Control method for adjusting jig frequency automatically

A control method and automatic adjustment technology, applied in the field of control, can solve problems affecting oil production efficiency and personnel workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

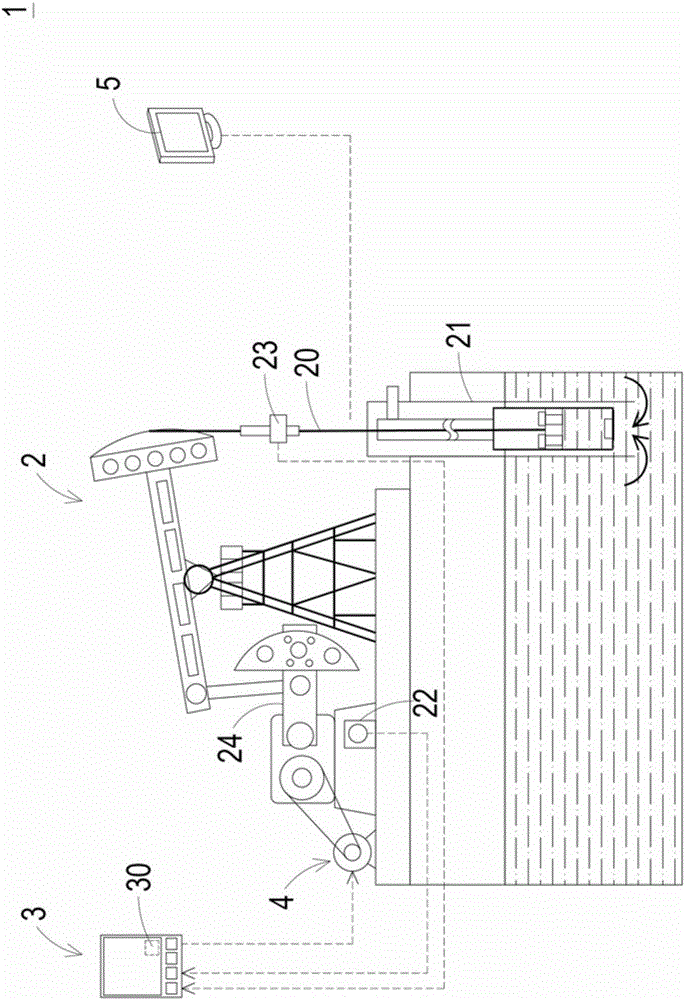

[0025] see figure 1 , which is a structural schematic diagram of a pumping unit driving system preferably implemented in the present invention. Such as figure 1 As shown, the pumping unit drive system 1 of this embodiment includes a pumping device 2 , a frequency converter 3 and a motor unit 4 . The frequency converter 3 has a control unit 30 for controlling the operating frequency of the frequency converter 3 so that the frequency converter 3 can correspondingly control the rotation speed of the motor unit 4 according to its own operating frequency. The motor unit 4 drives the oil pumping device 2 to operate, so that a sucker rod 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com