A kind of preparation method of graphene-antimony sulfide microrod composite photocatalyst

A graphene and micro-rod technology is applied in the field of preparing graphene-antimony sulfide micro-rod composite photocatalyst, and achieves the effects of low implementation cost, excellent product quality and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

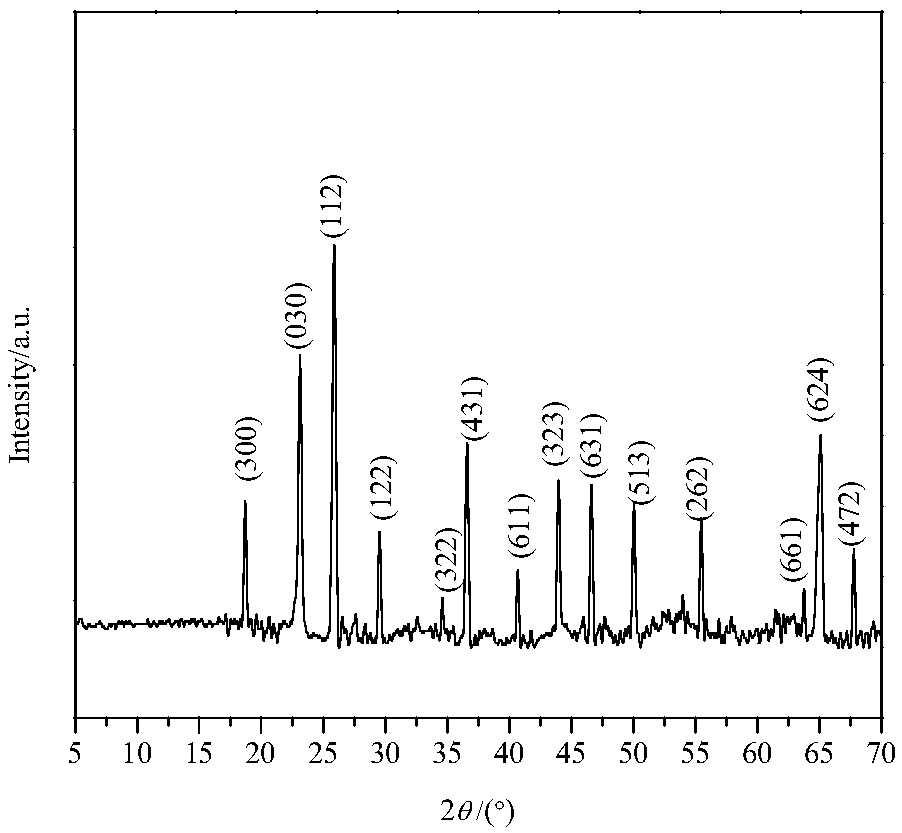

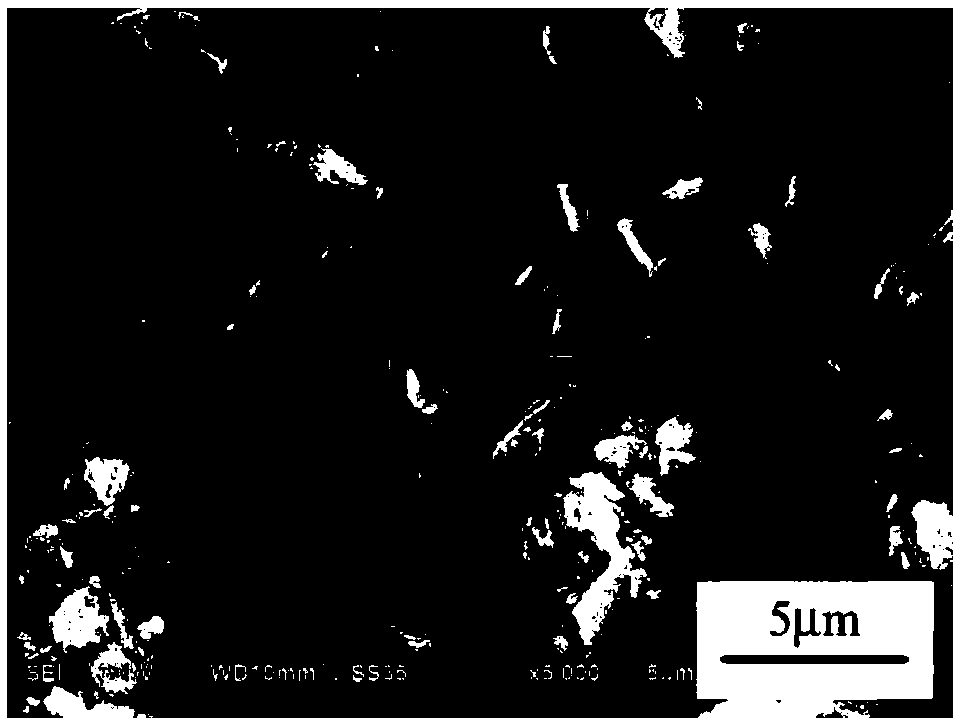

Image

Examples

Embodiment 1

[0025] (1) Weigh 30mg graphene oxide and add to 39mL deionized water (the amount of deionized water is SbCl 3 2166 times the amount of substance), ultrasonic stripping for 2 hours, to obtain graphene oxide-deionized water dispersion A;

[0026] (2) by SbCl 3 The ratio of the amount of substance to HCl is 1:48, and 0.23g SbCl 3 Dissolve in 4.0mL concentrated hydrochloric acid to get SbCl3 hydrochloric acid solution, then it was added to the above-mentioned graphene oxide-deionized water dispersion A, stirred evenly, to obtain mixed solution B;

[0027] (3) In 17mL deionized water (the amount of deionized water is SbCl 3 944 times the amount of substance), add 0.99g Na 2 S 2 o 3 ·5H 2 O, stirring to dissolve, Na 2 S 2 o 3 ·5H 2 The amount of O species is SbCl 3 4 times of the amount of substance; add 1.68g NaOH again, the ratio of NaOH and the amount of substance of HCl is 1:1.14, to obtain mixed solution C;

[0028] (4) Pour the mixed solution B into the mixed solut...

Embodiment 2

[0032] (1) Weigh 38mg graphene oxide and add it to 32mL deionized water (the amount of deionized water is SbCl 3 1975 times the amount of substance), ultrasonic stripping for 3 hours, to obtain graphene oxide-deionized water dispersion A;

