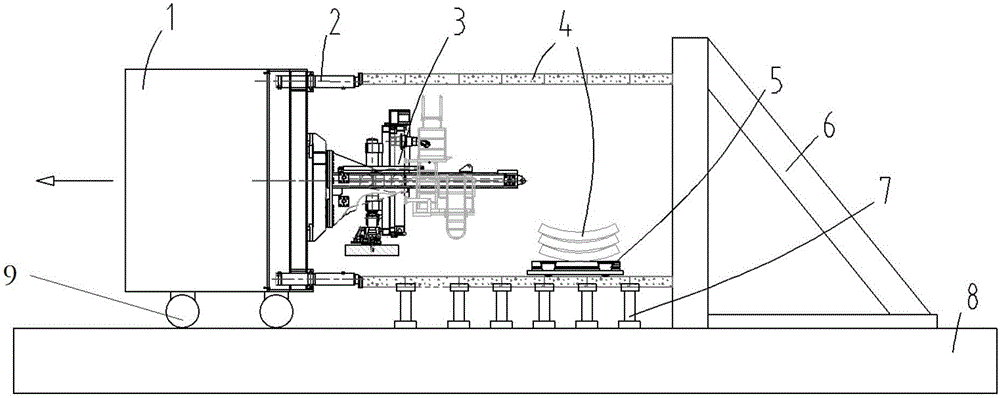

Duct piece assembly simulated experimental device

A technology for simulating experimental device and segment assembly, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of low quality and efficiency of segment assembly, and achieve the improvement of shield construction quality, assembly ability, and work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As mentioned in the background technology section, there is currently a lack of a segment assembly simulation experiment device that can train construction personnel, so it is easy to cause problems such as poor segment assembly quality and low efficiency.

[0020] On the basis of the above research, the embodiment of the present invention provides a segment assembly simulation experiment device. When the segment assembly machine has assembled a ring segment, the propulsion cylinder passes through its own extension, and at the end of the annular tunnel and Under the support of the segment propulsion reaction force bracket, the counterweight can be moved, and then the segment assembly machine fixed on the counterweight can be moved. When the segment assembly machine moves in place, the push cylinder can be retracted to facilitate Assemble the next segment. Among them, through the expansion and contraction of the oil cylinder, the moving distance of the segment assembly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com