Device And Method For Storing And Mixing Bone Cement

A technology of bone cement and mixing cavity, which is applied in the fields of storing initial components of bone cement, a device for mixing the initial components, and a device for mixing bone cement, which can solve the problems of sterilizing the inner cavity and not being suitable for long-term storage of monomer fluids, etc. To achieve the effect of avoiding complex transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

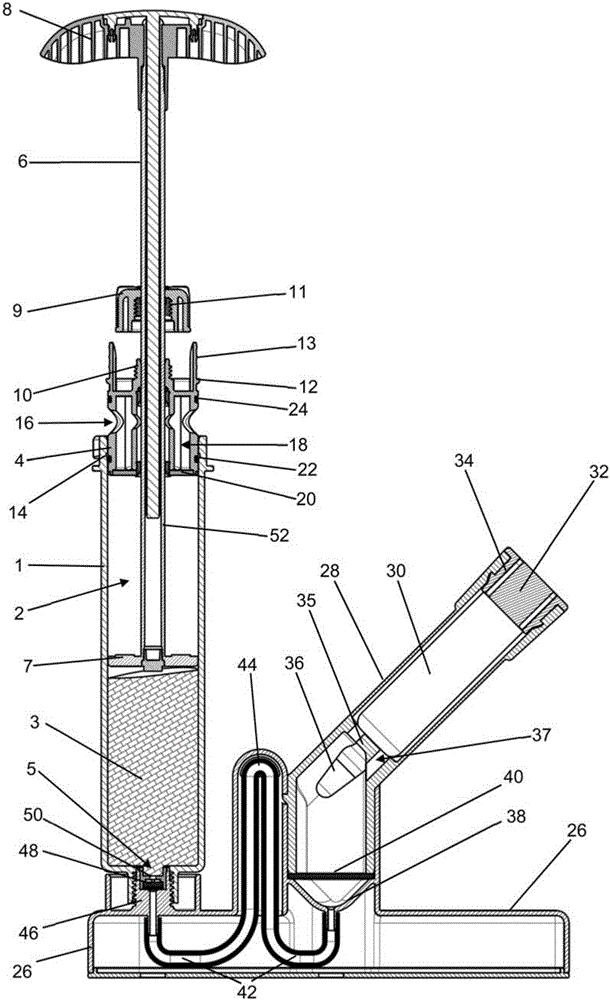

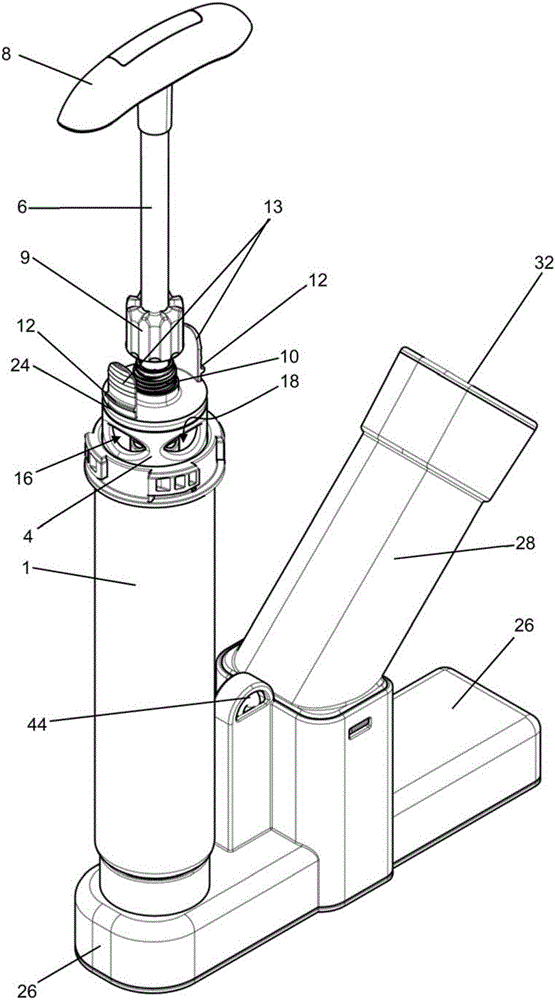

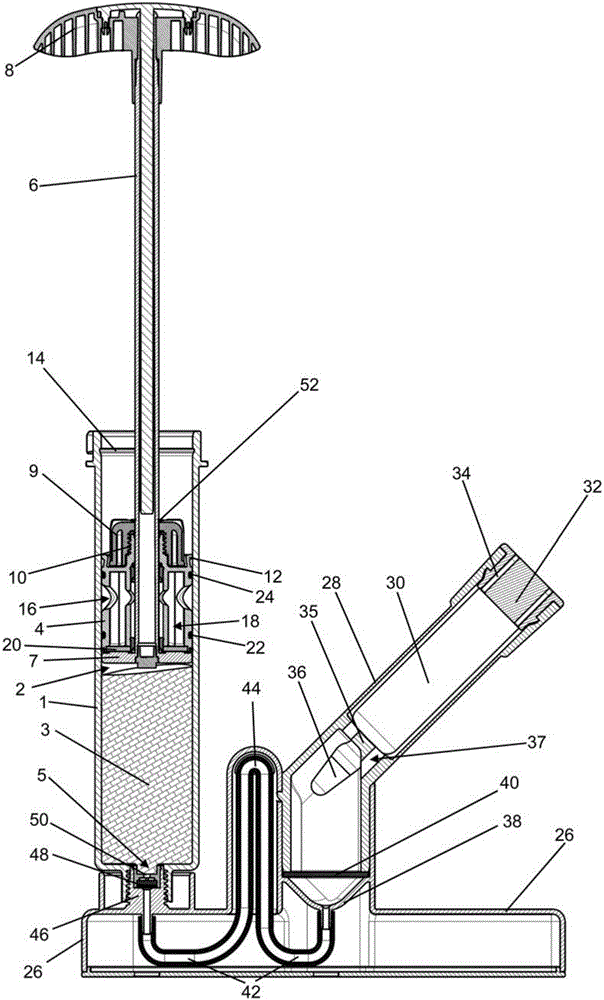

[0137] figure 1 and figure 2 In section view ( figure 1 ) and side perspective ( figure 2 ) shows a first method according to the invention for mixing bone cement and for storing initial components of the bone cement. Figure 3 to Figure 5 Schematic cutaway showing alternative devices for mixing bone cement and for storing the initial components of the bone cement, where they are associated with figure 1 and figure 2 The exemplary embodiment shown differs only in that the locking mechanism cannot be released from the outside by means of the actuating element 13 . Because the exemplary embodiments are highly similar, identical or similar parts in the figures are labeled with the same reference numerals, even though the parts may be different. see Figure 3 to Figure 5 To describe the sequence of the method of the present invention. However, this method can also be used as figure 1 or figure 2 The arrangement shown is conveniently implemented in the same manner, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com