Device and method for recovering volatile organic chloride gas

A technology of volatile organic and organic chlorides, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of incomplete decomposition of organic waste gas, short service life of activated carbon, high operating cost, etc., and achieve good technical adaptability and market application prospects, good high humidity resistance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

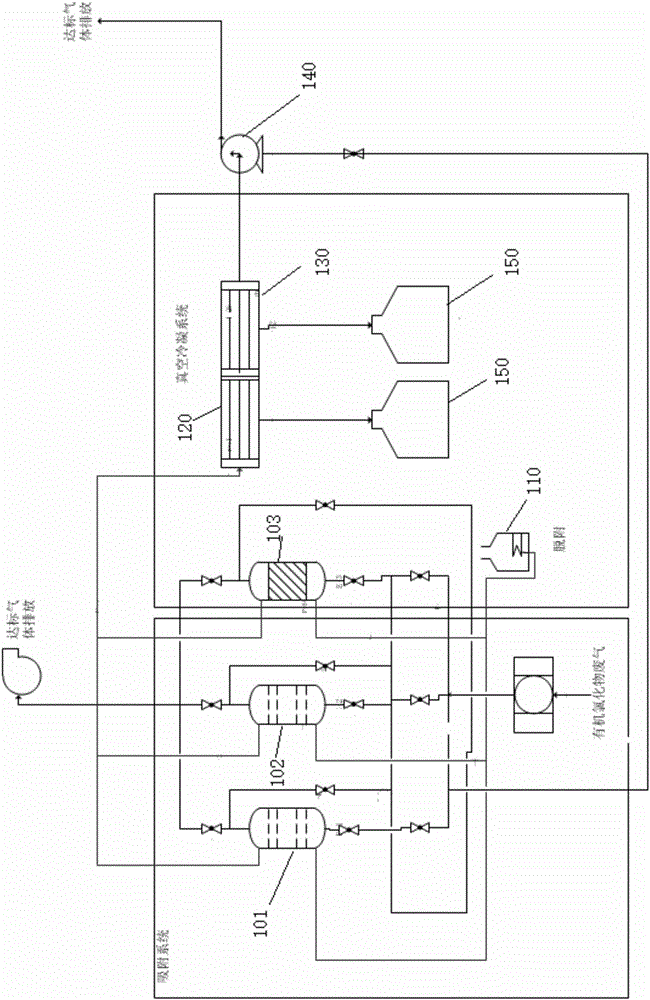

[0047] 683 liters of adsorption resin (commercially available) are packed in the adsorption tower, and this adsorption tower uses fluidized bed design, and three adsorption towers are all filled with resin in the same way. Will contain trichlorethylene concentration of 850mg / m 3 , The exhaust gas with a humidity of 40% first passes through a three-stage high-efficiency filter with a pore size of 200 mesh to remove paint residue or dust particles in the exhaust gas. The temperature of the exhaust gas is 30 degrees Celsius. Under the action of the fan, the exhaust gas passes through the first adsorption tower 101 for primary adsorption at an air volume of 50,000 cubic meters per hour, and the second adsorption tower 102 for secondary adsorption. The second adsorption tower 102 is monitored by PID The exhaust gas concentration at the outlet, the result shows that the exhaust gas emission concentration is 6mg / m 3 .Below the national standard, after 4 hours of continuous adsorptio...

Embodiment 2

[0049] 683 liters of adsorption resin (commercially available) are packed in the adsorption tower, and this adsorption tower uses fluidized bed design, and three adsorption towers are all filled with resin in the same way. Will contain trichlorethylene concentration 850mg / m 3 , The exhaust gas with a humidity of 80% first passes through a three-stage high-efficiency filter with a pore size of 200 mesh to remove paint residue or dust particles in the exhaust gas. The temperature of the exhaust gas is 25 degrees Celsius. Under the action of the fan, the exhaust gas passes through the first adsorption tower 101 for primary adsorption at an air volume of 40,000 cubic meters per hour, and the second adsorption tower 102 for secondary adsorption. The second adsorption tower 102 is monitored by PID The exhaust gas concentration at the outlet, the result shows that the exhaust gas emission concentration is 7.1mg / m 3 .Below the national standard, after 4 hours of continuous adsorption...

Embodiment 3

[0051] 683 liters of adsorption resin (commercially available) are packed in the adsorption tower, and this adsorption tower uses fluidized bed design, and three adsorption towers are all filled with resin in the same way. Will contain tetrachlorethylene concentration of 2000mg / m 3 , The organic waste gas with a humidity of 40% first passes through a three-stage high-efficiency filter with a pore size of 200 mesh to remove paint residue or dust particles in the waste gas. The temperature of the exhaust gas is 35 degrees Celsius. Under the action of the fan, the exhaust gas passes through the first adsorption tower 101 for primary adsorption) and the second adsorption tower 102 for secondary adsorption) with an air volume of 30,000 cubic meters per hour). The tail gas concentration at the outlet shows that the tail gas emission concentration is 7.6 mg / m3, which is lower than the national standard. After 4 hours of continuous adsorption treatment, the first adsorption tower 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com