Non-contact infrared radiation system

A non-contact, infrared radiation technology, applied in the field of non-contact infrared radiation systems, can solve the problems of no ignition, poor sealing of the ignition pin, and low gas volume, so as to improve power and efficiency, overcome thermal fracture, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

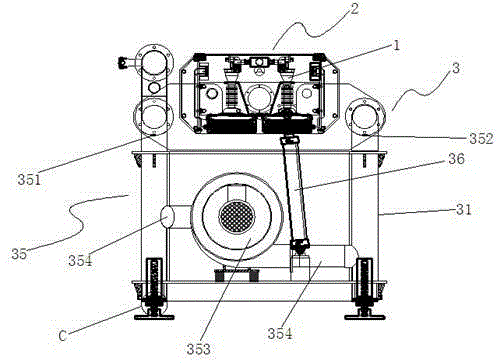

[0042] A non-contact infrared radiation system includes a non-contact infrared emitter 1 , an outer box 2 and a support mechanism 3 . The support mechanism 3 includes a frame body 31, a combustion air blower 32, a cooling blower 33, a proportional valve 34, a circulating air duct system 35 and a jacking cylinder 36; the combustion air blower 32, the cooling air blower 33 and the outer box body 2 are fixed on the frame body 31 superior.

[0043] The outer box body 2 includes a sealed bin 21, a cooling bin 22 and a combustion bin 23; the sealed bin 21 and the cooling bin 22 are separated by an upper partition 24; the cooling bin 22 and the combustion bin 23 are separated by a lower partition 25 The non-contact infrared emitter 1 includes a mixing part 11, a compression part 12 and a combustion part 13, the upper end of the compression part 12 is connected to the mixing part 11, and the lower end is connected to the combustion part 13; the mixing part 11 is located in the sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com