Integral mobile natural gas liquefaction device

A liquefaction device and natural gas technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve problems such as long construction period, difficulty in natural gas development, unreachable pipeline laying, etc., to improve the degree of automation, solve the problem of no water source, Easy to move and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

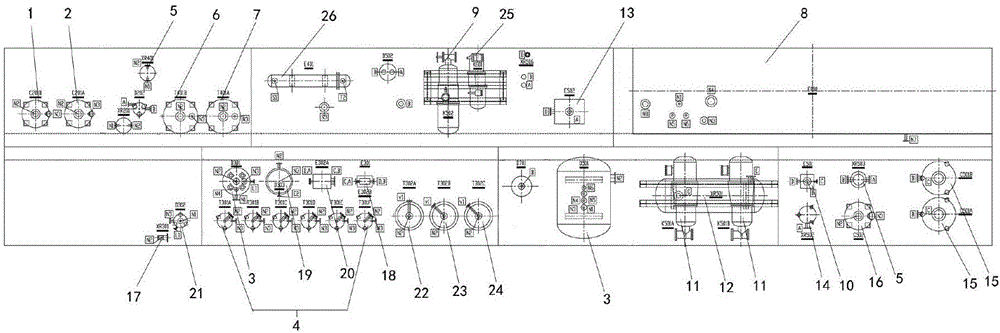

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as figure 1 As shown, the integrated mobile natural gas liquefaction unit is composed of a heavy hydrocarbon removal unit, a decarbonization unit, a dehydration unit, a liquefaction unit, an amine liquid regeneration unit, a cooling unit and public works in a mobile and integrated manner, of which:

[0028] The heavy hydrocarbon removal unit includes activated carbon purification tower A1 and activated carbon purification tower B2, and activated carbon purification tower A1 is connected with activated carbon purification tower B2;

[0029] The decarbonization unit includes a raw material gas-liquid separator 3, a decarbonization tower group 4, a dust filter 5 and a separation tank. The raw material gas-liquid separator 3 is connected to the decarbonization tower group 4, and the bottom of the decarboniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com