Preparation method of high-performance organic bentonite for oil-based drilling fluid

A technology of oil-based drilling fluid and sodium-based bentonite, applied in drilling compositions, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor gelation and viscosity-increasing and cutting-lifting effects, and improve rheology Performance, rheology enhancement, performance enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

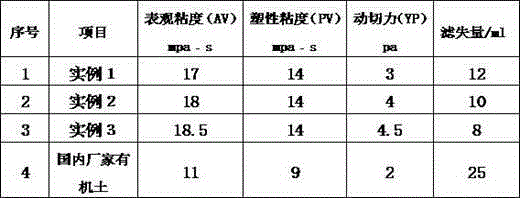

Examples

Embodiment 1

[0021] Disperse 50 parts of sodium base soil with an alkalinity coefficient of 3.5 into 700 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; 20 parts of dioctadecane Dimethyl benzyl ammonium chloride was dissolved in 300 parts of deionized water, and stirred evenly to make it a clear and transparent solution for later use. 10 parts of fatty acid polyoxyethylene ester RCOO (CH 2 CH 2 O) n H (n=9) was dissolved in 100 parts of deionized water and stirred evenly to make it a clear and transparent solution for later use. Under high-speed stirring, quickly add dioctadecyl dimethyl benzyl ammonium chloride solution to the suspension, react at 75°C for 1.5 hours, continue to add fatty acid polyoxyethylene ester solution, and stir for 1 hour . The product was cooled to room temperature, and the residual Cl in the product was repeatedly removed with deionized water - , filtered, and vacuum-drie...

Embodiment 2

[0023] Disperse 60 parts of sodium base soil with an alkalinity coefficient of 5 into 800 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; 22 parts of dioctadecane Dimethyl benzyl ammonium chloride was dissolved in 200 parts of ethanol, and stirred evenly to make it a clear and transparent solution for later use. 11 parts fatty acid polyoxyethylene ester RCOO (CH 2 CH 2 O)nH (n=12) was dissolved in 100 parts of deionized water and stirred evenly to make it a clear and transparent solution for later use. In the state of high-speed stirring, quickly add the dioctadecyldimethylbenzyl ammonium chloride solution to the suspension, react at 70°C for 1.5 hours, and continue to add fatty acid polyoxyethylene ester RCOO (CH 2 CH 2 O) nH (n=12) solution, stirred for 1 hour. The product was cooled to room temperature, and the residual Cl in the product was repeatedly removed with deionized water ...

Embodiment 3

[0025] Disperse 65 parts of sodium base soil with an alkalinity coefficient of 6 into 800 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; 24.8 parts of dioctadecane Dimethyl benzyl ammonium chloride was dissolved in 200 parts of ethanol, and stirred evenly to make it a clear and transparent solution for later use. 10.5 parts of fatty acid polyoxyethylene ester RCOO (CH 2 CH 2 O)nH (n=20) was dissolved in 100 parts of deionized water and stirred evenly to make it a clear and transparent solution for later use. In the state of high-speed stirring, quickly add the dioctadecyldimethylbenzyl ammonium chloride solution to the suspension, react at 70°C for 1.5 hours, and continue to add fatty acid polyoxyethylene ester RCOO (CH 2 CH 2 O) nH (n=20) solution, react for 1 hour. The product was cooled to room temperature, and the residual Cl in the product was repeatedly removed with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com