Test analysis method for tri-eccentric butterfly valve sealing pair and tri-eccentric butterfly valve

A technology of triple eccentric butterfly valve and analysis method, applied in instruments, measuring devices, mechanical measuring devices, etc., can solve the problem of uneven interference of the sealing pair of triple eccentric butterfly valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

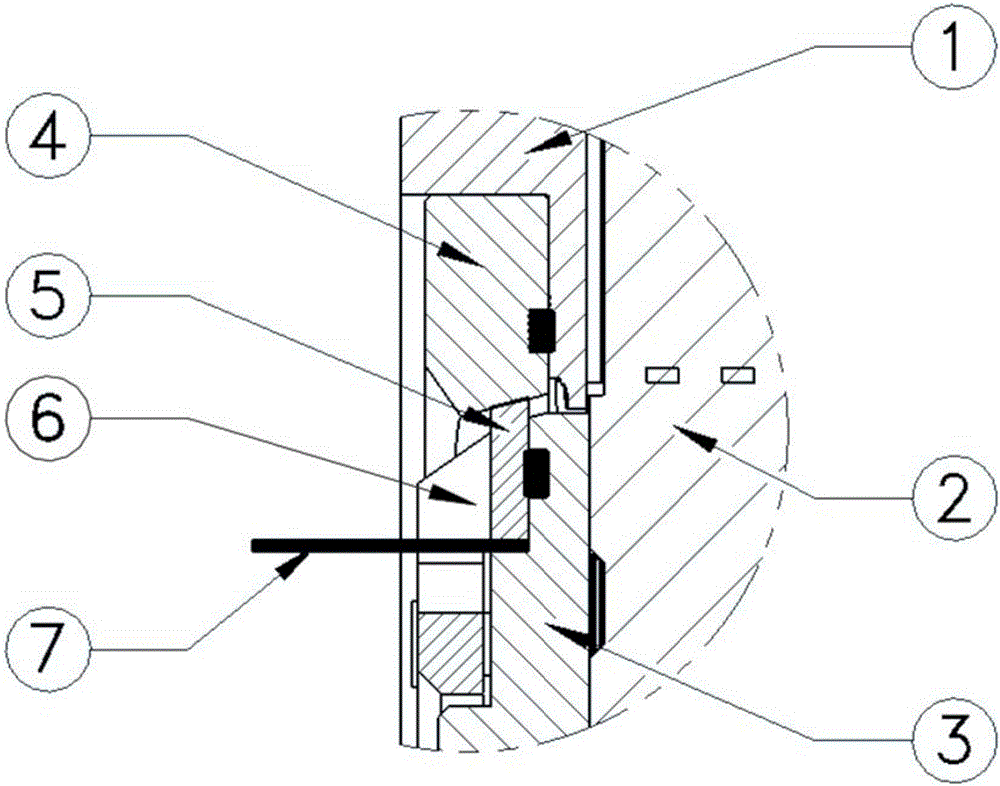

[0022] Embodiment 1: The present invention discloses a test and analysis method for the sealing pair of a triple eccentric butterfly valve (see attached figure 1 ), the triple eccentric butterfly valve includes a valve body 1, a valve plate 3, an annular metal valve seat 4 and a sealing ring 5; the metal valve seat 4 is fixed in the valve body 1; the valve plate 3 is installed on the metal valve In the seat 4, the valve rod 2 is pierced radially in the valve plate 3, and the sealing ring 5 is fixed on the outer peripheral edge of the valve plate 3; the valve seat 4 and the sealing ring 5 cooperate to form a sealing pair, and the sealing ring 5 is provided with a contact surface; it is characterized in that the triple eccentric butterfly valve is also provided with a retaining ring 6, the retaining ring 6 is set on the inner ring of the valve seat 4, and the retaining ring 6 contacts the sealing ring 5 and seals Circle 5 is limited; And comprises the following steps:

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com