Mechanical electric baking appliance and heating control method of same

A technology of heating control and heating control circuit, which is applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of surface coating electrical components damage, food easily scorched and burnt, and shortened service life, etc. Achieve the effect of shortening cooking time, low circuit design and maintenance costs, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

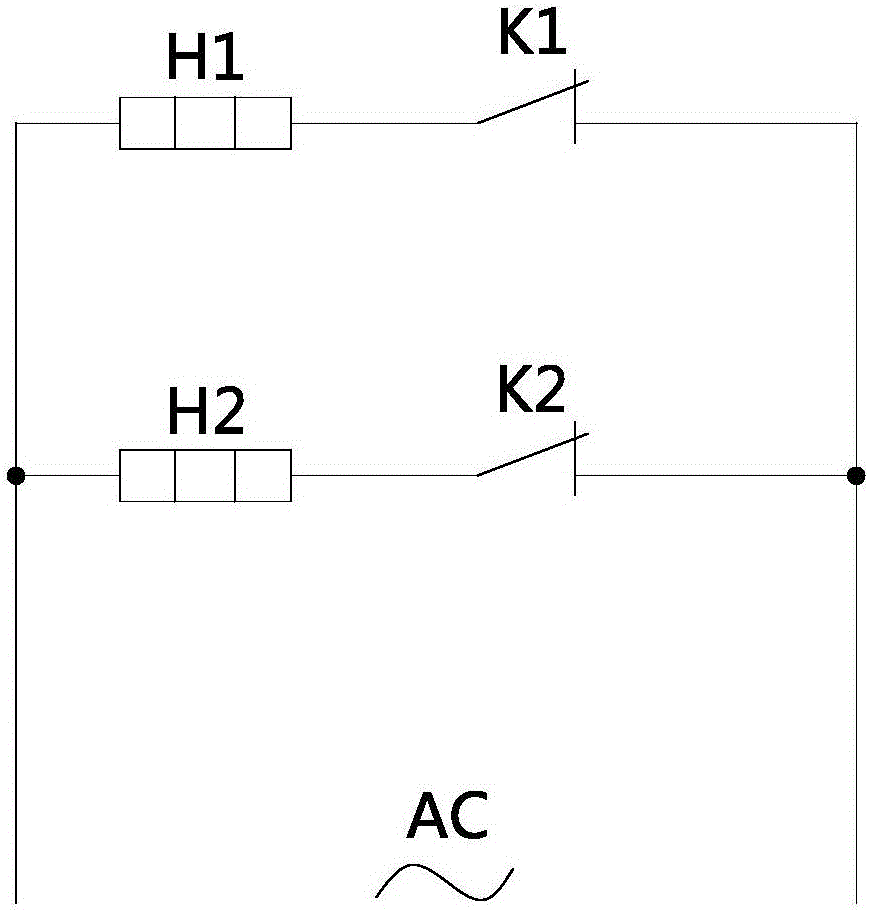

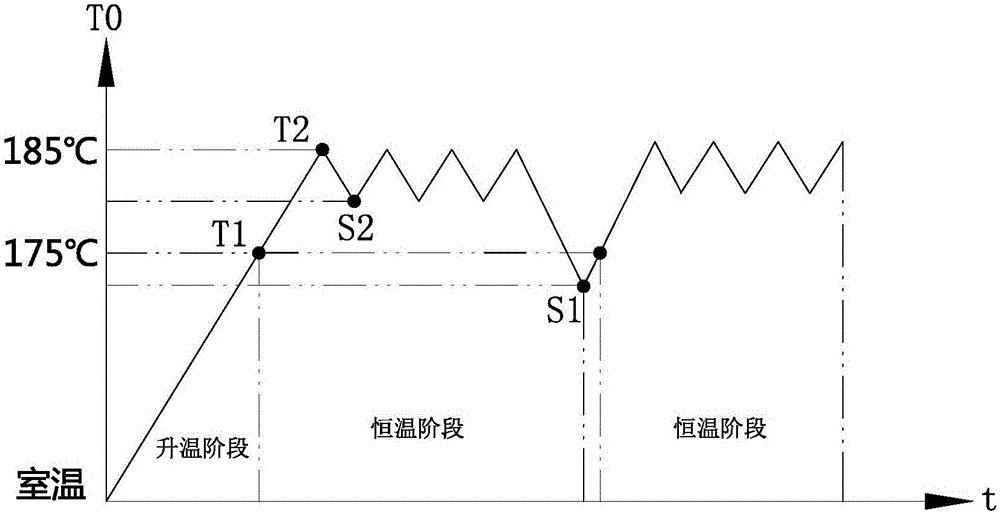

[0034] Reference figure 1 , 2 , The heating control method of the mechanical electric grill of the present invention, the heating control circuit of the electric grill includes a first heating branch with a heater H1, a thermostat K1 that controls the on and off of the first heating branch, and a heater H2 The second heating branch and the thermostat K2 that controls the on and off of the second heating branch. Both the thermostat K1 and the thermostat K2 are normally closed thermostats. The disconnection temperature T1 of the thermostat K1 is less than the temperature The switch-off temperature T2 of the controller K2, the heating control method includes the heating stage and the constant temperature stage:

