Internal combustion engine exhaust silencer capable of automatically following two working conditions

An exhaust muffler, automatic follow-up technology, applied in the direction of machine/engine, muffler, mechanical equipment, etc., to reduce exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

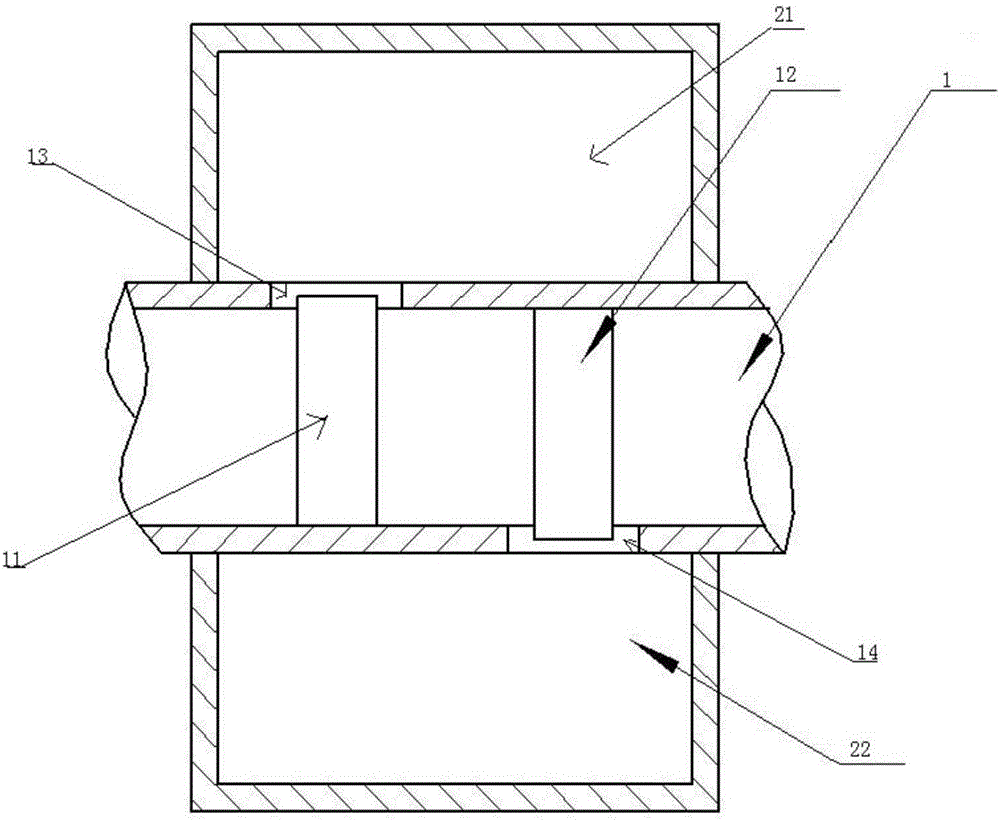

[0029] Refer below image 3 , 4 The exhaust muffler that automatically follows the two working conditions of the internal combustion engine of the present invention will be further described.

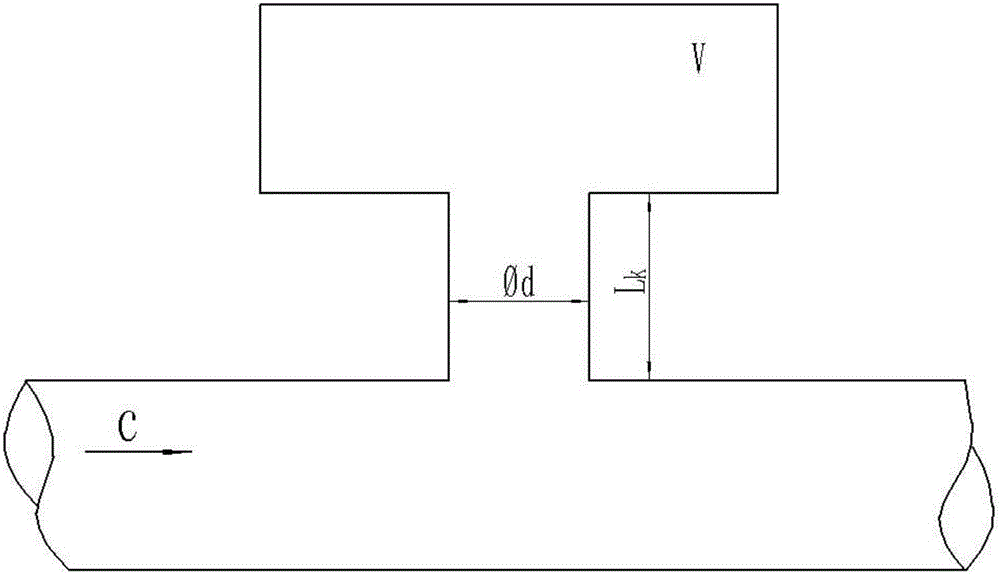

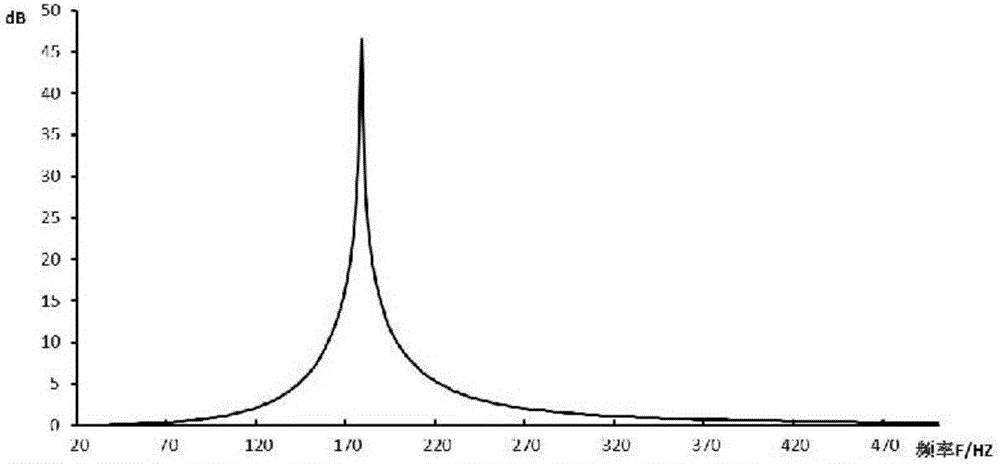

[0030] The exhaust muffler of the present invention, which automatically follows the two working conditions of the internal combustion engine, comprises a section of pipeline 1 and a first airtight resonant cavity 21 outside the pipeline 1 . The first circular hole 13 is opened on the wall of the pipeline 1, and the first circular hole 13 communicates with the inner cavity of the pipeline 1 and the first resonance cavity 21; on the inner wall of the pipeline 1 opposite to the first circular hole 13 A first cylinder 11 is provided, and the first cylinder 11 extends into the first circular hole 13 ; the expansion coefficient of the material used for the first cylinder 11 is smaller than that of the material used for the pipe 1 and the first resonant cavity 21 .

[0031] A second resonan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com