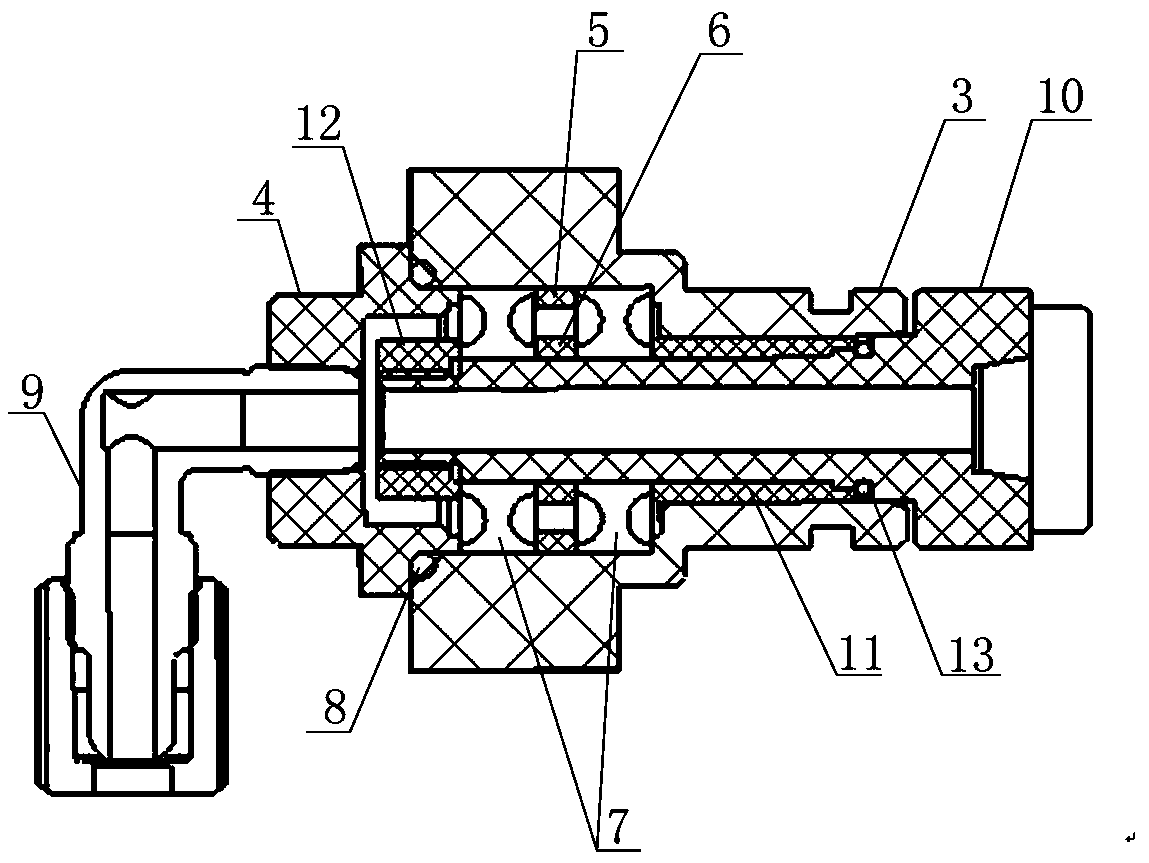

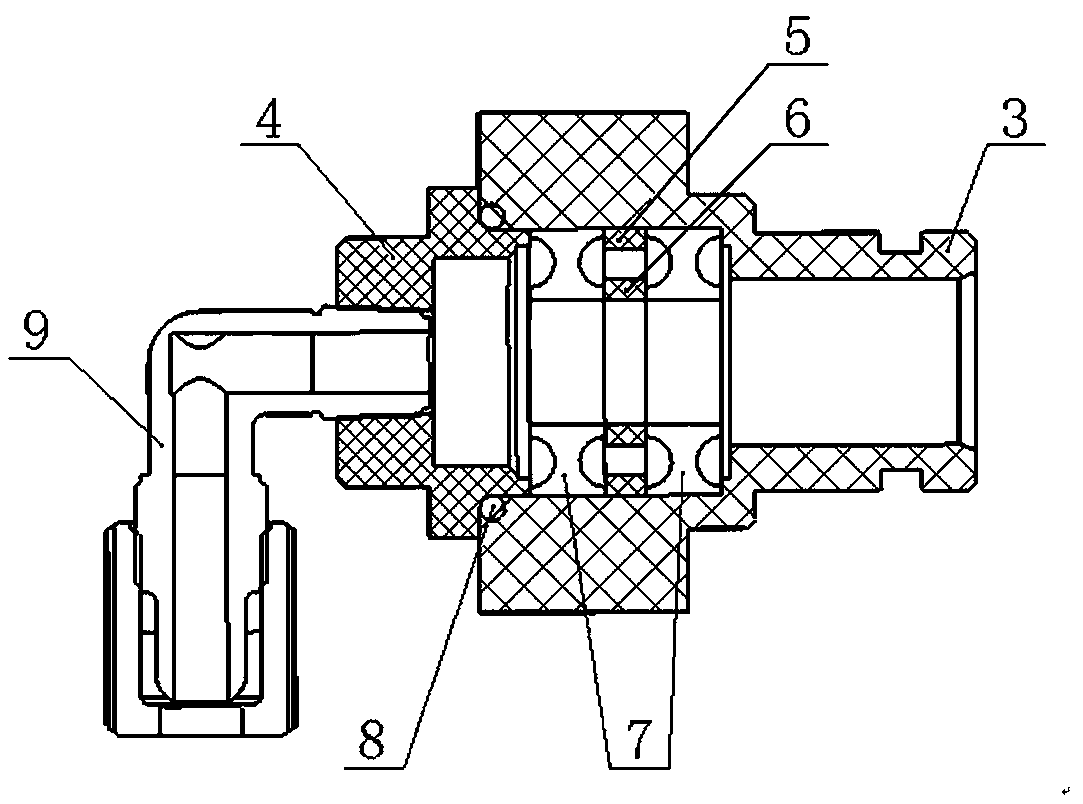

[0030] see image 3 As shown, the cavity unit 1 includes a cavity seat 3 , a combined bearing 7 , an outer spacer 5 , an inner spacer 6 , a gland 4 and a right-angle joint 9 . The combined bearing 7 is made of ceramic material, and the combined bearing 7 is pressed into the cavity seat 3 in a hole-axis positioning manner. The outer spacer 5 and the inner spacer 6 are between the bearings of the combined bearing 7 to eliminate backlash in the axial direction of the bearing. An O-ring 8 is provided between the front port of the gland 4 and the rear port of the cavity seat 3, and the O-ring 8 is tightly fitted and sealed. The right-angled joint 9 penetrates into the rear port of the gland 4 and is screwed tightly with the gland 4 for sealing.

[0031] see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com