Hydraulically controlled pivot type water injection pump capable of achieving automatic hydraulic pressure adjustment

A hydraulic automatic and pilot-operated technology, applied in variable capacity pump components, liquid fuel engines, liquid variable capacity machines, etc., can solve problems such as increased power consumption, insufficient system pressure, energy waste, etc., to reduce input pressure Poor requirements, solve incomplete commutation, improve the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

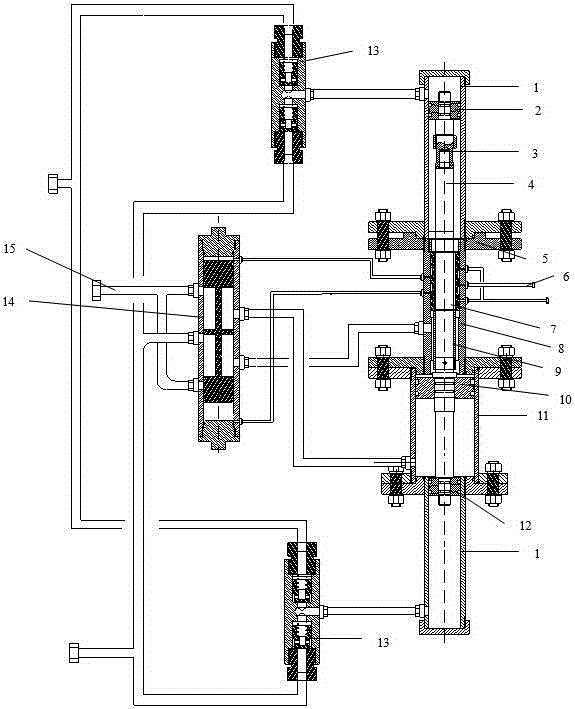

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0019] according to figure 1 , the hydraulic control pilot hydraulic automatic pressure-regulating water injection pump, including the front booster cylinder, reversing working cylinder 8, low-pressure working cylinder 11, and rear booster cylinder connected sequentially from front to back. All the above cylinders pass through their respective manifolds. Connected to the main reversing valve 14, the reversing working cylinder is also connected to the pilot valve control manifold 6, and the pilot valve control manifold is connected to the main reversing valve 14, and the main reversing valve also passes its own high and low pressure The outlet is connected with the high and low pressure manifold 15. A front one-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com