Environment-friendly splashing derusting device

An environmentally friendly, rust remover technology, which is applied in the fields of combined devices, gas treatment, membrane technology, etc., can solve the problems of increased floor space, inconvenient operation and management, large floor space and space, etc., to reduce labor intensity, The effect of avoiding the phenomenon of excessive discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing, but should not be interpreted as that the scope of the subject matter of the present invention is limited to following embodiment, under the situation of not departing from above-mentioned technical idea of the present invention, all according to the common technical knowledge of this field and Various modifications, substitutions and alterations made by conventional means are included within the scope of the present invention.

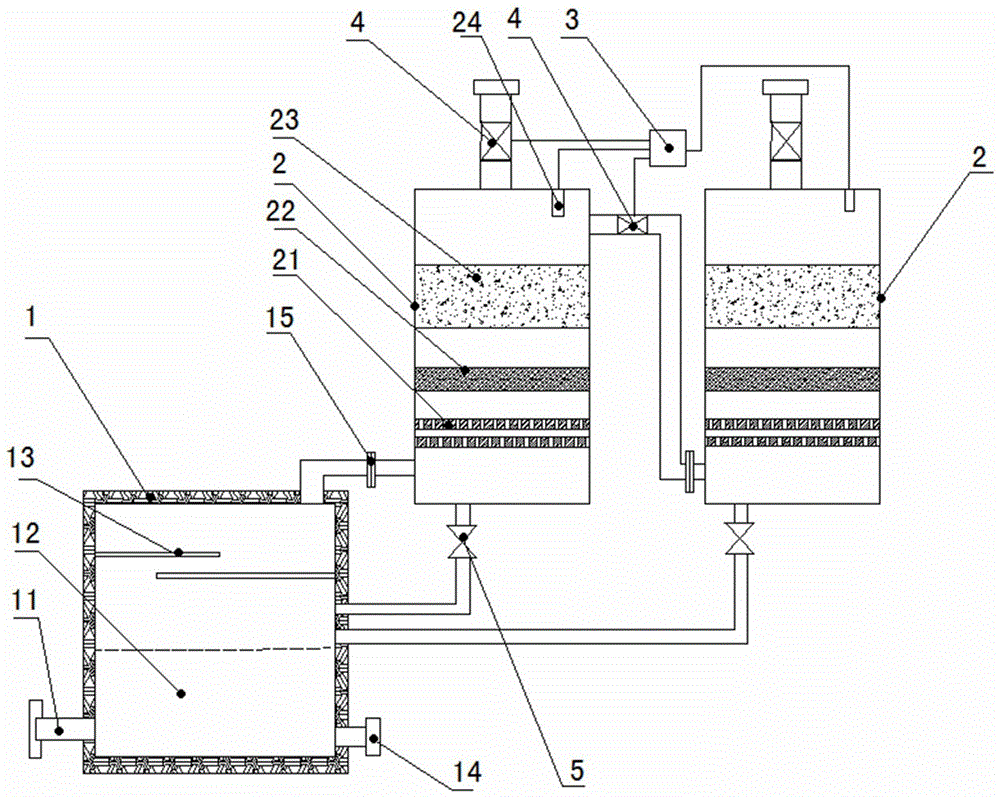

[0015] Such as figure 1 As shown, an environment-friendly splash derusting device is mainly composed of an isolation tank 1, a splash derusting device 2, and a control device 3, and is characterized in that the lower part of the isolation tank 1 is provided with an air inlet 11, The discharge port 14, the air inlet 11 are connected with the sandblasting machine, the bottom of the isolation tank 1 is equipped with a solvent 12, the top of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com