Super high-rise double tower building steel structure corridor assembling method

An assembly method and super high-rise technology, which are applied in building construction, construction, and construction material processing, etc., can solve the problems of inconvenient assembly method of steel structure corridors, waste of reinforcement materials, and increased safety risks, so as to reduce the project construction period. and project cost, improve assembly efficiency, and improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The super high-rise double-tower steel structure corridor assembly method of the present invention comprises the following steps:

[0033] a. Install hydraulic lifting device

[0034] A number of hydraulic lifting devices are installed at the positions of the main trusses of the predetermined steel structure corridors on the corresponding facades of the twin towers. The hydraulic lifting devices are arranged in a straight line. The hydraulic lifting devices of the twin towers correspond to each other and are centralized by the lifting control system Control; one end of the lifting wire rope 6 of the hydraulic lifting device is connected with the lifting rod of the hydraulic lifting device, and the other end hangs down to the ground.

[0035] b. Installation of assembly platform

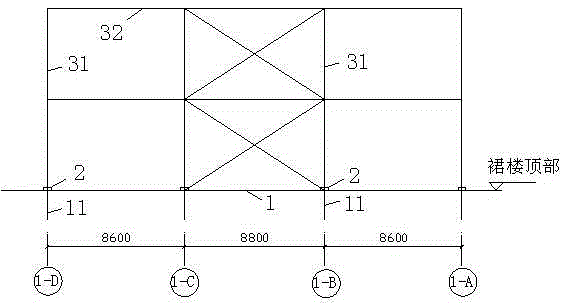

[0036] Between the bottom of the twin towers is a podium of ancillary structure, which is a reinforced concrete frame structure.

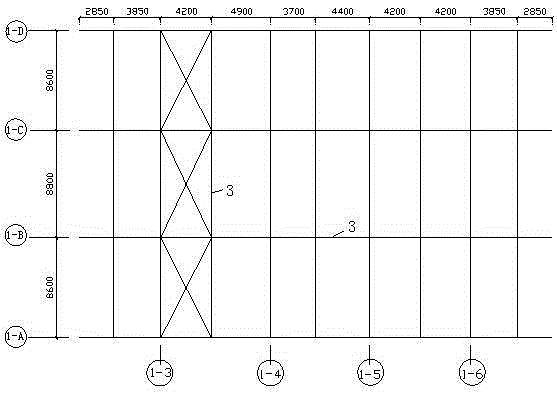

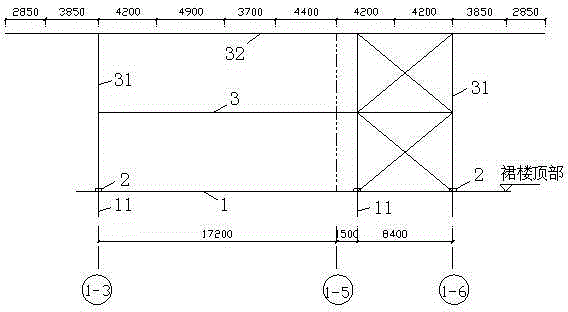

[0037] see now Figure 1-3 , figure 1 It is a plan view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com