Water-cooling valve stem structure of 1500-DEG C superhigh temperature valve

An ultra-high temperature, valve stem technology, used in valve heating/cooling devices, valve details, valve devices, etc., can solve the problem that the valve outlet medium fails to meet the test requirements, the medium heat loss is large, and the properties of non-metallic materials cannot be Meet the problems of rapid cooling, rapid heating and high pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A water-cooled valve stem structure for a 1500°C ultra-high temperature valve includes a valve stem, the valve stem is a variable-diameter structure, and a single-circulation water-cooling structure is arranged on the valve stem.

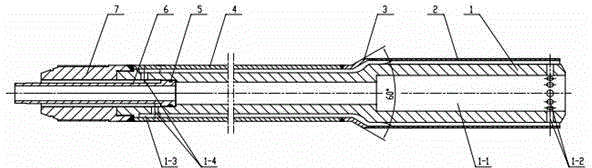

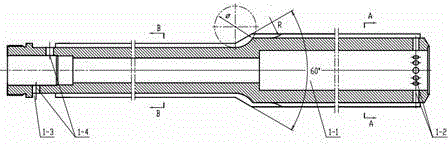

[0022] like figure 1 As shown, the valve stem is welded by the valve stem body 1 and the valve stem joint 7, and the outside of the valve stem body 1 is composed of two parts with a large diameter section and a small diameter section connected by a transition section to form a reduced diameter structure.

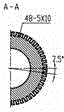

[0023] After the valve stem main body 1 and the valve stem joint 7 are fixed, there is a first through cavity 1-1 inside; the wall thickness of the end of the large diameter section of the valve stem main body 1 is processed with a first hole 1- 2. The first hole 1-2 communicates with the first cavity 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com