[0035] In the heating stage, the heater H1 and the heater H2 start heating and heating at the same time, and when the actual temperature T0 rises to the cut-off temperature T1, the first heating branch is cut off and enters the constant temperature stage;

[0036] In the cons...

Embodiment 2

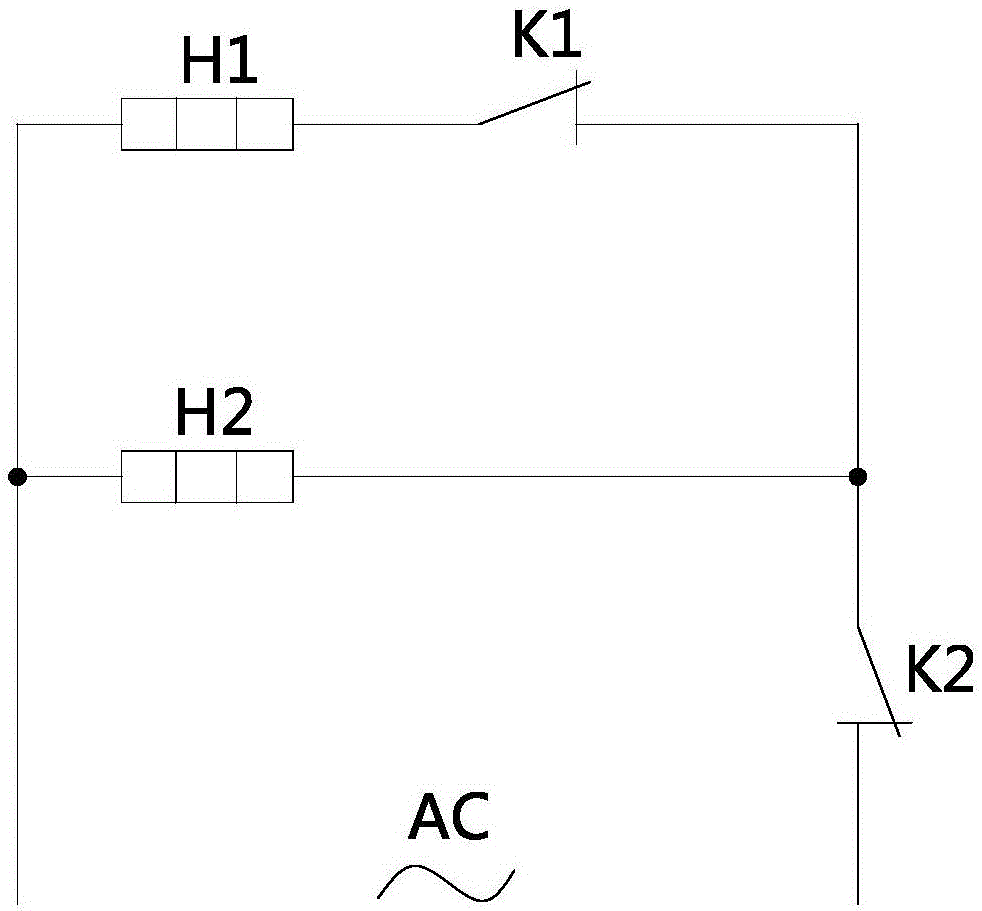

[0049] Reference image 3 The difference between this embodiment and the first embodiment is that the thermostat K1 is arranged in the first heating branch and is connected in series with the heater H1, and the first heating branch and the second heating branch are connected in parallel and then connected in series with the thermostat K2 , And then connect to the AC power terminal. In the circuit designed in this way, the thermostat K2 is equivalent to the main switch of the circuit. As long as the thermostat K2 is disconnected, even if the thermostat K1 is closed, the heater H1 will not work, and the safety is better.

[0050] According to the inventive idea of the present invention, those skilled in the art can easily add one or more heating branches according to specific needs. For example, the heating control circuit further includes a third heating branch with a heater H3 and the temperature controller K3 is normally closed Type thermostat, the disconnect temperature T2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com