[0033] (2) by SbCl 3 The ratio of the amount of substance to HCl is 1:40, and 0.21g SbCl 3 Dissolve in 3.0mL concentrated hydrochloric acid to get SbCl 3 hydrochloric acid solution, then it was added to the above-mentioned graphene oxide-deionized water dispersion A, stirred evenly, to obtain mixed solution B;

[0034] (3) In 12mL deionized water (the amount of deionized water is SbCl 3 740 times the amount of substance), add 0.67g Na 2 S 2 o 3 ·5H 2 O, stirring to dissolve, Na 2 S 2 o 3 ·5H 2 The amount of O species is SbCl 3 3 times of the amount of substance; add 1.20g NaOH again, the ratio of NaOH and the amount of substance of HCl is 1:1.20, to obtain mixed solution C;

[0035] (4) Pour the mixed solution B into the mixed ...

Embodiment 3

[0037] (1) Weigh 28mg graphene oxide and add it to 32mL deionized water (the amount of deionized water is SbCl 3 1616 times the amount of substance), ultrasonic stripping for 1 hour, to obtain graphene oxide-deionized water dispersion A;

[0038] (2) by SbCl 3 The ratio of the amount of substance to HCl is 1:22, and 0.25g SbCl 3 Dissolve in 2.0mL concentrated hydrochloric acid to get SbCl 3 hydrochloric acid solution, then it was added to the above-mentioned graphene oxide-deionized water dispersion A, stirred evenly, to obtain mixed solution B;

[0039] (3) In 13mL deionized water (the amount of deionized water is SbCl 3 656 times the amount of substance), add 0.55g Na 2 S 2 o 3 ·5H 2 O, stirring to dissolve, Na 2 S 2 o 3 ·5H 2 The amount of O species is SbCl 3 2 times of the amount of substance; add 0.72g NaOH again, the ratio of NaOH and the amount of substance of HCl is 1:1.33, to obtain mixed solution C;

[0040] (4) Pour the mixed solution B into the mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com