A kind of high flow rate clean kettle filter element

A water purification pot and high flow rate technology, applied in filtration treatment, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve the problem of small water flow and purification speed, inconvenient disassembly and assembly of filter elements, and complicated filter element structure and other problems, to achieve the effect of reducing the contact area, reducing the filtration time, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

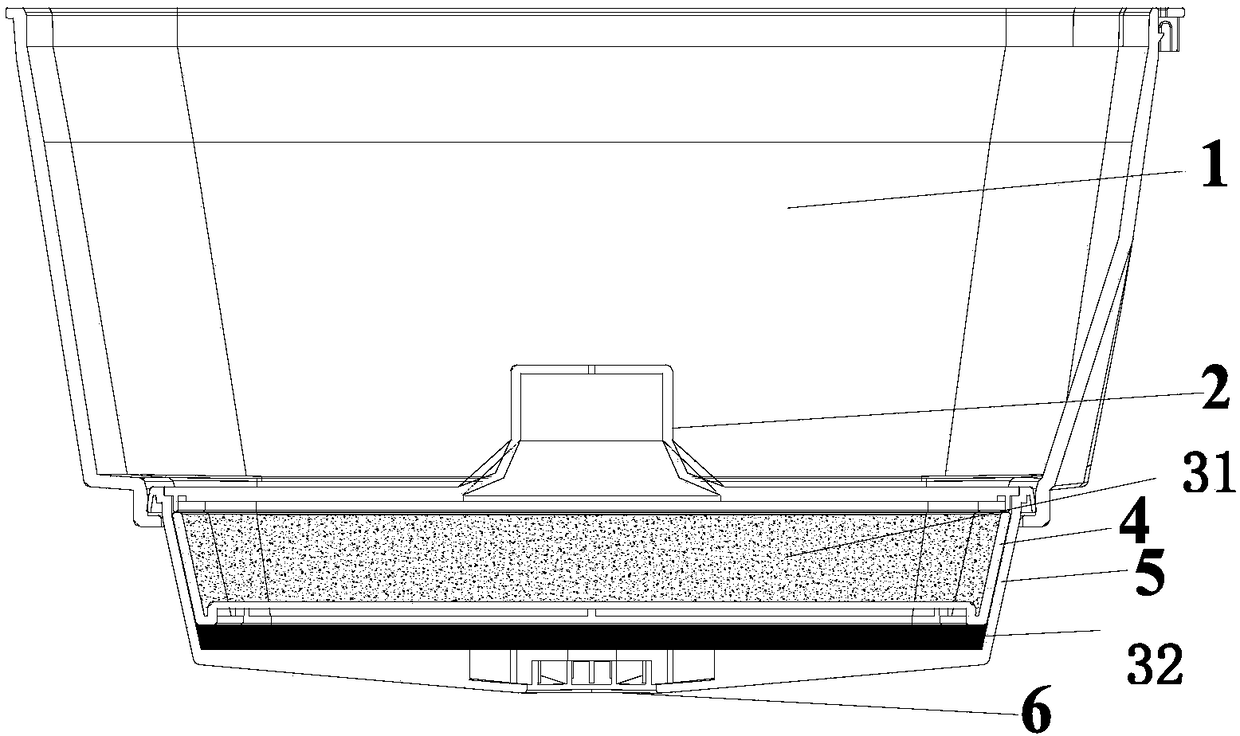

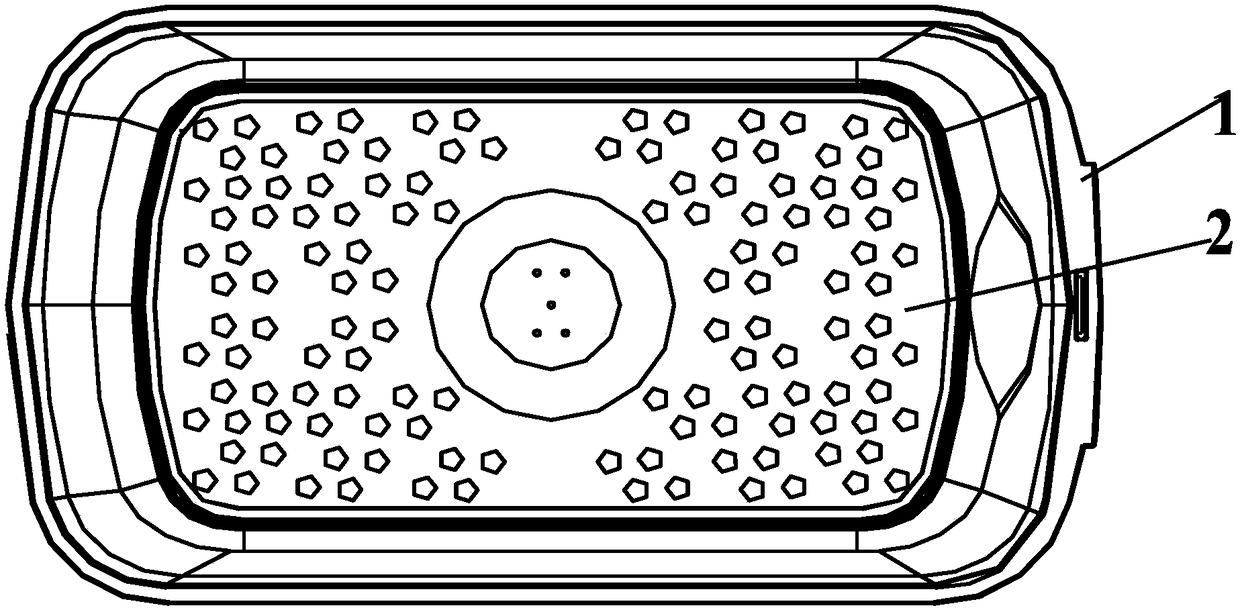

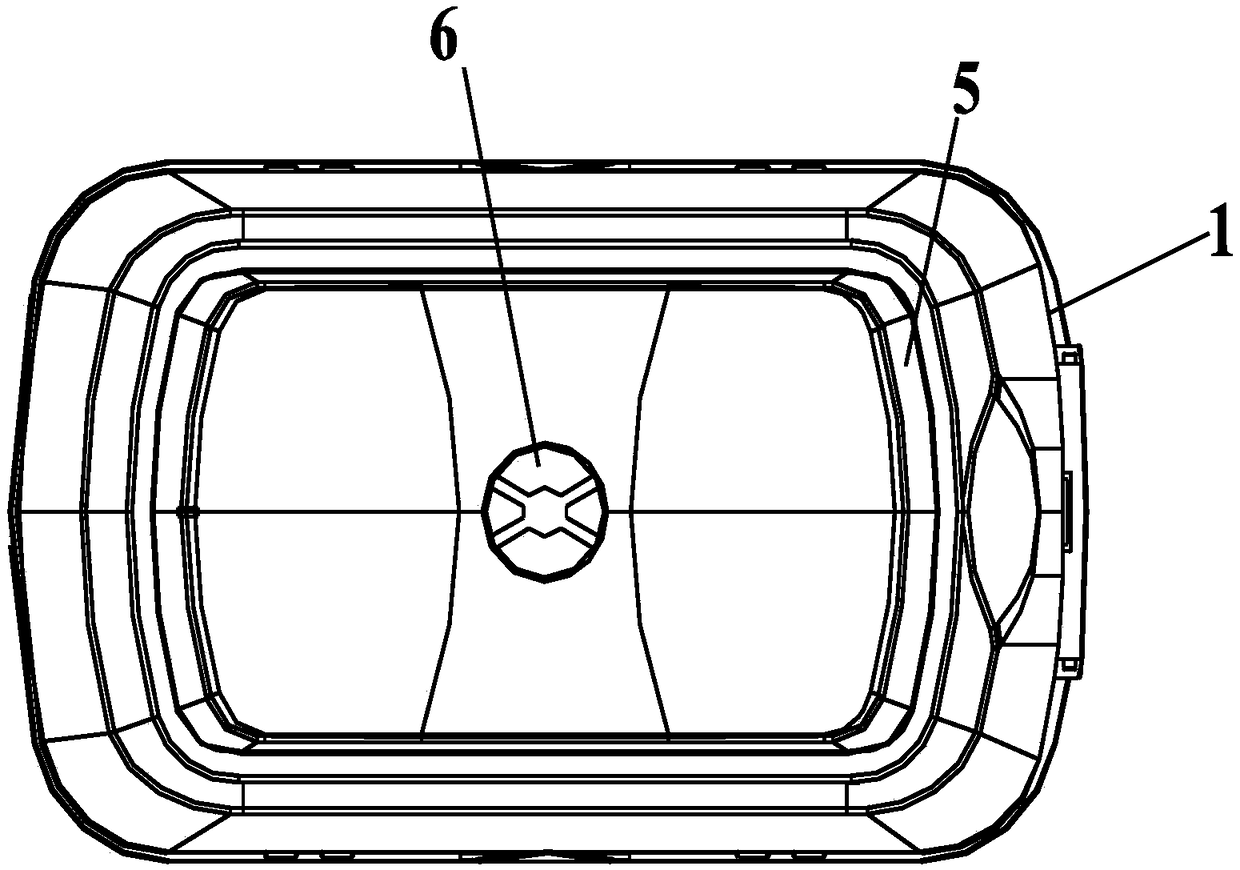

[0026] A high flow rate water purification kettle filter element, comprising a raw water storage unit 1, a water inlet unit 2, a filter unit 3, a filter element sealing unit 4, a filter element cylinder unit 5, and a water outlet unit 6. The lower edge of the raw water storage unit 1 is provided with There is a protrusion, which is used to hang the filter cylinder unit 5 on the kettle, a protrusion is arranged in the middle of the upper part of the water inlet unit 2, and a small hole is opened at the protrusion, and the water inlet unit 2 is provided with At the bottom of the raw water storage unit 1, the size of the filter element cylinder unit 5 matches the size of the water inlet unit 2, the filter unit 3 is arranged in the filter element cylinder unit 5, and the filter element extrudes The unit 4 is arranged in the filter unit 3 , and the water outlet unit 6 is arranged at the lower end of the filter cylinder unit 5 .

[0027] The upper protrusion of the water purificatio...

Embodiment 2

[0030] A high flow rate water purification kettle filter element, comprising a raw water storage unit 1, a water inlet unit 2, a filter unit 3, a filter element sealing unit 4, a filter element cylinder unit 5, and a water outlet unit 6. The lower edge of the raw water storage unit 1 is provided with There is a protrusion, which is used to hang the filter cylinder unit 5 on the kettle, a protrusion is arranged in the middle of the upper part of the water inlet unit 2, and a small hole is opened at the protrusion, and the water inlet unit 2 is provided with At the bottom of the raw water storage unit 1, the size of the filter element cylinder unit 5 matches the size of the water inlet unit 2, the filter unit 3 is arranged in the filter element cylinder unit 5, and the filter element extrudes The unit 4 is arranged in the filter unit 3 , and the water outlet unit 6 is arranged at the lower end of the filter cylinder unit 5 .

[0031]The upper protrusion of the water purification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com