Fluorinated process tail gas purification treatment system

A purification treatment and chemical process technology, which is applied in the field of uranium conversion, can solve the problems of difficulty and disadvantage of fluorine gas recycling and reuse, and achieve the effects of easy control mode, simple operation and simple system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

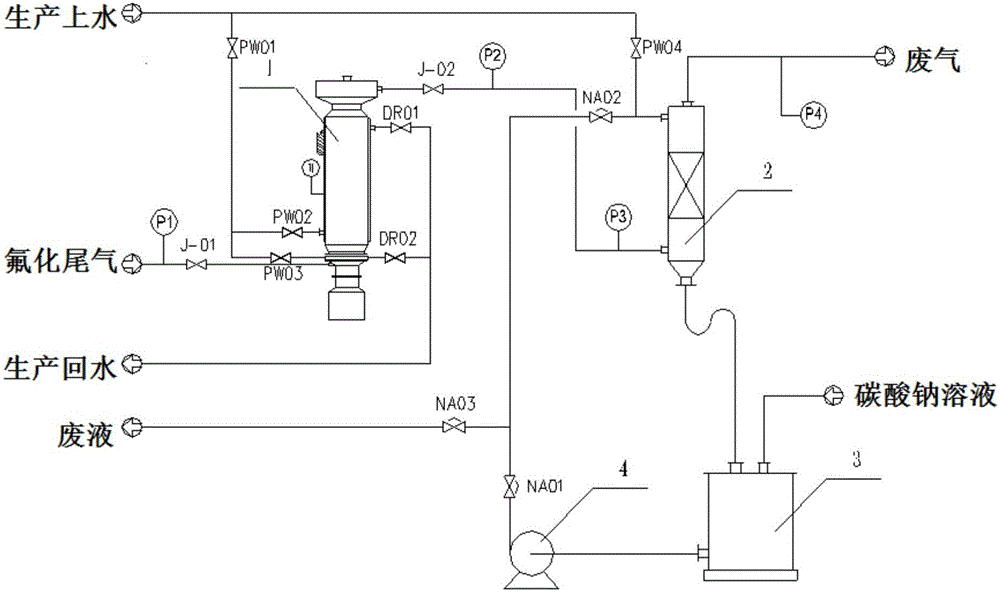

[0069] According to the technical route of charcoal adsorption-alkali leaching, the present invention develops a fluorinated tail gas purification treatment system. The specific implementation is as follows:

[0070] 1) Established a fluorinated tail gas purification treatment system. The device is composed of a vertical carbon reactor, a packed leaching tower, a lye tank, a shielded pump, monitoring instruments and related pipelines.

[0071] 2) Start the system.

[0072] (1) Fill the charcoal reactor with charcoal. Open the charcoal inlet of the charcoal reactor, and pour (200-250) kg of dry bagged charcoal into the charcoal reactor.

[0073] (2) Turn on the carbon reactor cooling system. Open the valves PW01, PW02, PW03, DR01, DR02, and ensure that the cooling water is unimpeded.

[0074] (3) Add eluent to the lye tank. Inject (1200-1500)mm sodium carbonate solution with a concentration of (3-5)% into the lye tank.

[0075] (4) Open the lye circulation system. Open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com