Cooling fan compression joint device

A crimping device and cooling fan technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable pressing process, insufficient positioning accuracy of the lower fixture, and insufficient guiding accuracy of the lower fixture, so as to reduce rework Rate and scrap rate, reduce press-fitting alarms, and ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

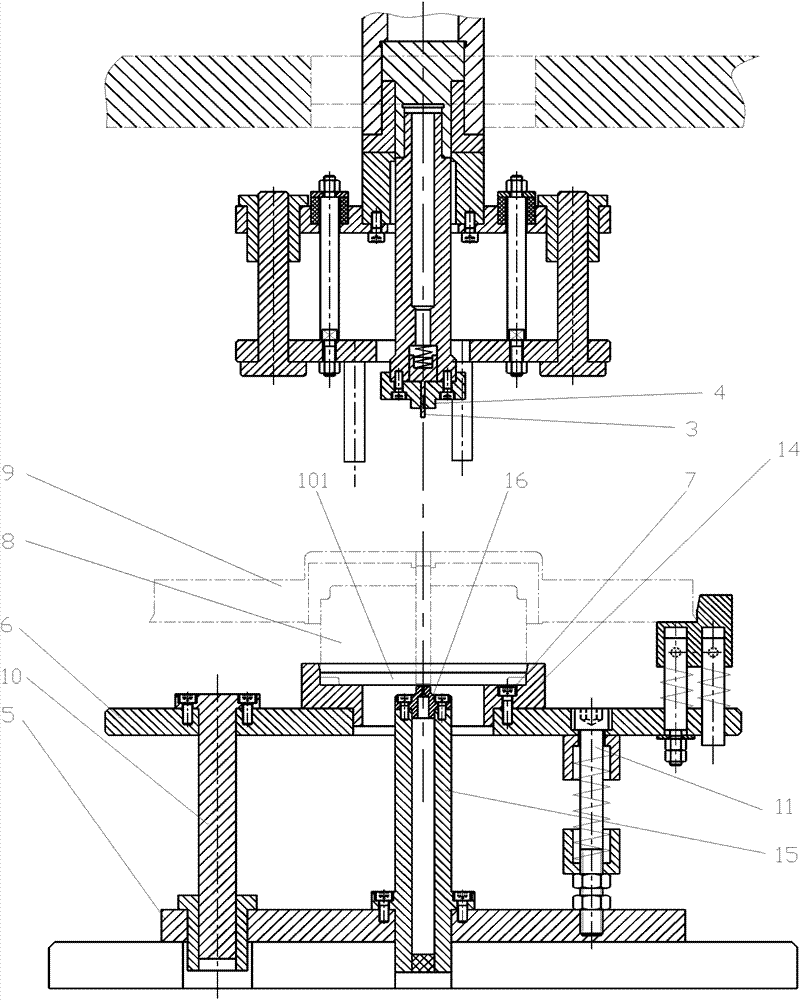

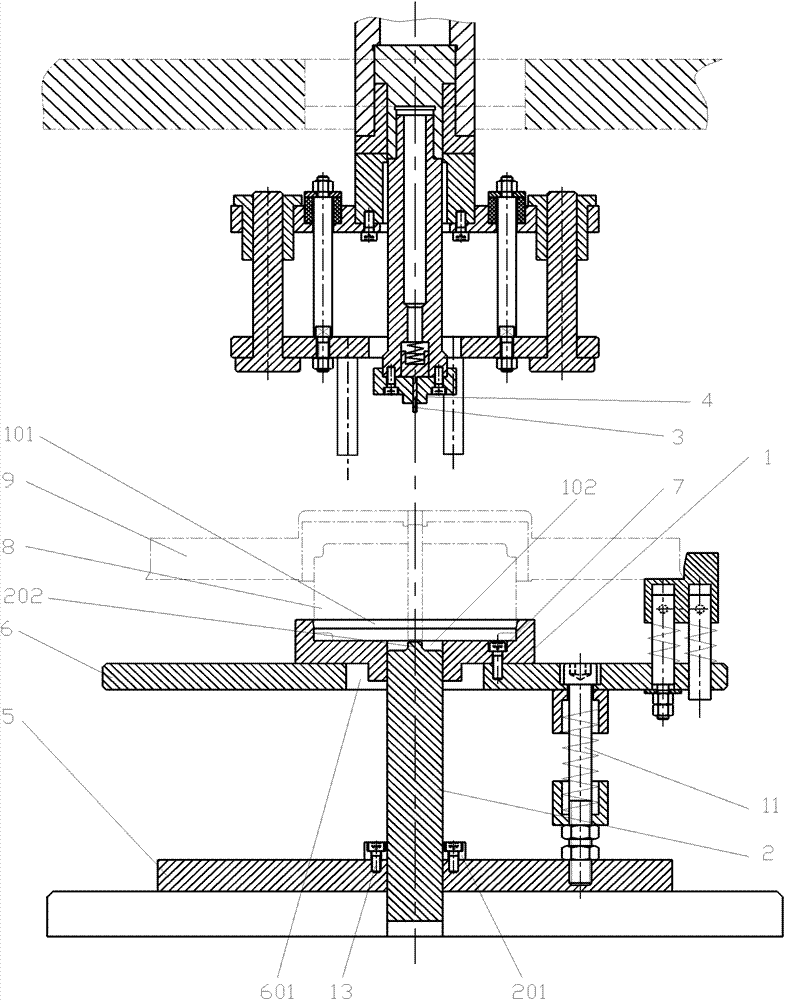

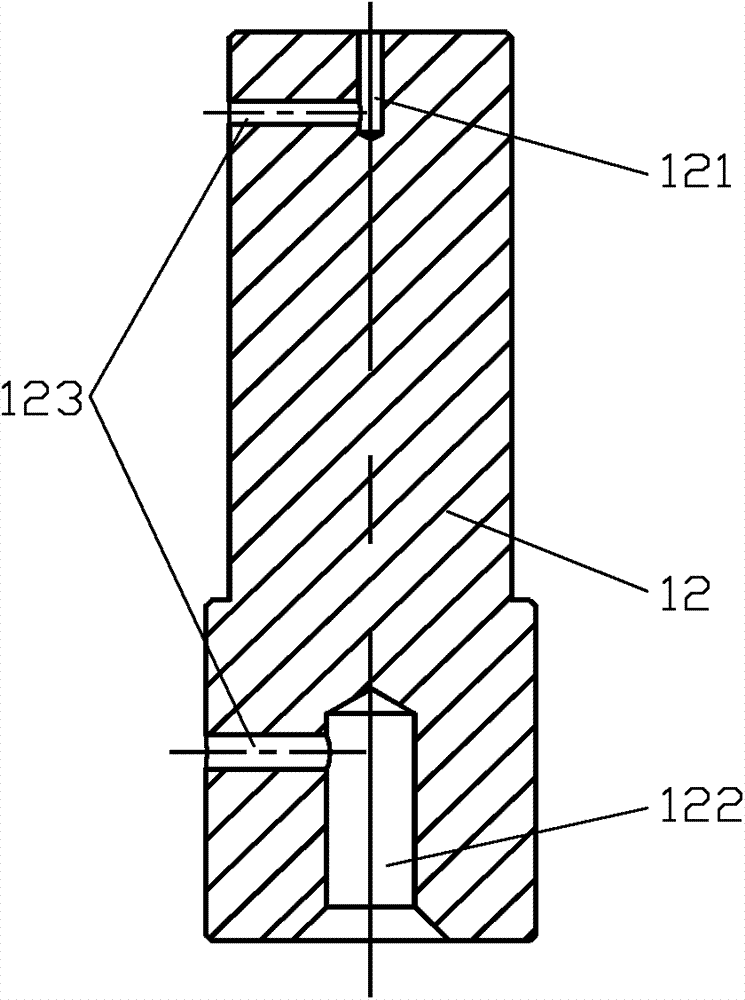

[0036] The currently used crimping device is to arrange a support plate 6 in parallel on the top of the horizontal base 5, the center of the support plate 6 is provided with an installation hole, and the existing lower clamp 14 in the shape of a stepped disc is arranged above the support plate 6. The small end extends into the installation hole and fits with the installation hole. The large end rests on the support plate 6 and is fixed with the support plate 6 by the locking bolt 7. The large end is provided with a motor positioning cavity 101, and the center of the small end is provided with a through hole. , the through hole communicates with the motor positioning cavity, a support rod 15 is arranged in the through hole, the outer diameter of the support rod 15 is smaller than the inner diameter of the through hole, the upper end of the support rod 15 is fixed with a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com