Paper feeding device and image forming device provided with same

A paper feeding and image technology, applied in the direction of object supply, transportation and packaging, thin material processing, etc., can solve the problems of uneven rollers, poor conveying, wrinkles, etc., and achieve the effect of avoiding speed difference and high-speed conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

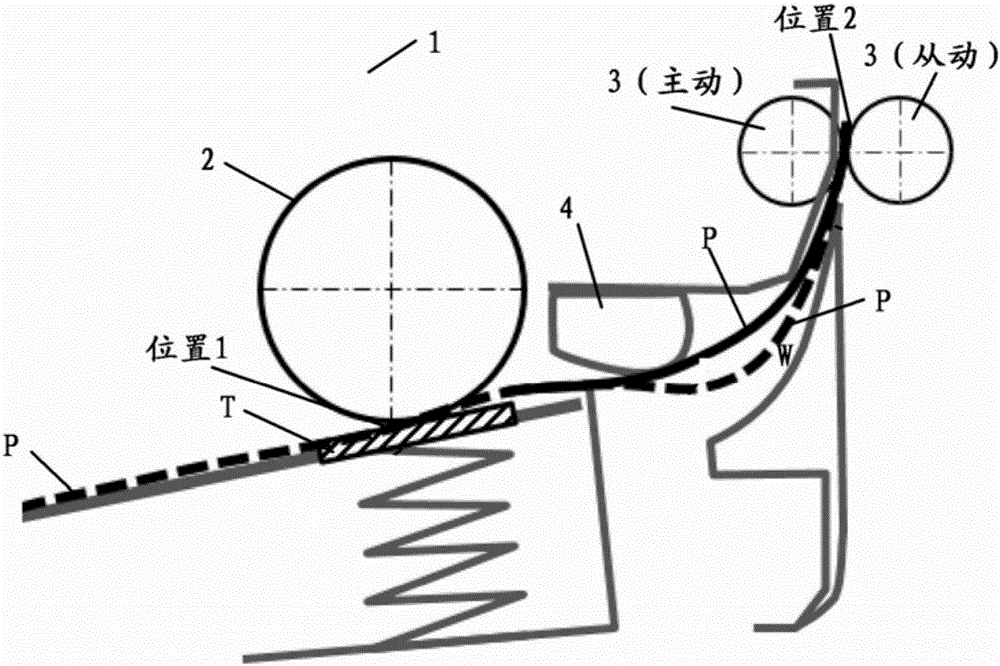

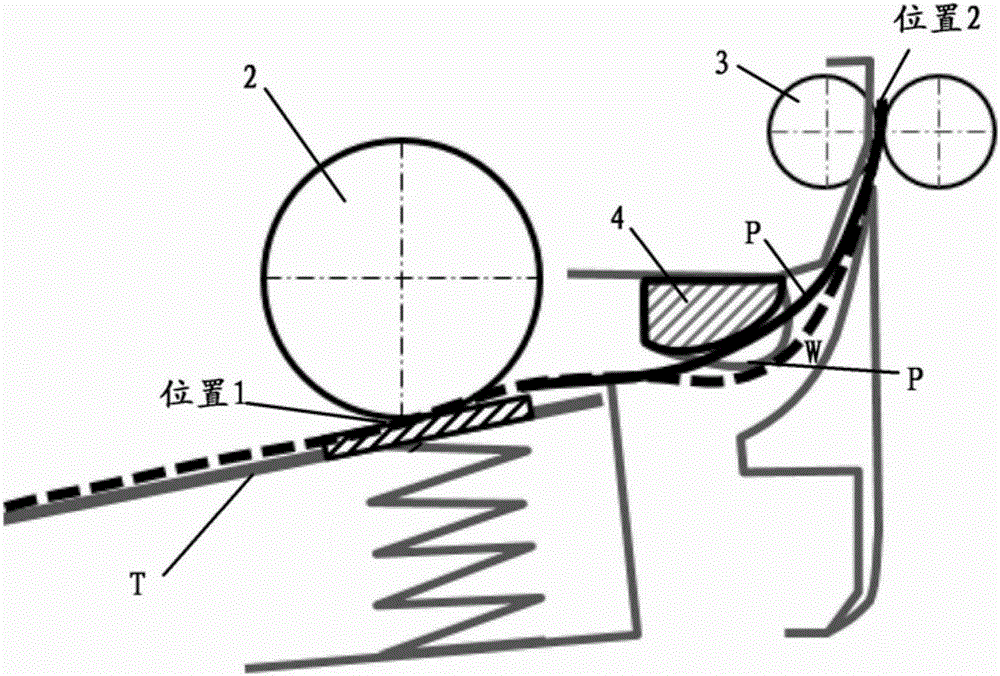

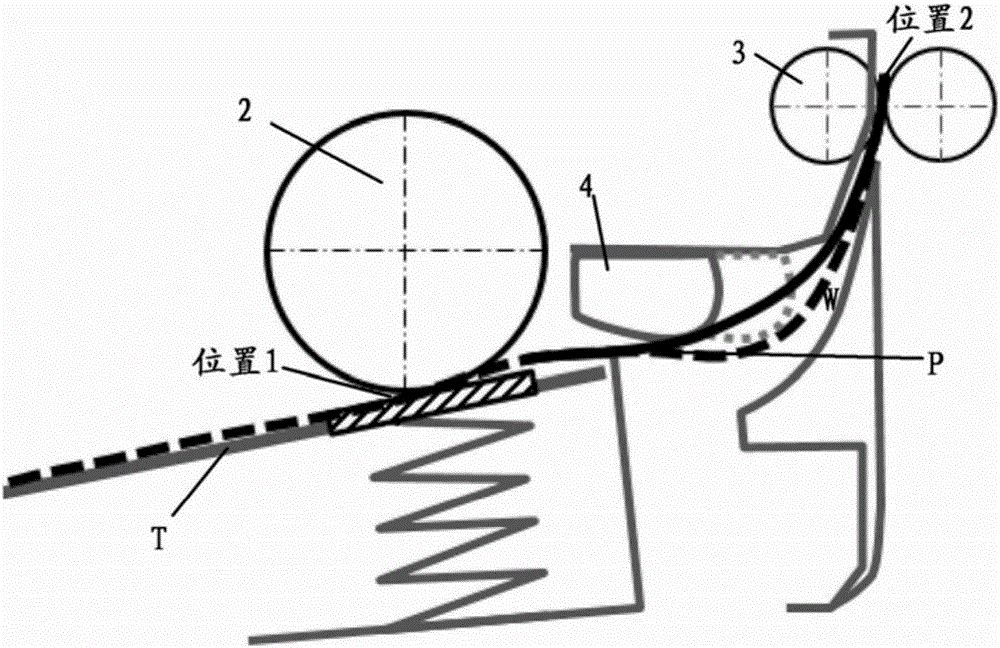

[0048] figure 1 A schematic diagram of the paper feeding device 1 of the present invention is shown. The paper feeding device 1 can be installed in devices such as printers, copiers, and composite machines, and is used for paper feeding.

[0049] Such as figure 1As shown, the paper feeding device 1 of the present invention picks up the paper P placed on the paper feeding tray T. The paper feeder 1 includes a pick-up roller 2 and a transport roller 3 positioned downstream in the paper transport direction relative to the pick-up roller 2 , and the paper P on the paper feed tray T is picked up one by one by the pick-up roller 2 . There is an elastic member such as a spring under the paper feeding tray T, which exerts force on the paper feeding tray T to ensure that the paper can contact the paper lifting roller 2 and be picked up.

[0050] During the paper feeding operation, the paper P is picked up from the paper feeding tray T by the paper lifting roller 2, and at position 1...

Embodiment approach 2

[0088] Figure 9 The paper feeding device 10 of Embodiment 2 is shown. In this embodiment, the difference from Embodiment 1 is that the shape of the pick-up roller 20 of the paper feeding device 10 is an incomplete circle or a cam shape. By making the paper lifting roller 20 form an incomplete circle or cam shape, its effective arc surface is no longer the entire circumference of the outer circumference of the paper lifting roller, but a section of arc surface (arc surface less than 360 degrees) . And, when the paper lifting roller 20 rotates from one end of the effective arc surface to the other end, the process of extracting a piece of paper from the paper feeding tray and conveying the paper P1 to the position of the conveying roller 30 is completed. Afterwards, since the extraction roller 20 is an incomplete circle, it turns to the area of the non-effective arc surface, so that it does not contact the paper P1, and the paper P1 is continuously conveyed by the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com