Permanent magnet motor position-sensorless rotor position determining method and device

A permanent magnet motor, sensor rotor technology, applied in the field of power electronics, can solve the problem of large error in rotor position determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

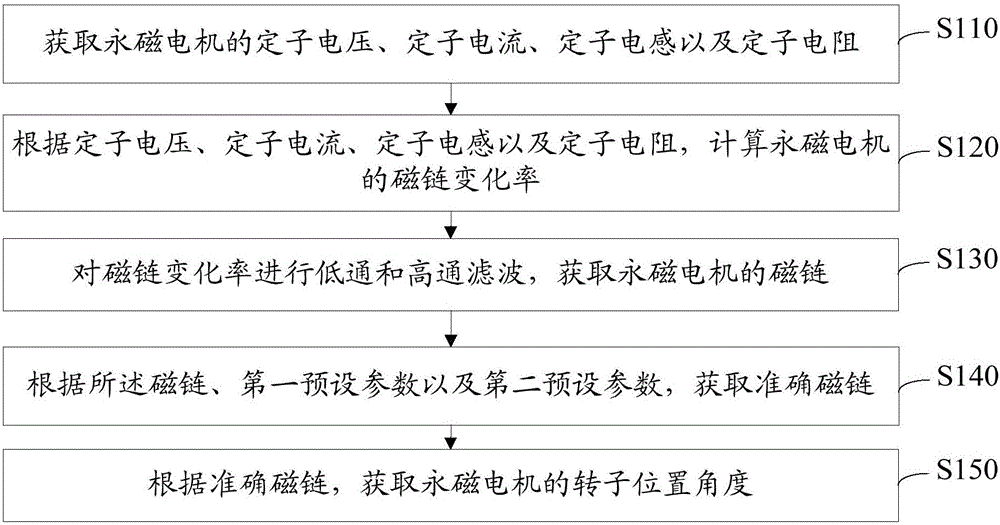

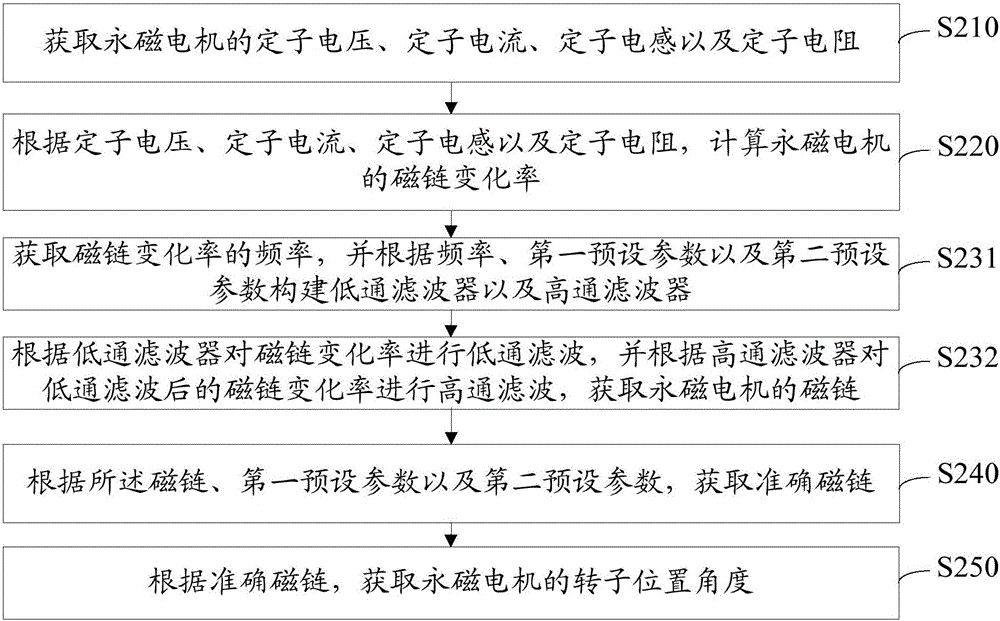

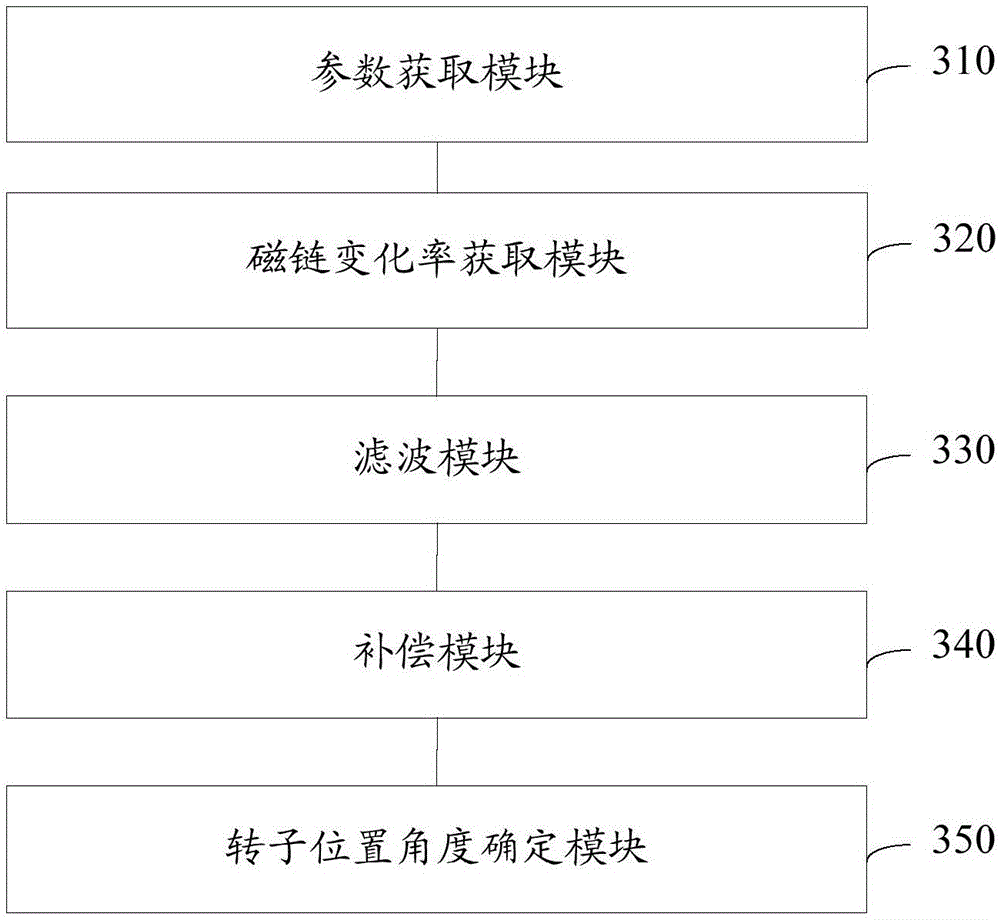

[0023] see figure 1 , providing a method for determining the position of a permanent magnet motor without position sensing rotor in an embodiment, comprising the following steps:

[0024] S110: Obtain the stator voltage, stator current, stator inductance and stator resistance of the permanent magnet motor.

[0025] The permanent magnet motor includes a stator and a rotor. The stator includes a stator core and a stator winding for setting the iron core. The rotor is usually composed of a shaft, a permanent magnet and a yoke. The main function is to generate sufficient magnetic induction in the air gap of the motor. It interacts with the energized stator windings to generate torque to drive itself.

[0026] Each permanent magnet motor has its corresponding parameters and values corresponding to the parameters. For example, the stator inductance and stator resistance of the permanent magnet motor. Initially, the values corresponding to the stator inductance and stator resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com