Workshop scheduling agent group for intelligent manufacturing

A workshop scheduling and agent group technology, applied in the field of multi-agent systems, can solve problems such as the single structure of multi-agent systems and the inability to give full play to the distributed advantages of multi-agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

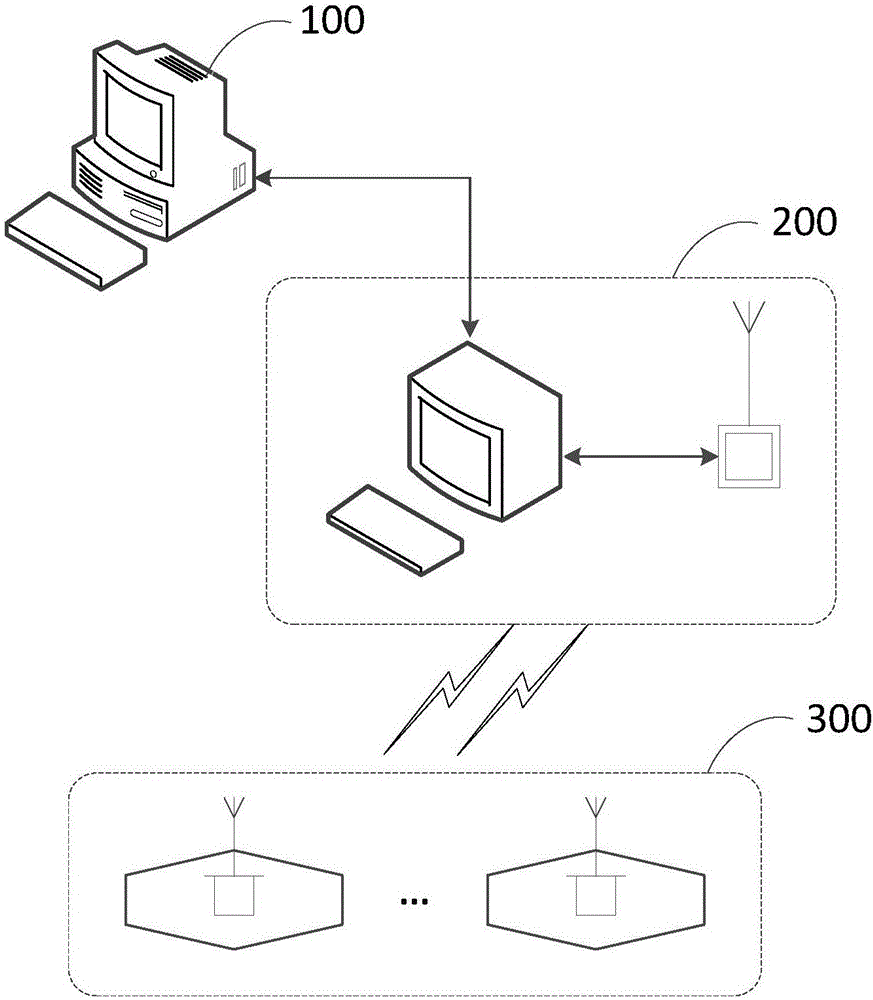

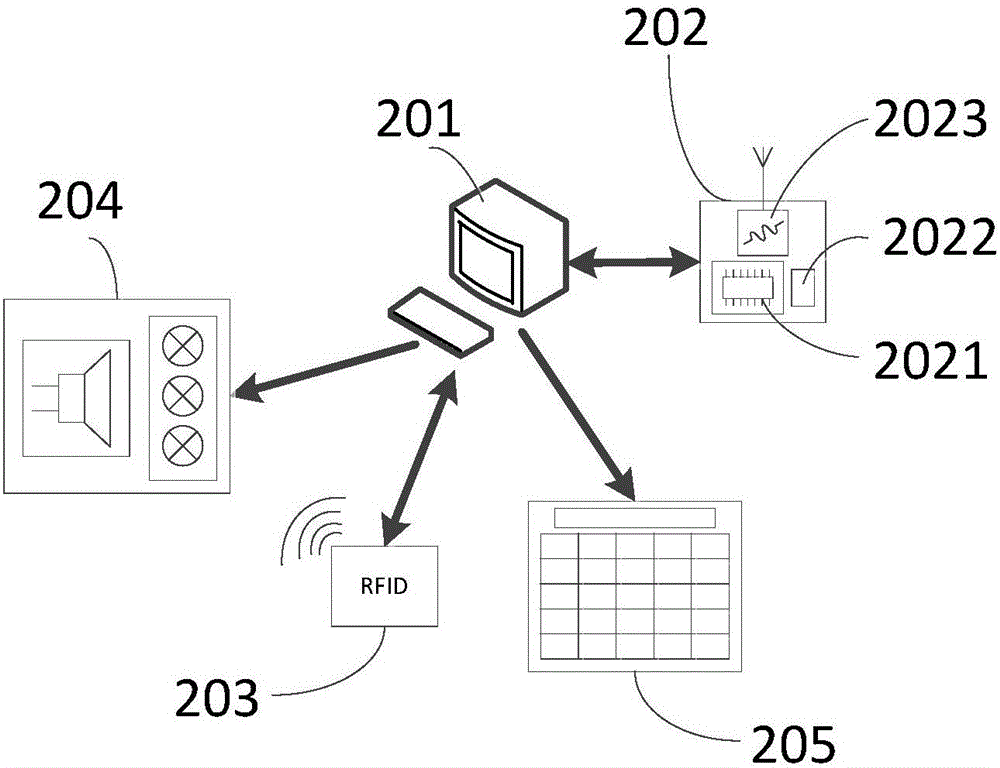

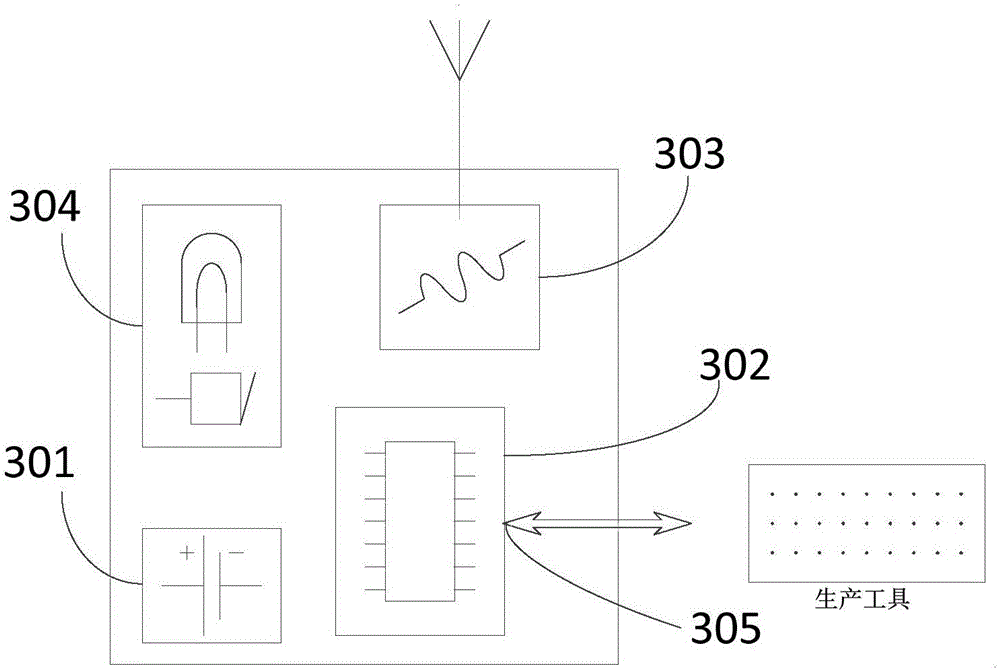

[0028] The intelligent manufacturing-oriented workshop dispatching agent group of the present invention integrates workshop on-site resources through the mutual cooperation and self-learning ability between the agent groups, so as to realize the automatic operation and processing of receiving, decentralizing, dispatching and implementing the production plan, further improving The intelligence of the workshop. The technical solution of the invention can also detect possible faults in the production process in real time, get rid of "information islands", realize the interconnection of workpieces, equipment and logistics tools in the workshop, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com