Blade lock

A blade lock and blade technology, which is used in construction locks, cylinder marble locks, locks with turning keys, etc., can solve the problems of poor anti-technical opening, inconvenient use, and difficult operation, and achieve good anti-pick performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

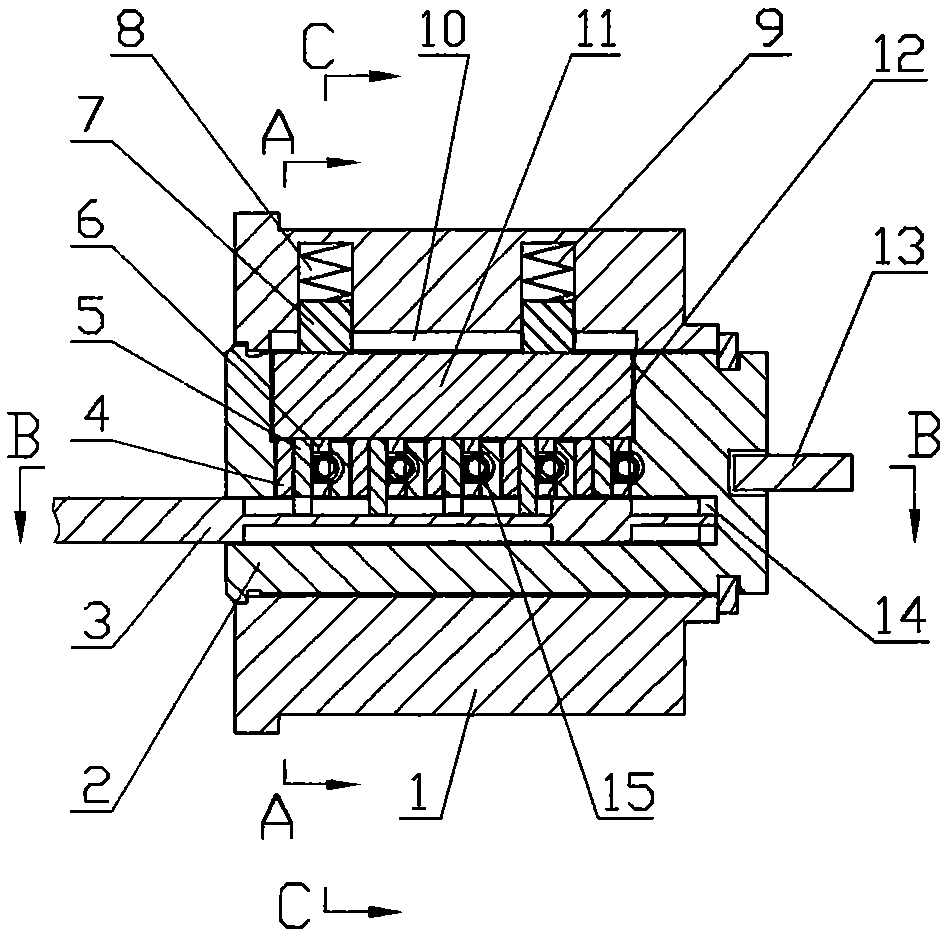

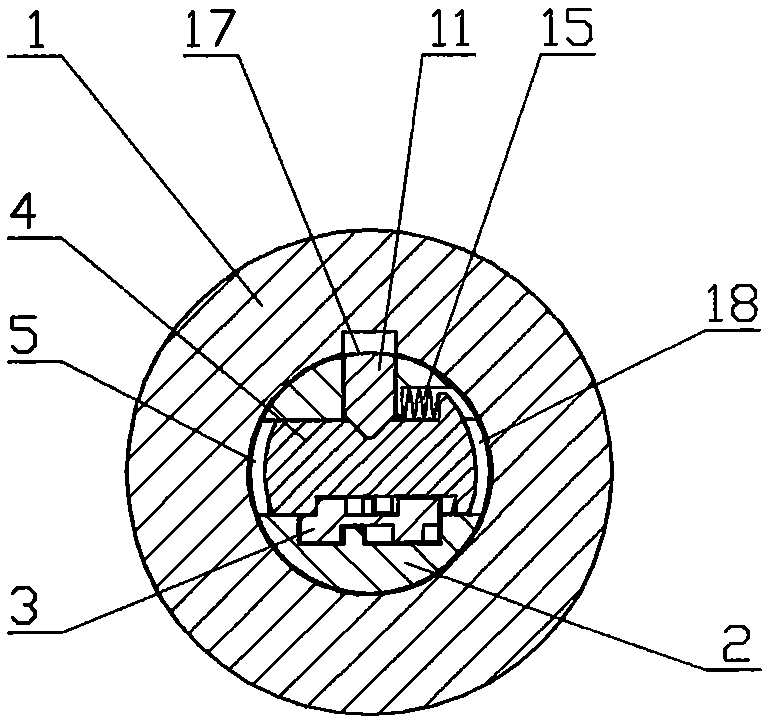

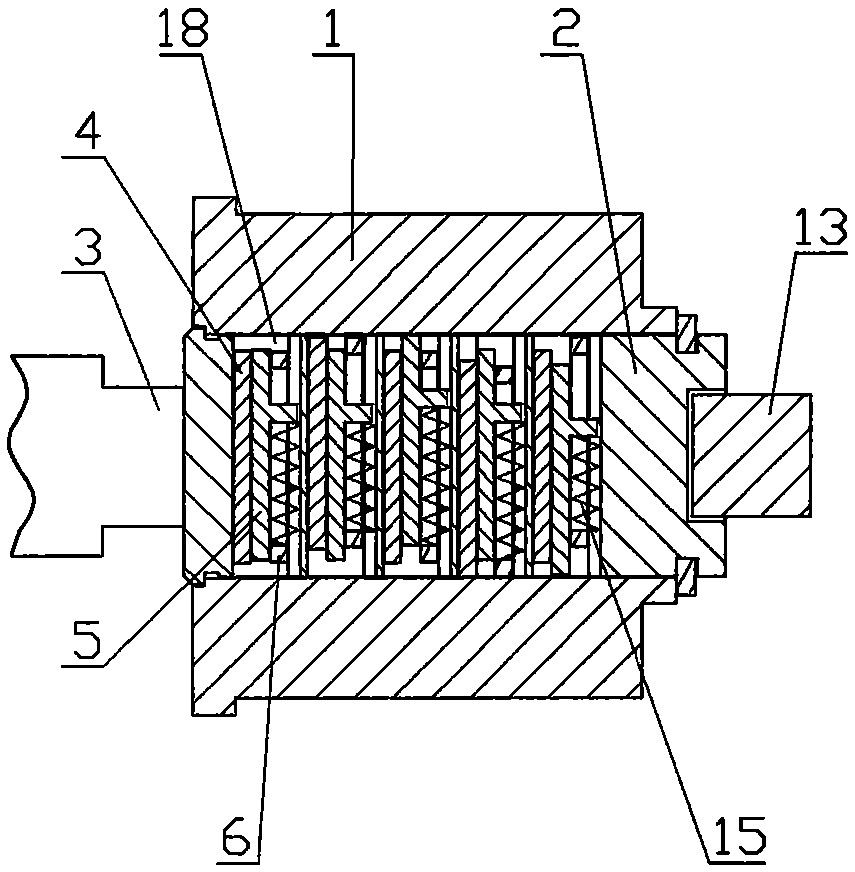

[0047] Figure 1-8 Shown is the first embodiment of a blade lock head of the present invention, including a lock body, a lock cylinder and a key. Several vane slots, the vane slots communicate with the keyholes, the keyholes pass through the bottom side of the vane slots, and each vane slot is provided with three front vanes, middle vanes and rear vanes stacked forward and backward along the axial direction of the lock cylinder, The leaf spring of the front blade is set on the upper side of the blade. The middle blade and the rear blade share a leaf spring. A leaf spring is installed between them, and there is a notch on the bottom side where each leaf intersects with the keyhole for the key to pass through. An inner milling flower groove B is provided on the upper side of the inline groove, an inner milling flower groove A is provided on the lower side of the inline groove, an outer milling flower groove C is set on the upper side of the key, and the front blade The notch i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com