Drawer type suction port of integrated stove

A suction port and drawer-type technology, which is applied in the field of integrated stoves, can solve the problems that the top suction plate occupies a certain space, the air port is small, and the effect of blowing or smoking is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

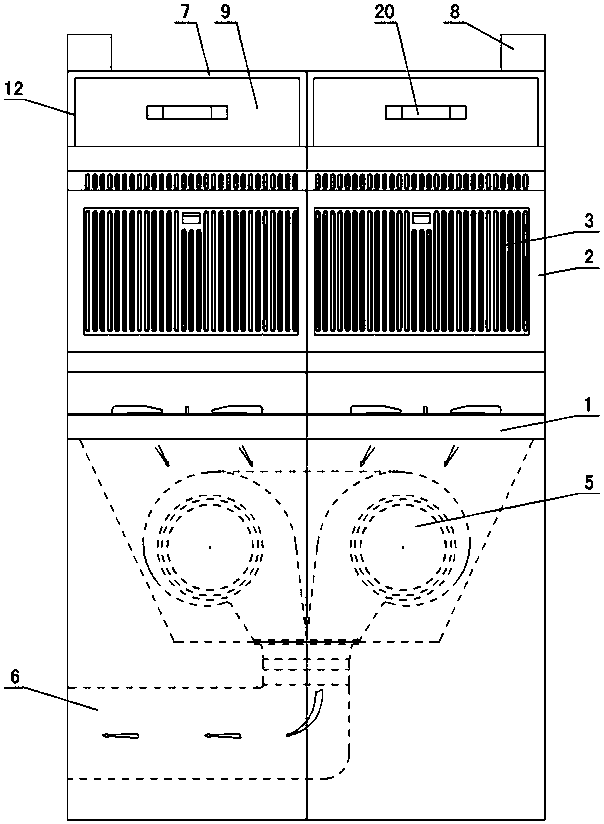

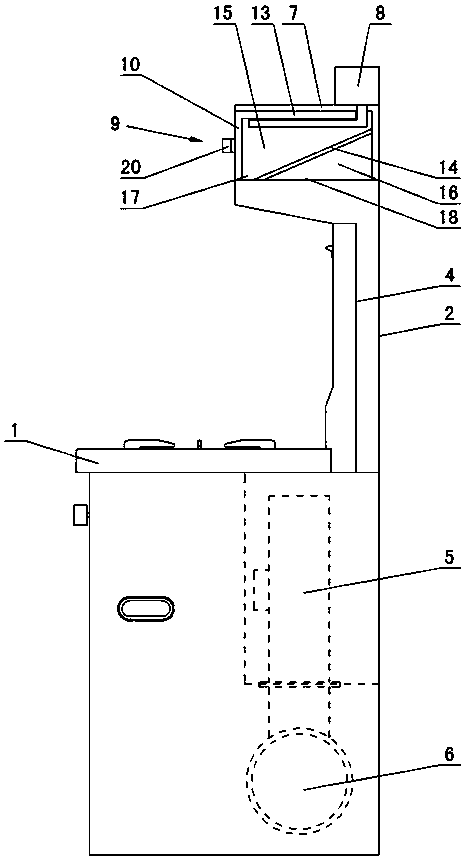

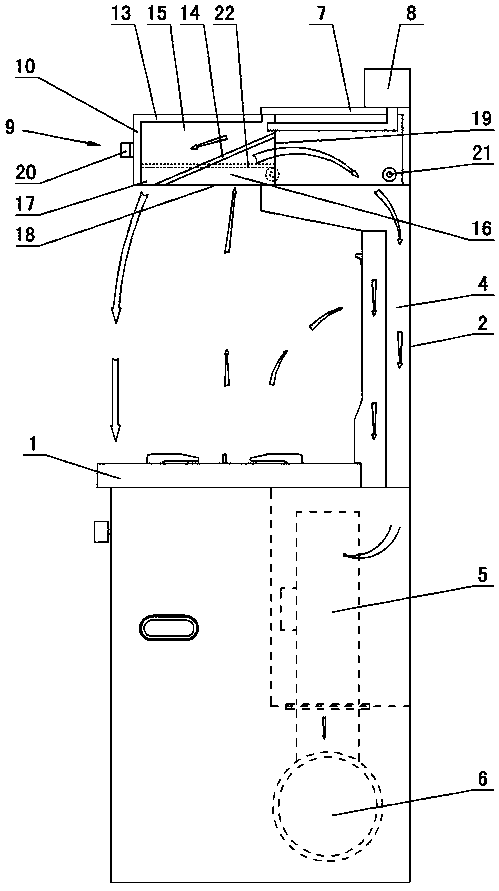

[0010] The invention relates to a drawer-type air suction port of an integrated stove, such as figure 1 — image 3 As shown, it includes a stove 1, a side suction plate 2 is arranged on the stove, a side suction hole 3 is formed on the wall of the side suction plate, an air suction channel 4 is opened in the side suction plate, a wind wheel 5 is arranged in the stove, The wind wheel is connected to the air outlet 6, and it is characterized in that: a top box 7 is arranged on the top of the side suction plate 2, an air curtain machine 8 is arranged on the top box, openings are formed on the front side and the lower side of the top box, and the top box Draw box 9 is set in the middle, and draw box is shaped on front baffle plate 10, both sides baffle plate 12 and upper baffle plate 13, and front baffle plate cooperates with the opening of top box front side, and inclined guide plate 14 is set in draw box, and inclined guide plate The inner cavity of the draw box 9 is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com