A denitrification system and method using catalytic hydrogen peroxide

A hydrogen peroxide and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as low utilization rate and incomplete oxidation, and achieve improved utilization rate, stable product quality, and reasonable process design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

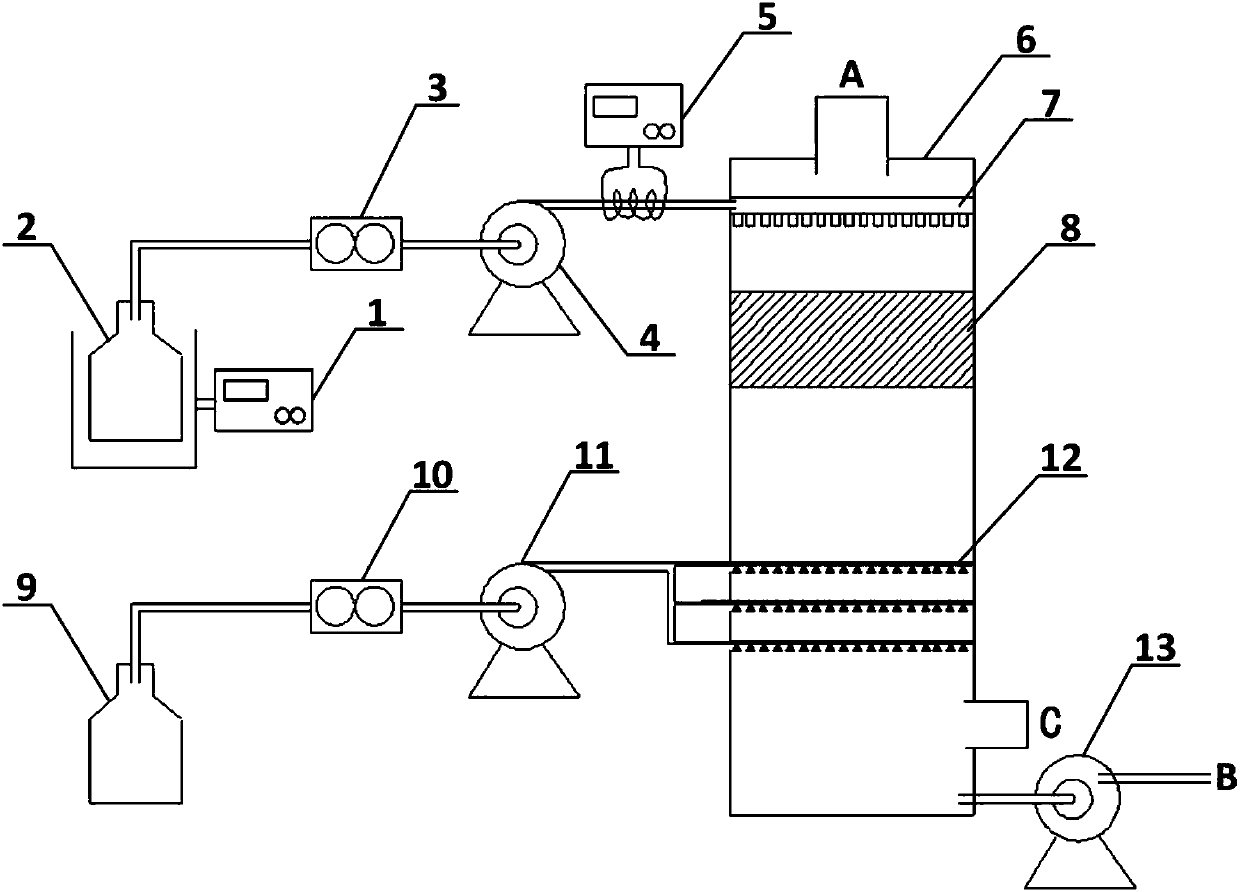

Method used

Image

Examples

Embodiment 1

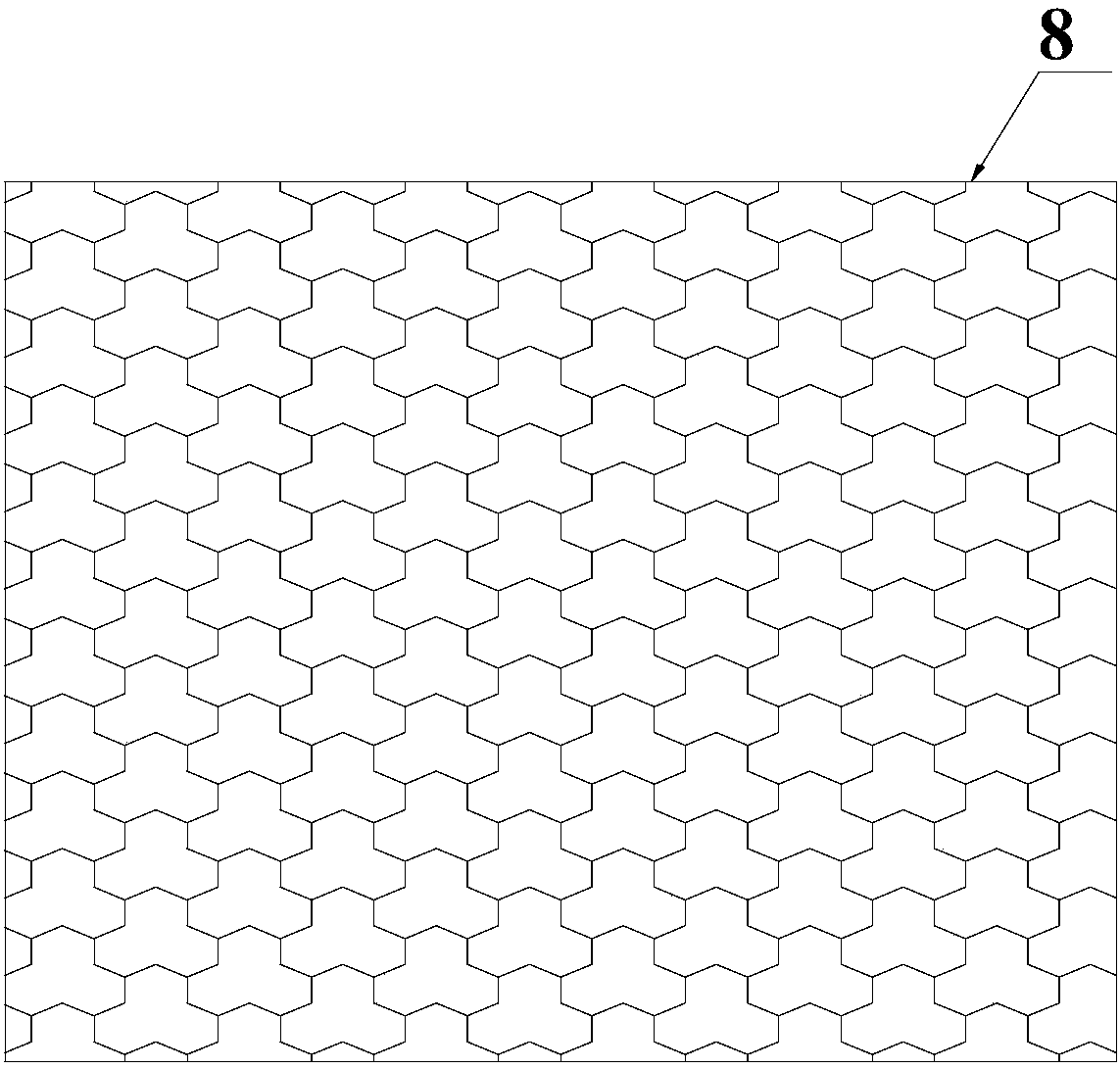

[0047] h 2 o 2 Mass fraction is 3% H in the solution storage tank (2) 2 o 2 The solution is measured by the No. 1 flow meter (3), and is transferred by the No. 1 transfer pump (4) and flows through the heating device (5) to change into H 2 o 2 steam, h 2 o 2 The steam passes through the grid (7) and mixes with the dedusted flue gas entering from the flue gas inlet A of the reaction tower (6). The NO content in the flue gas is 600ppm, the inlet flue temperature is 180°C, and the mixed gas passes through the coating with 1% Fe-TiO 2 The corrugated plate (8) of the catalyst generates acid gas containing nitrous acid and nitric acid, wherein the space velocity ratio is 60000h -1 . The lye in the lye storage tank 9 is metered by the No. 2 flowmeter (10), and is transported to the spraying device (12) by the No. 2 delivery pump (11) to form alkaline atomized droplets, and the alkaline atomized droplets The acid gas is washed to generate nitrite and nitrate solut...

Embodiment 2

[0049] When using the method of Example 1 to carry out denitrification, wherein, the concentration of nitric oxide in the treated flue gas is 750ppm, and the catalyst is 2% Fe-TiO 2 , the airspeed ratio is 60000h -1 , the mass fraction of hydrogen peroxide is 4%, the molar ratio of hydrogen peroxide to nitric oxide is 12:1, the inlet smoke temperature is 200°C, the oxidized acid gas is absorbed by lye spray, and the denitrification efficiency reaches 92%. The waste liquid at the bottom of the tower is detected by ion chromatography, and the molar ratio of nitrate and nitrite is 7.4:1.

Embodiment 3

[0051] When using the method of Example 1 to carry out denitrification, wherein, the concentration of nitric oxide in the treated flue gas is 550ppm, and the catalyst is 3% Fe-TiO 2 , the airspeed ratio is 60000h -1 , the mass fraction of hydrogen peroxide is 4%, the molar ratio of hydrogen peroxide to nitric oxide is 16:1, the inlet smoke temperature is 220°C, the oxidized acid gas is absorbed by lye spray, and the denitrification efficiency reaches 91%. The waste liquid at the bottom of the tower is detected by ion chromatography, and the molar ratio of nitrate and nitrite is 6.9:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com